Steel ring machining equipment integrating foot pressing and chamfering

A technology for processing equipment and steel rings, applied in the field of steel ring manufacturing and processing, can solve problems such as low efficiency, production needs to be improved, injuries, etc., and achieve the effects of improving safety and work efficiency, reducing labor intensity of workers, and realizing processing automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

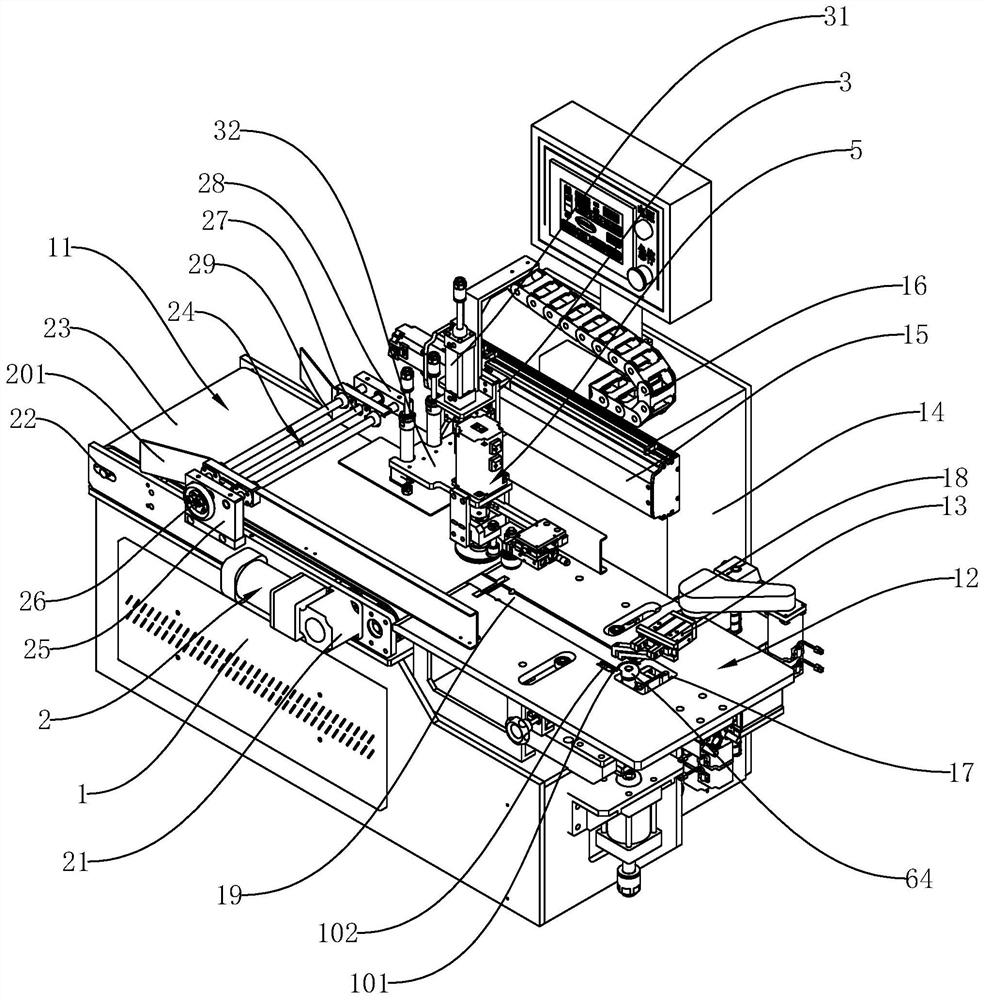

[0035] Embodiment 1: As shown in the figure, a steel ring processing equipment integrating presser foot and chamfering, including

[0036] A frame 1 with a feeding area 11 and a processing area 12 on the frame 1;

[0037] A feeding mechanism 2, the feeding mechanism 2 is arranged at the feeding area 11, and is used to transport the steel rings to be processed to the processing area 12 one by one;

[0038] A mobile frame 3, the mobile frame 3 can move back and forth and be arranged on the frame 1;

[0039] A lifting plate 32, the lifting plate 32 can move up and down and is arranged on the moving frame 3;

[0040] A pressing plate 38, the pressing plate 38 is arranged on the lifting plate 32 by the lifting mechanism, and is used for contacting with the steel ring to be processed;

[0041] An inner chamfering wheel 4, the inner chamfering wheel 4 is rotatably arranged on the lifting plate 32;

[0042] An outer chamfering wheel 42, the outer chamfering wheel 42 can move forwar...

