UiO-66-NH2 composite material used for palladium adsorption and preparation method thereof

A technology of uio-66-nh2 and composite materials, which is applied in chemical instruments and methods, and other chemical processes, to achieve the effect of improving fluid mechanical properties and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

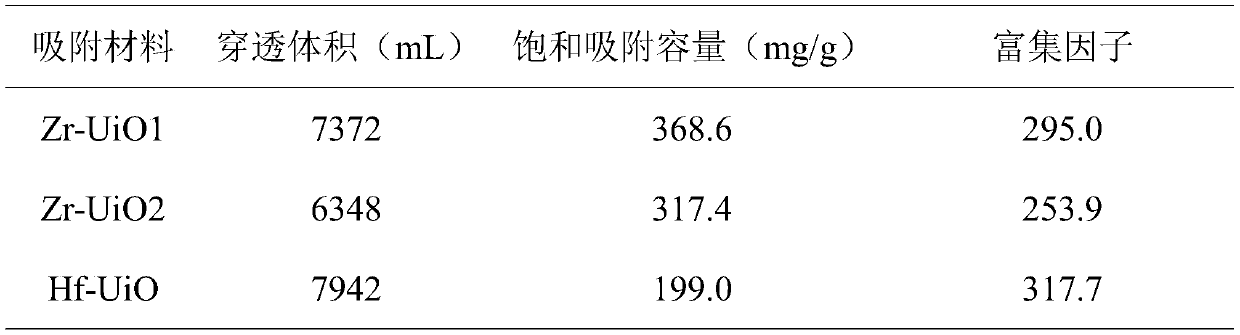

Embodiment 1

[0022] Add 6.9g of zirconium nitrate (pentahydrate) and 4.2g of 2-aminoterephthalic acid to a round bottom flask, then add a mixed solvent of 120mL of water and 30mL of acetic acid, ultrasonically disperse for 5 minutes, then stir and reflux at 110°C for 2 hours , cool to room temperature, add 36mL of sodium alginate aqueous solution with a mass concentration of 0.5% to the mixed solution, mix well, add hydrochloric acid dropwise to adjust the pH value to below 1, and soak the precipitate obtained by suction filtration with washing liquid water and acetone in turn , the obtained solid was vacuum dried at 120°C for 8 hours, and the zirconium-based UiO-66-NH 2 Composite material, labeled Zr-UiO1.

Embodiment 2

[0024] The operation steps are the same as in Example 1, the difference is that the preparation of zirconium-based UiO-66-NH 2 When making composite materials, replace zirconium nitrate (pentahydrate) with 3.7g of zirconium chloride as a metal salt, and the final zirconium-based UiO-66-NH 2 The composite material is labeled Zr-UiO2.

Embodiment 3

[0026] Add 8.4g hafnium chloride and 4.5g 2-aminoterephthalic acid to the round bottom flask, then add a mixed solvent consisting of 90mL water and 60mL acetic acid, ultrasonically disperse for 10 minutes, stir and reflux at 120°C for 12 hours, and cool to At room temperature, add 30mL of sodium alginate aqueous solution with a mass concentration of 1% to the mixed solution, mix well, add hydrochloric acid dropwise to adjust the pH value to below 1, and filter the obtained precipitate with washing liquid methanol and acetone successively. The obtained solid was vacuum-dried at 120°C for 8 hours to obtain the hafnium-based UiO-66-NH 2 composite, labeled Hf-UiO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com