Method for preparing near-infrared silver sulfide quantum dots by high-gravity reactor

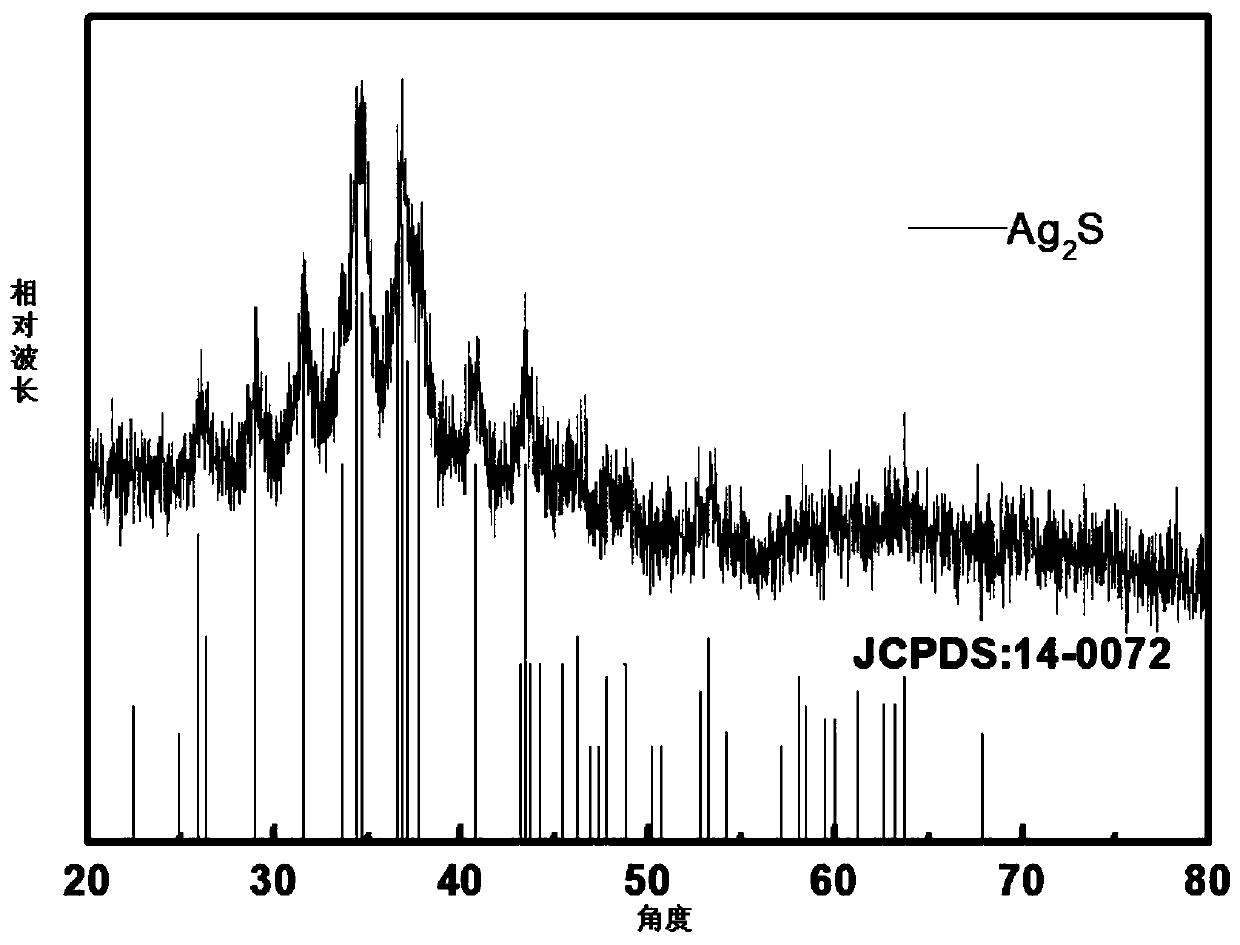

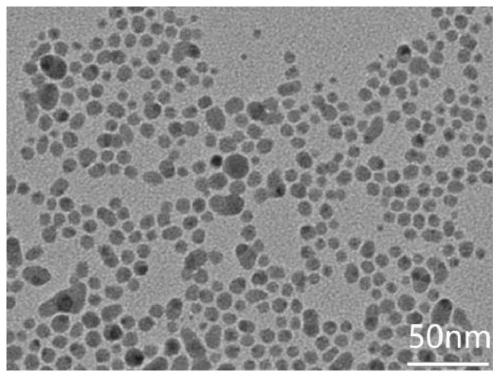

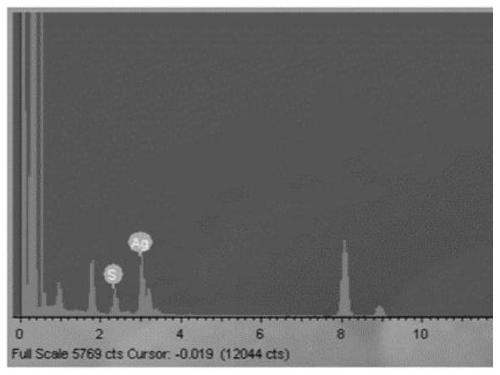

A high-gravity reactor and silver sulfide technology, which is applied in the interdisciplinary fields of chemical industry, materials and photonics, can solve the problems of poor controllability of quantum dots, and achieve the effects of narrow particle size distribution, good near-infrared fluorescence performance, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Measure 42.5ml of octadecene, 5ml of oleylamine, and 2.5ml of oleic acid into a 100ml beaker, add 0.168g of silver acetate, stir the solution at room temperature until it becomes clear, and record it as solution A. Measure 50ml of ultrapure water into a 100ml beaker, add 0.12g of sodium sulfide nonahydrate, 1ml of Tween 20, shake to dissolve, and record it as solution B. Adjust the rotation speed of the external circulation high gravity rotating packed bed to 1000rpm, pass the A and B solutions into the external circulation high gravity rotating packed bed through the peristaltic pump, set the feed flow rate of the A solution and the B solution to 1:1, The feeding rate of the peristaltic pump is 20rpm. After all the raw material solution is passed into the outer circulation supergravity rotating packed bed, the discharged solution is collected, washed 5 times by centrifugal washing with absolute ethanol, and the obtained product is placed in a drying box for 60 °C for 8...

Embodiment 2

