Mining machine walking meshing system suitable for blocky mineral aggregate

A technology for mining machines and mineral materials, applied in slitting machinery, earthwork drilling, and propulsion, etc., can solve the problems of shortening fault handling time, wear and crush, etc., to shorten fault handling time, improve utilization rate and life, and reduce The effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

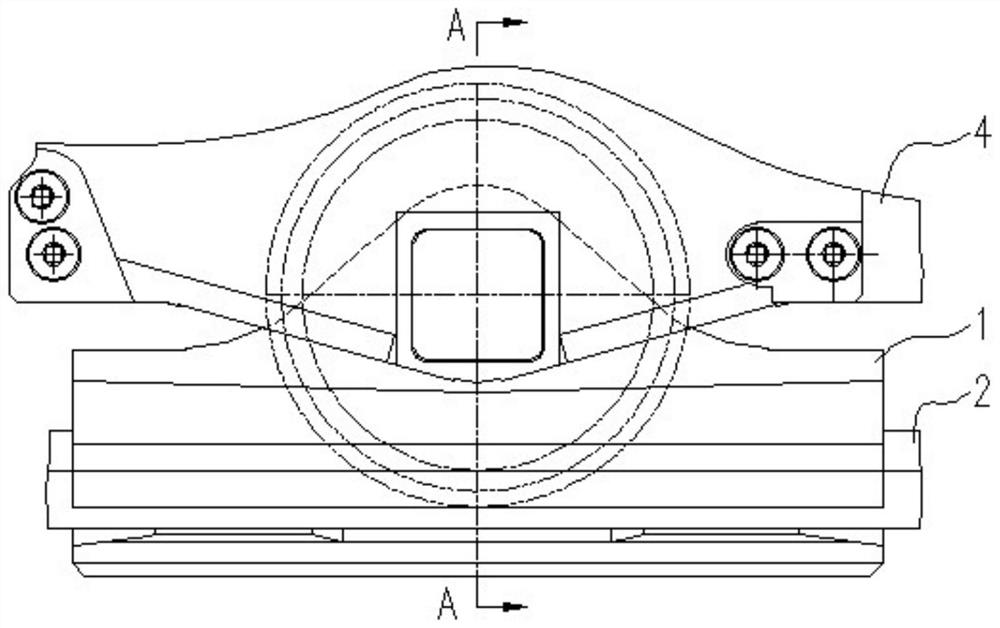

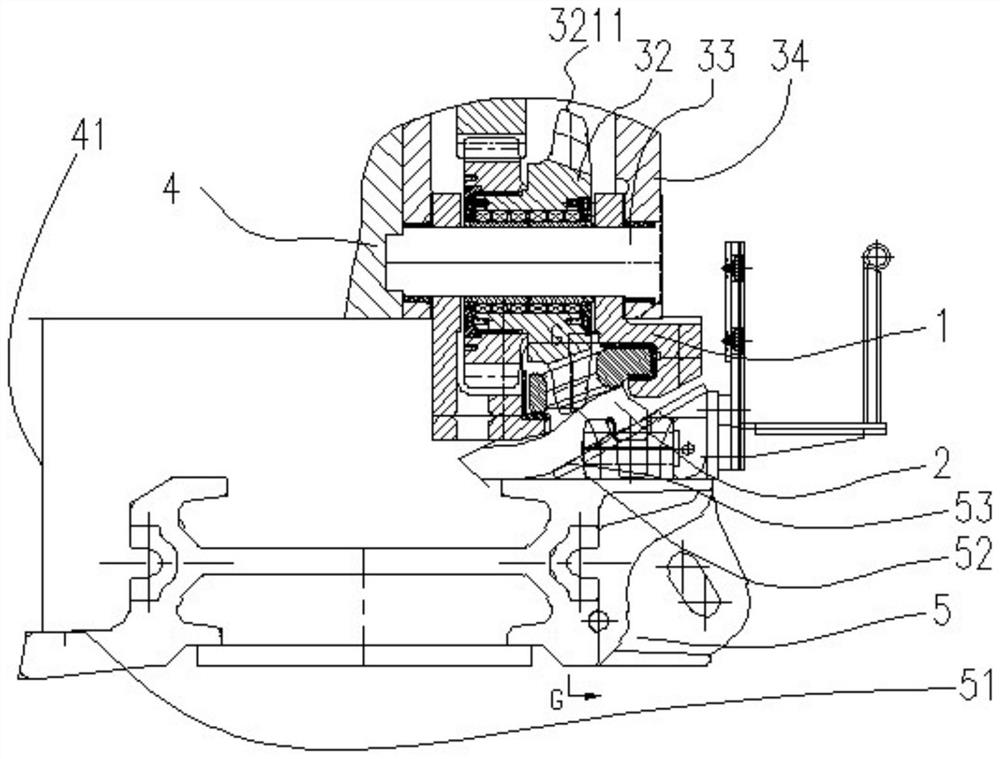

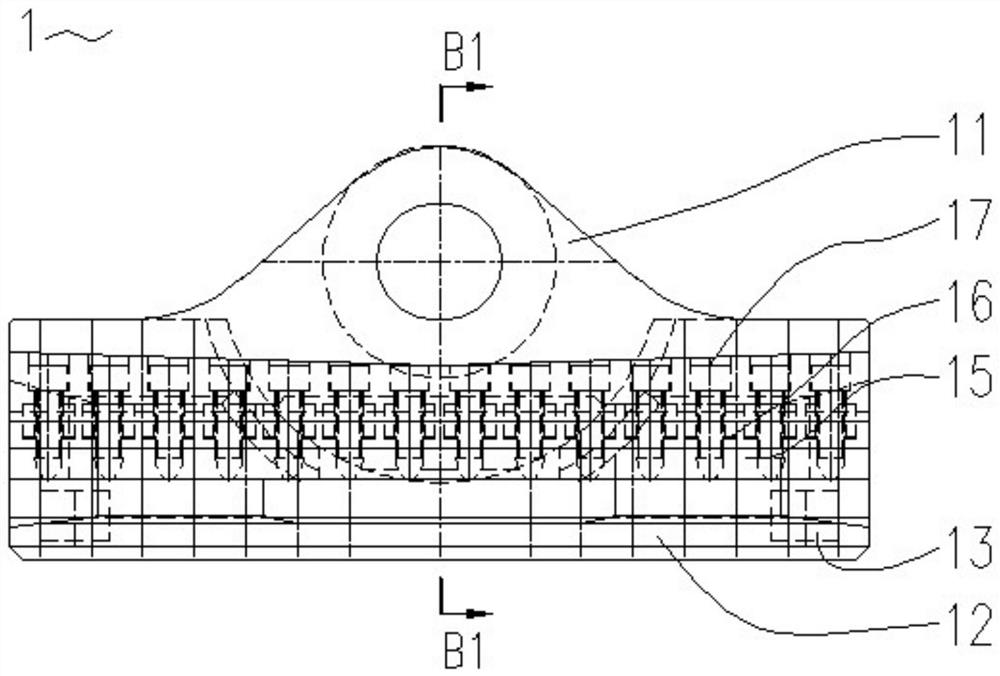

[0045] The invention discloses a walking meshing system of a mining machine (which may be referred to as a walking meshing system) adapted to massive mineral materials, such as Figure 1-15 As shown, it includes a track unit 2 and a guide shoe 1 that straddles the track unit and forms a sliding connection structure with the track unit in the left and right directions. The guide shoe includes a shoe main body 11, a shoe bottom plate 12 and a slider The boot rear plate 15, the bottom plate of the shoe and the rear plate of the shoe are respectively detachably fixedly connected to the bottom of the front part and the bottom of the rear part of the main body of the shoe. The shoe rear plate is used to form the rear bottom hook part of the guide shoe. The front side wear-resistant layer 111 and the rear top wear-resistant layer 113 are arranged on the main body of the skate, the front bottom wear-resistant layer 121 is arranged on the bottom plate of the skate shoe, and the rear si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com