One-drive-two numerically controlled machining tool of multi-axis truss robot for large piston pin

A truss robot and piston pin technology, applied in metal processing and other directions, can solve problems such as reducing the production efficiency of enterprises, increasing production and processing time and staff workload, and cumbersome operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

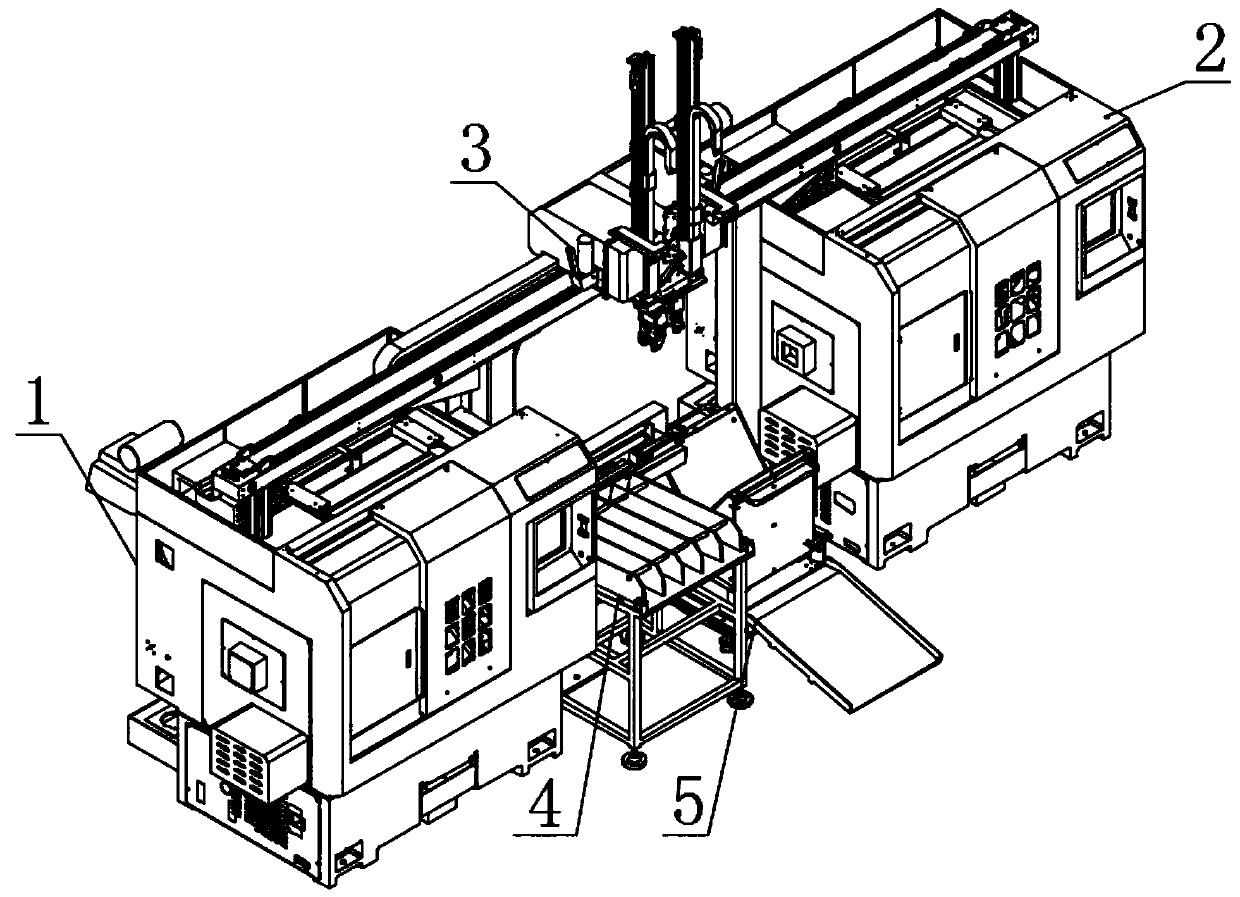

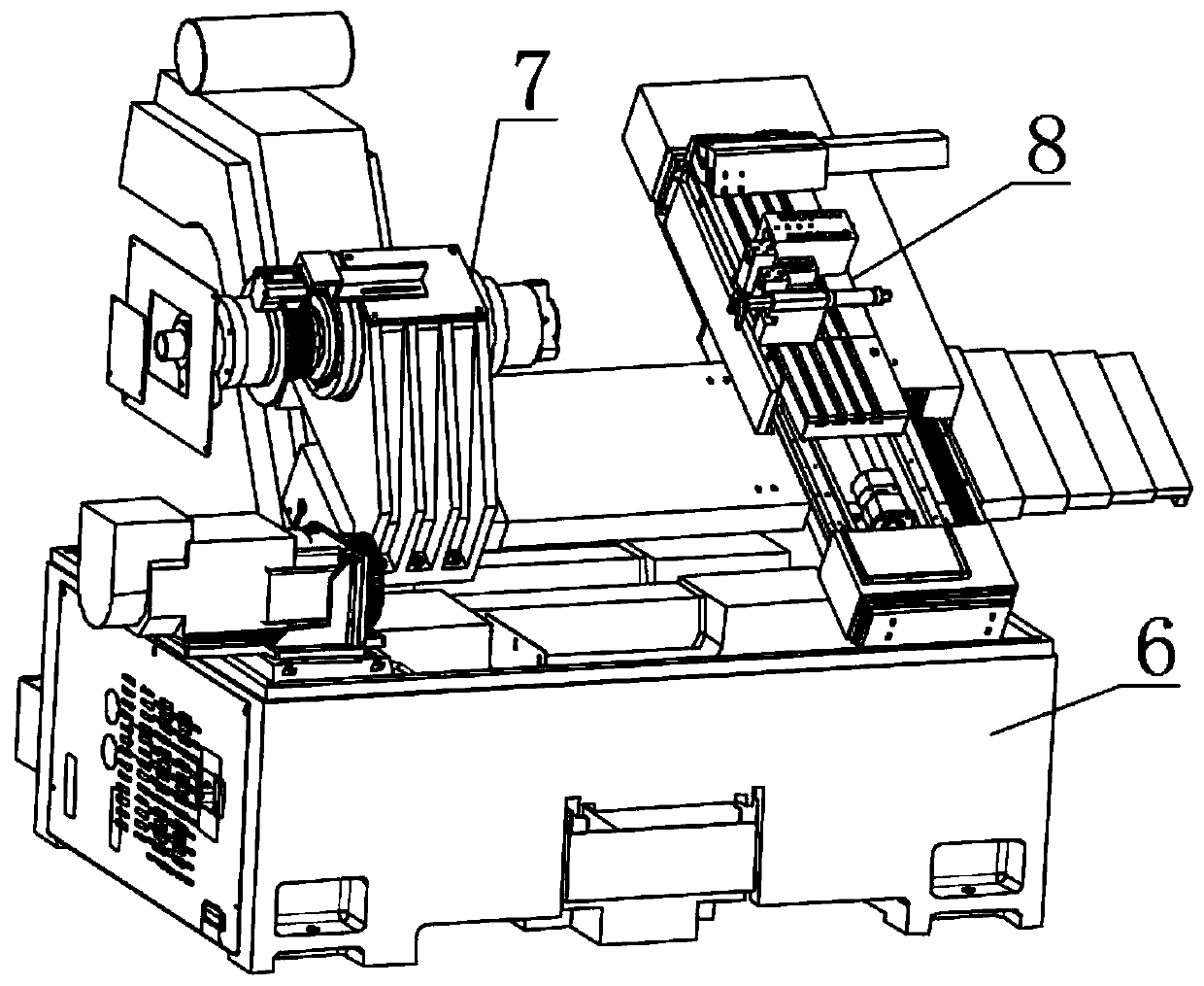

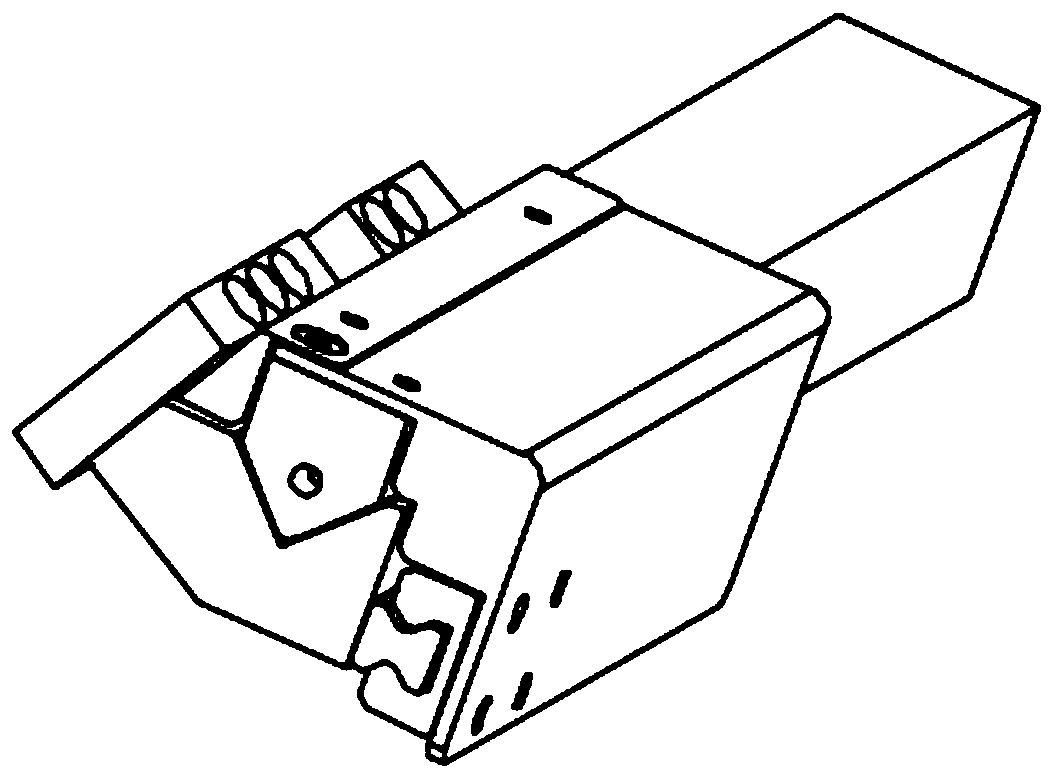

[0025] like Figures 1 to 9 As shown, a multi-axis truss robot one-to-two CNC machining machine for large piston pins, including a first piston pin CNC machine 1, a second piston pin CNC machine 2, a beam robot 3, a storage hoist 4 and a receiving storage machine 5. The first piston pin numerical control machine 1, the material storage hoist 4, the receiving storage machine 5 and the second piston pin numerical control machine 2 are arranged in sequence, and the first piston pin numerical control machine 1 and the second piston pin numerical control machine 2 are two All of them are equipped with a trough mechanism, and through the trough mechanism, the beam robot 3 is used to carry out the feeding and unloading work of the machine tool processing....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com