Packing machine for primary and secondary fusion complete switch testing equipment

A switch test and baler technology, applied in the field of balers, can solve problems such as packaging efficiency, and achieve the effect of meeting the needs of use, compact structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

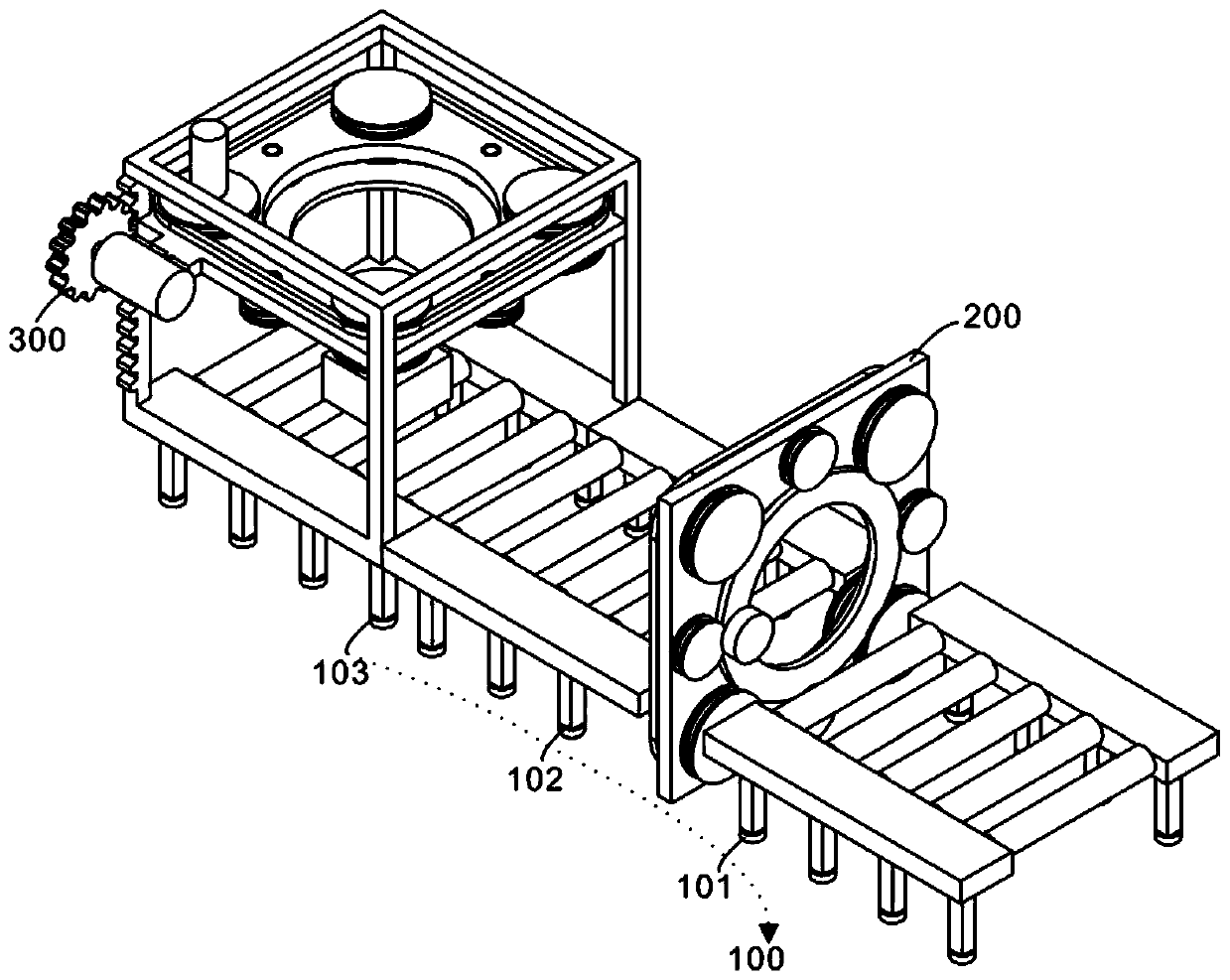

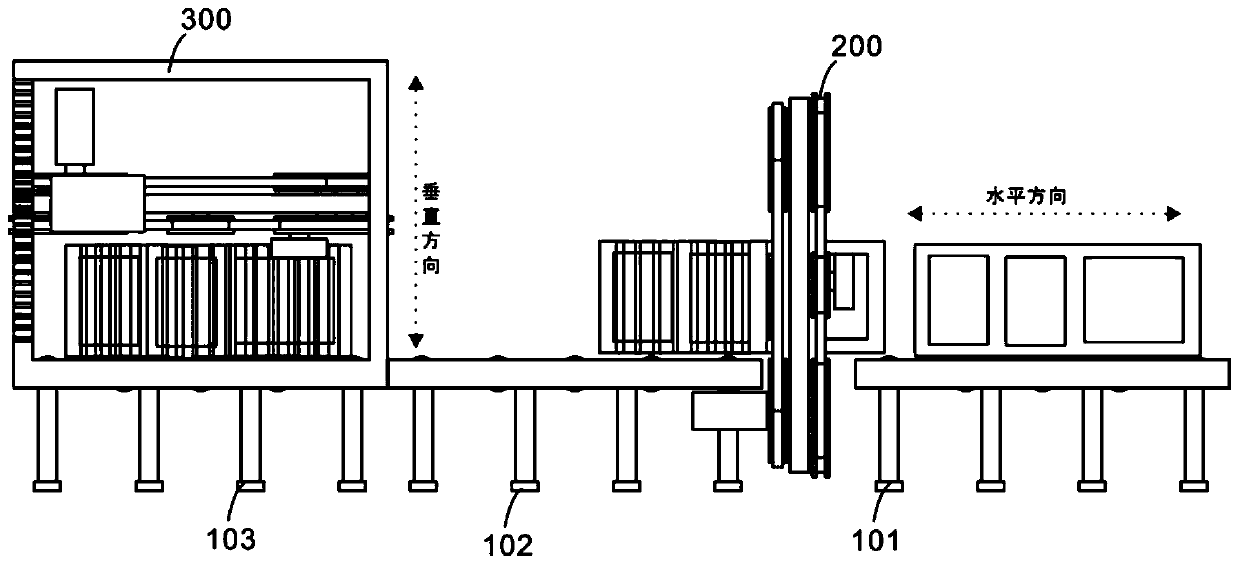

[0042] refer to figure 1 , provides a schematic diagram of the overall structure of a packaging machine for a complete set of switch test equipment for primary and secondary fusion, as shown in figure 1 , a packing machine for primary and secondary fusion complete sets of switch test equipment includes a conveying assembly 100, which is divided into a first conveyor 101, a second conveyor 102 and a third conveyor 103, and the two ends of the third conveyor 103 are respectively connected to The first conveyor 101 is adjacent to the second conveyor 102; the horizontal winding assembly 200 is arranged between the first conveyor 101 and the second conveyor 102; and the vertical winding assembly 300 is arranged above the third conveyor 103 .

[0043] Specifically, the main structure of the present invention includes a conveying assembly 100, a horizontal winding assembly 200, and a vertical winding assembly 300. Through the cooperation between the conveying assembly 100, the horiz...

