A water-lubricated screw compressor bearing structure

A water-lubricated, thrust sliding bearing technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., to reduce the trouble of installation, commissioning and maintenance, increase the force contact area, and reduce the difficulty of after-sales service

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

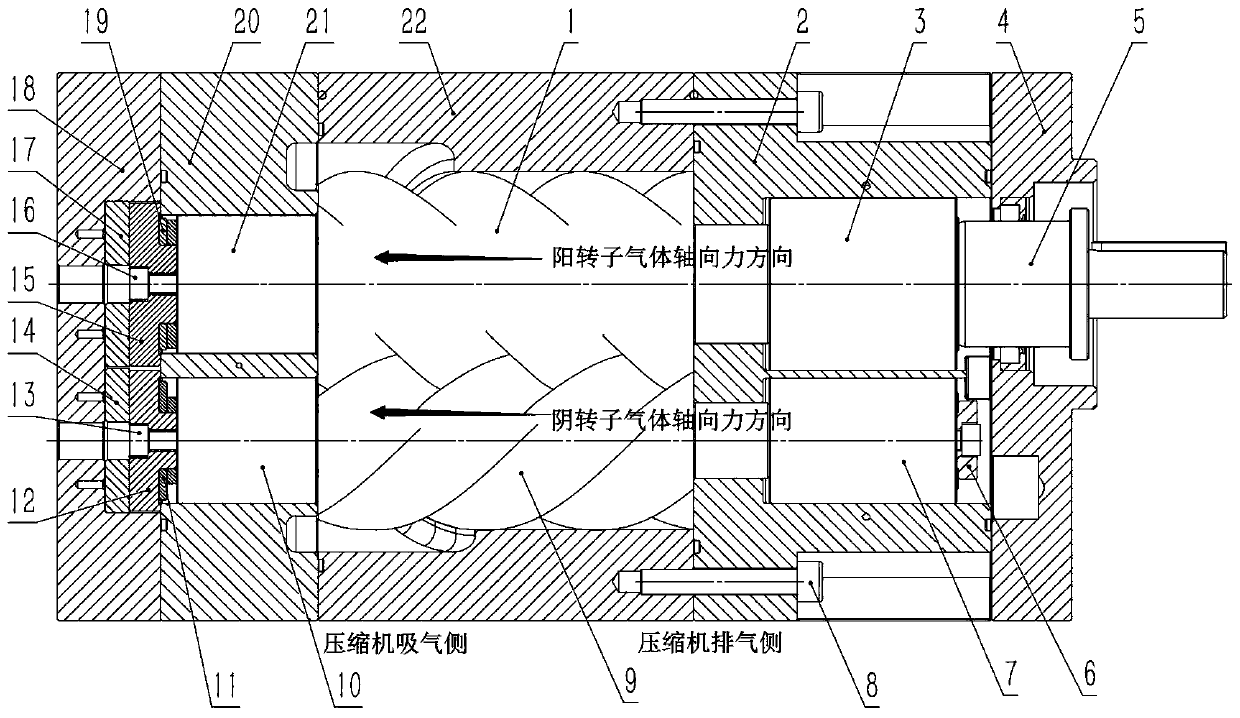

[0017] figure 1 It is a structural diagram of the screw compressor manufactured by the present invention. The shaft seal structure of the present invention is mainly composed of the male rotor dynamic thrust disc 15 on the suction side of the male rotor 1, the male rotor static thrust disc 17 and the female rotor 9 on the suction side. The dynamic thrust plate 12 and the static thrust plate 14 of the female rotor are composed. The thrust sliding bearing composed of the dynamic thrust plate and the static thrust plate is located on the suction side of the compressor. The installation position of the aforementioned thrust sliding bearing is different from that of any existing compressor thrust bearing. the installation location.

[0018] Disassemble the end cover 18 on the suction side, and adjust the axial position of the male rotor 1 in the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com