Large-tonnage soft wire lift insulation tool and manufacturing method thereof

An insulating tool, large tonnage technology, used in overhead lines/cable equipment, textile cables, textiles and papermaking, etc., can solve problems such as easy breakage, avoid stress concentration, facilitate transportation, and prevent cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

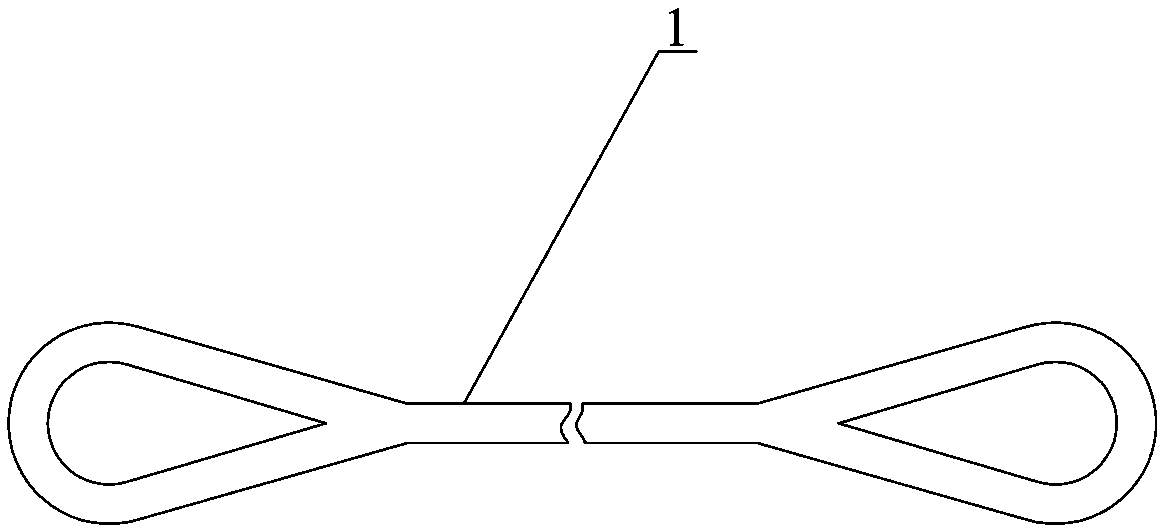

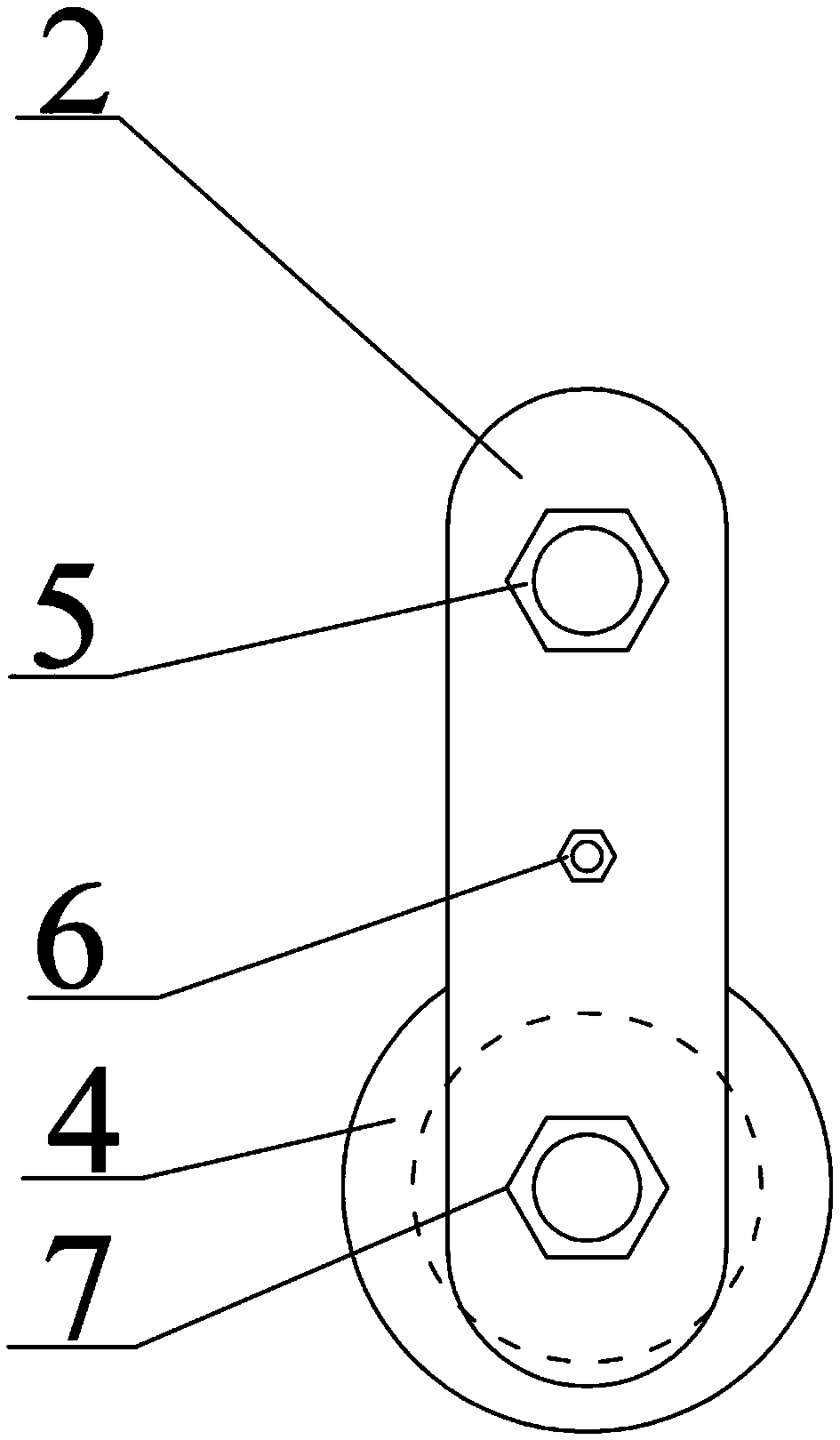

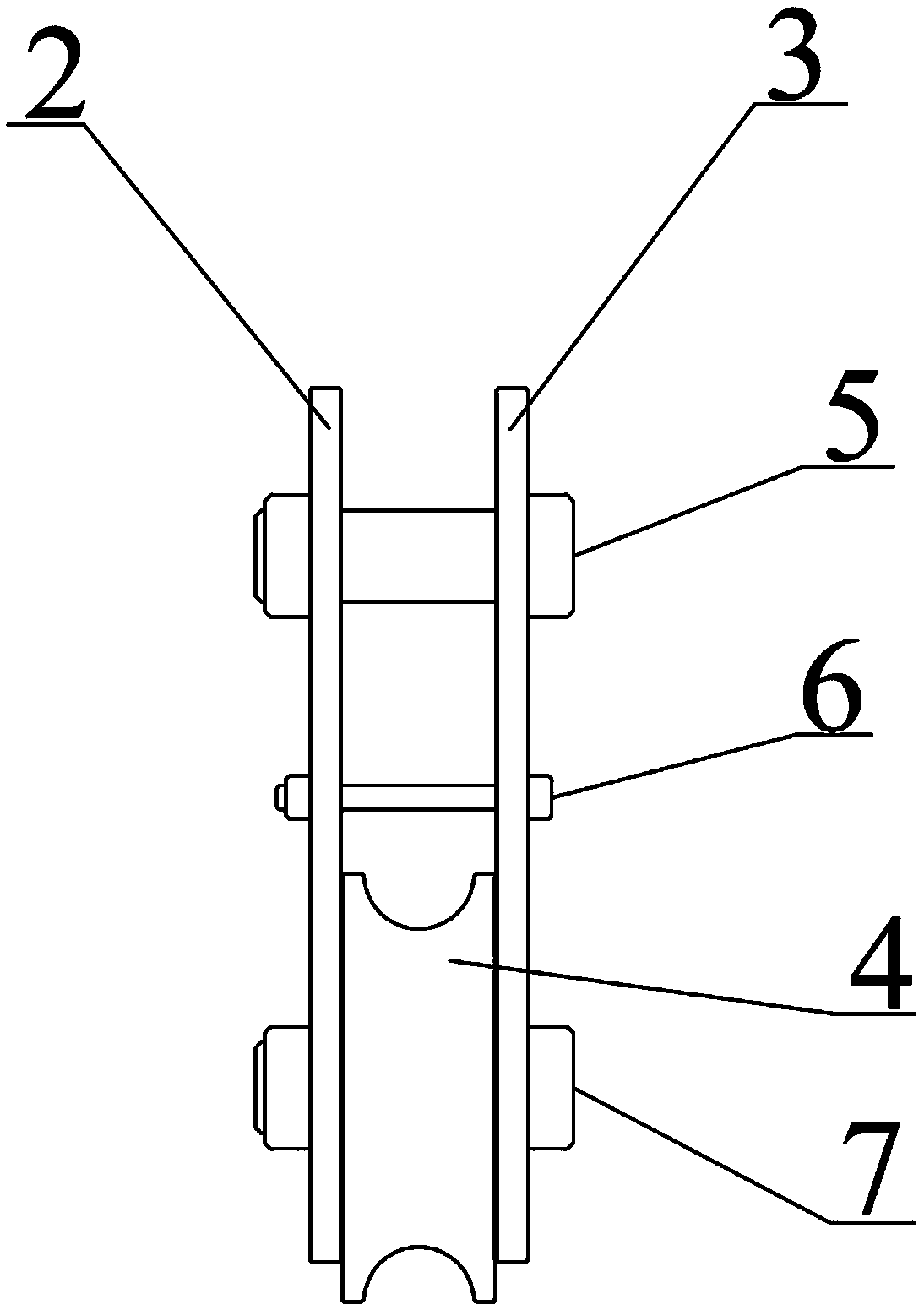

[0034] see Figure 1-4 , a large-tonnage soft wire-lifting insulation tool, including a soft pull rod 1 and a connector, the two ends of the soft pull rod are ring-shaped, and the soft pull rod includes an inner core and a coating on The sheath outside the inner core, the inner core is made of 12 strands of PBO fiber, the material of the sheath is moisture-proof silk thread; the connector includes a left side plate 2, a right side plate 3, a pulley 4 and Connect and fix the fixing parts of the left side board 2 and the right side board 3, the pulley 4 is arranged between the left side board 2 and the right side board 3, the described fixing parts include bolts and nuts, and the