Embodiment 2

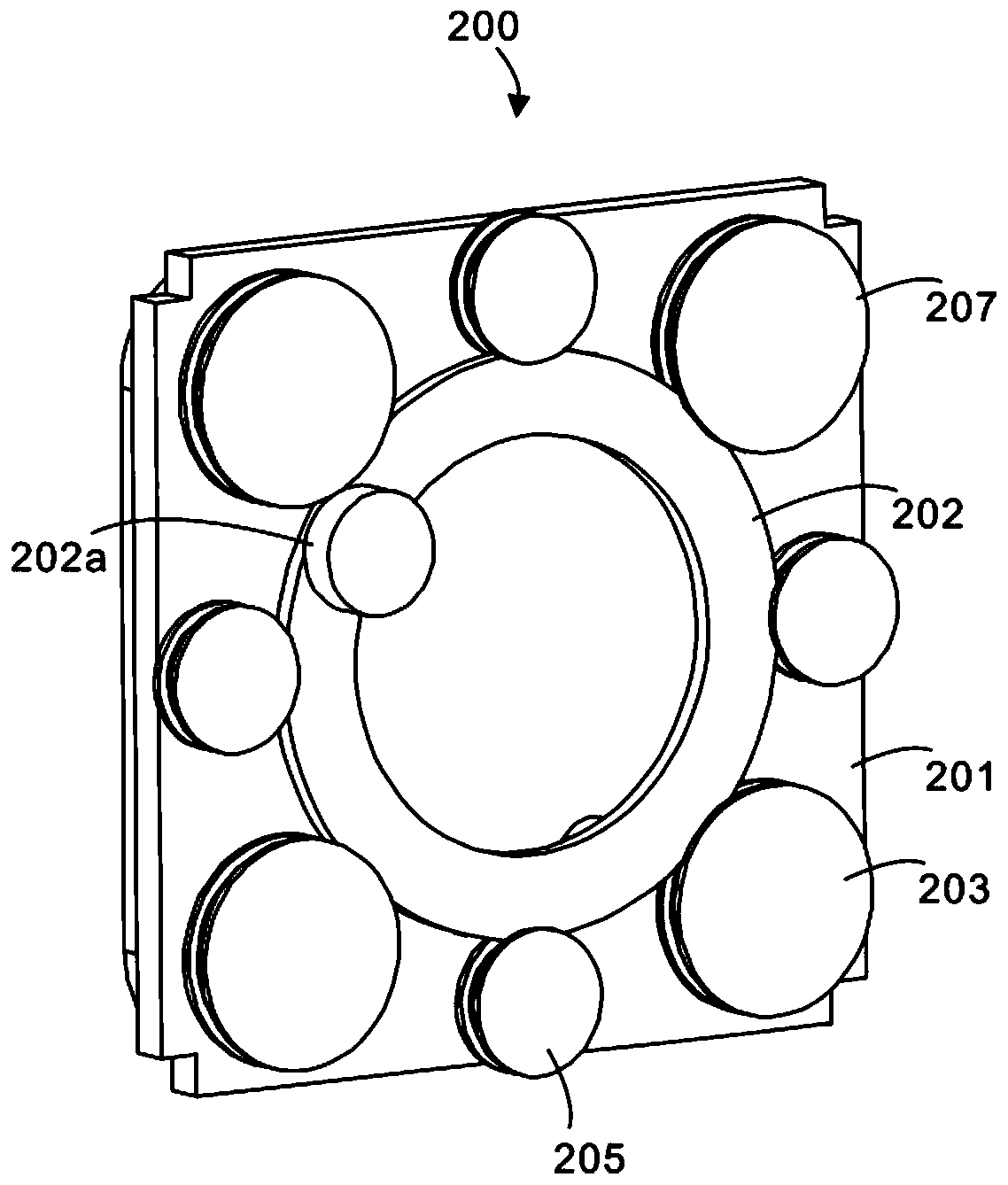

[0047] refer to Figure 2-4 , this embodiment is different from the first embodiment in that: the horizontal winding assembly 200 includes a first bracket 201, a swivel 202, a rotating drive member 203, a first drive motor 204 and a stopper 205, through which the first bracket 201 , the rotating body 202 , the rotating driving member 203 , the first driving motor 204 and the limiting member 205 cooperate with each other to package the horizontal outer wall of the testing device. Specifically, the horizontal winding assembly 200 includes a first bracket 201, a swivel body 202, a rotating drive member 203, a first drive motor 204 and a limiting member 205, and the first bracket 201 is used for carrying, rotating the driving member 203 and the limiting member 205 , the rotating driving part 203 and the limiting part 205 are installed on the first bracket 201, and the rotating driving part 203 and the limiting part 205 are matched with the swivel body 202, wherein the swivel body ...

Embodiment 3

[0053] refer to image 3 , 4 And 7, this embodiment is different from the above embodiments in that: the horizontal winding assembly 200 also includes a transmission member 207 and a conveyor belt 208, and the mutual cooperation between the transmission member 207 and the conveyor belt 208 ensures the stability of the transmission of the horizontal winding assembly 200 sex. Specifically, the horizontal winding assembly 200 also includes a transmission member 207 and a conveyor belt 208. In this embodiment, there are three transmission members 207 in total, and the three transmission members 207 and the rotating drive member 203 are all installed on the first bracket 201 and evenly distributed. On the outside of the second central hole 201a, the three transmission parts 207 are connected to the rotating drive part 203 through a conveyor belt 208. The end edges of the body 202 are embedded in the slots 203b-1 of the three transmission parts 207 and the rotating driving part 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com