[0027] Measure 42.5ml of octadecene, 5ml of oleylamine, and 2.5ml of oleic acid into a 100ml beaker, add 0.168g of silver acetate, stir the solution at room temperature until it becomes clear, and record it as solution A. Measure 50ml of ultrapure water into a 100ml beaker, add 0.12g of sodium sulfide nonahydrate, 1ml of Tween 20, shake to dissolve, and record it as solution B. Adjust the rotation speed of the external circulation high gravity rotating packed bed to 1000rpm, pass the A and B solutions into the external circulation high gravity rotating packed bed through the peristaltic pump, set the feed flow rate of the A solution and the B solution to 1:1, The feeding rate of the peristaltic pump is 70rpm. After all the raw material solution is passed into the outer circulation supergravity rotating packed bed, the discharged solution is collected, washed 5 times by centrifugal washing with absolute ethanol, and the obtained product is placed in a drying box for 60 °C for 8...

Embodiment 3

[0029] Measure 42.5ml of octadecene, 5ml of oleylamine, and 2.5ml of oleic acid into a 100ml beaker, add 0.168g of silver acetate, stir the solution at room temperature until it becomes clear, and record it as solution A. Measure 50ml of ultrapure water into a 100ml beaker, add 0.12g of sodium sulfide nonahydrate, 1ml of Tween 20, shake to dissolve, and record it as solution B. Adjust the rotation speed of the external circulation high gravity rotating packed bed to 1000rpm, pass the A and B solutions into the external circulation high gravity rotating packed bed through the peristaltic pump, set the feed flow rate of the A solution and the B solution to 1:1, The feeding rate of the peristaltic pump is 120rpm. After all the raw material solution is passed into the outer circulation supergravity rotating packed bed, the discharged solution is collected, washed 5 times by centrifugal washing with absolute ethanol, and the obtained product is placed in a drying box for 60 °C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com