described left side board 2. The right side plate 3 is respectively provided with fixing holes 8 matching the bolts of the fixing parts. The fixing parts are provided in three groups, namely, the first group of fixing parts 5, the second group of fixing parts 6, the third group of fixing parts 7, and th...

Embodiment 2

[0046] see Figure 1-4 , a large-tonnage soft wire-lifting insulation tool, including a soft pull rod 1 and a connector, the two ends of the soft pull rod are ring-shaped, and the soft pull rod includes an inner core and a coating on The sheath outside the inner core, the inner core is made of 12 strands of PBO fiber, the material of the sheath is moisture-proof silk thread; the connector includes a left side plate 2, a right side plate 3, a pulley 4 and Connect and fix the fixing parts of the left side board 2 and the right side board 3, the pulley 4 is arranged between the left side board 2 and the right side board 3, the described fixing parts include bolts and nuts, and the described left side board 2. The right side plate 3 is respectively provided with fixing holes 8 matching the bolts of the fixing parts. The fixing parts are provided in three groups, namely, the first group of fixing parts 5, the second group of fixing parts 6, the third group of fixing parts 7, and th...

Embodiment 3

[0053] see Figure 1-4 , a large-tonnage soft wire-lifting insulation tool, including a soft pull rod 1 and a connector, the two ends of the soft pull rod are ring-shaped, and the soft pull rod includes an inner core and a coating on The sheath outside the inner core, the inner core is made of 12 strands of aramid fibers, and the material of the sheath is moisture-proof silk thread; the connector includes a left side plate 2, a right side plate 3, and a pulley 4 And connect and fix the fixing piece of left side plate 2, right side plate 3, described pulley 4 is arranged between left side plate 2 and right side plate 3, described fixing piece comprises bolt and nut, described left side The plate 2 and the right side plate 3 are respectively provided with fixing holes 8 matching the bolts of the fixing parts. The fixing parts are provided in three groups, namely the first group of fixing parts 5, the second group of fixing parts 6, and the third group of fixing parts 7. The thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com