Embodiment 2

[0046] Embodiment 2: As shown in the figure, other structures are the same as Embodiment 1, and the difference is that the feeding mechanism 2 includes a conveying power unit 21, two roller shafts 22 and a belt wound between the two roller shafts 22. Conveyor belt 23, two roller shafts 22 are rotatably arranged on the frame 1 at an interval front and back, and the conveying power unit 21 is arranged on the frame 1, and is used to drive one of the roller shafts 22 to rotate, and the feeding area 11 is also provided with The material guide mechanism 24, the material guide mechanism 24 comprises a first base 25, a first adjustment hand wheel 26, a first two-way screw mandrel 27, a second base 28, two guide shafts 29 and two material guide plates 201, the first A pedestal 25 and a second pedestal 28 are respectively fixed at the feeding area 11 at left and right intervals, and two guide shafts 29 are respectively connected between the first pedestal 25 and the second pedestal 28, a...

Embodiment 3

[0048] Embodiment 3: As shown in the figure, other structures are the same as Embodiment 2. The difference is that a support 36 is fixed at the lower end of the lifting plate 32, and the rotating mechanism 5 includes a rotating motor 51, a rotating rod 52 and a first bearing 53. The first bearing 53 is arranged on the support 36, and the rotating motor 51 is fixed on the lifting plate 32. Presser caster 6 is fixed. In this structure, the rotating motor 51 is fixed on the lifting plate 32, and it moves synchronously with the lifting plate 32. When the rotating motor 51 rotates, it drives the rotating rod 52 to rotate, so that the inner presser caster 6 connected with the rotating rod 52 rotates synchronously. The structure is simple and practical.

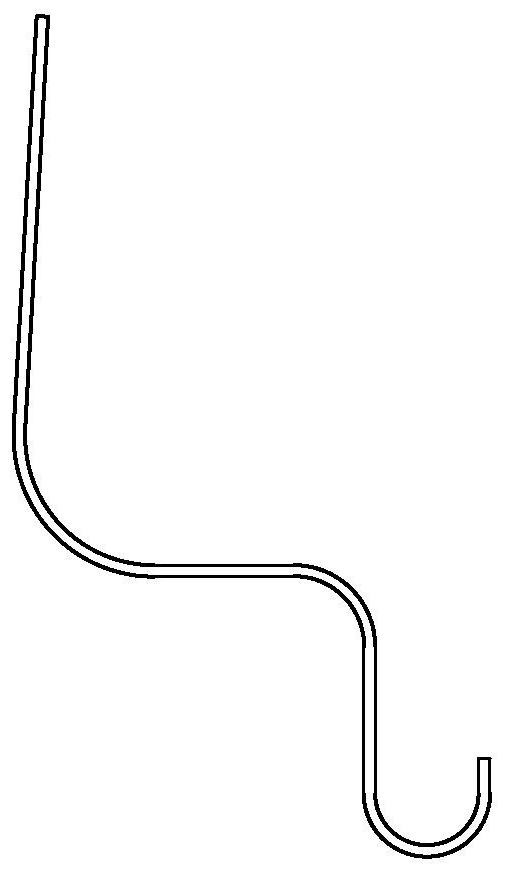

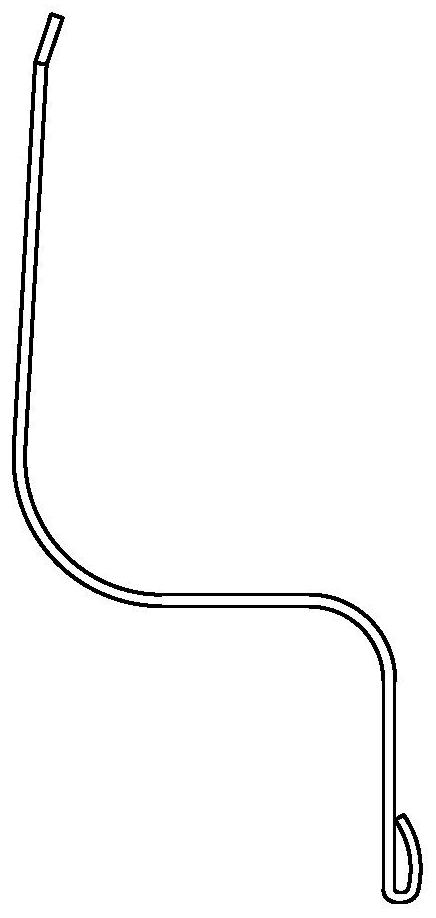

[0049] The inner presser caster wheel 6 includes a mutually fixed retaining ring portion 61 and a presser foot portion 62 from top to bottom. The diameter of the retaining ring portion 61 is greater than the diameter of the presser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com