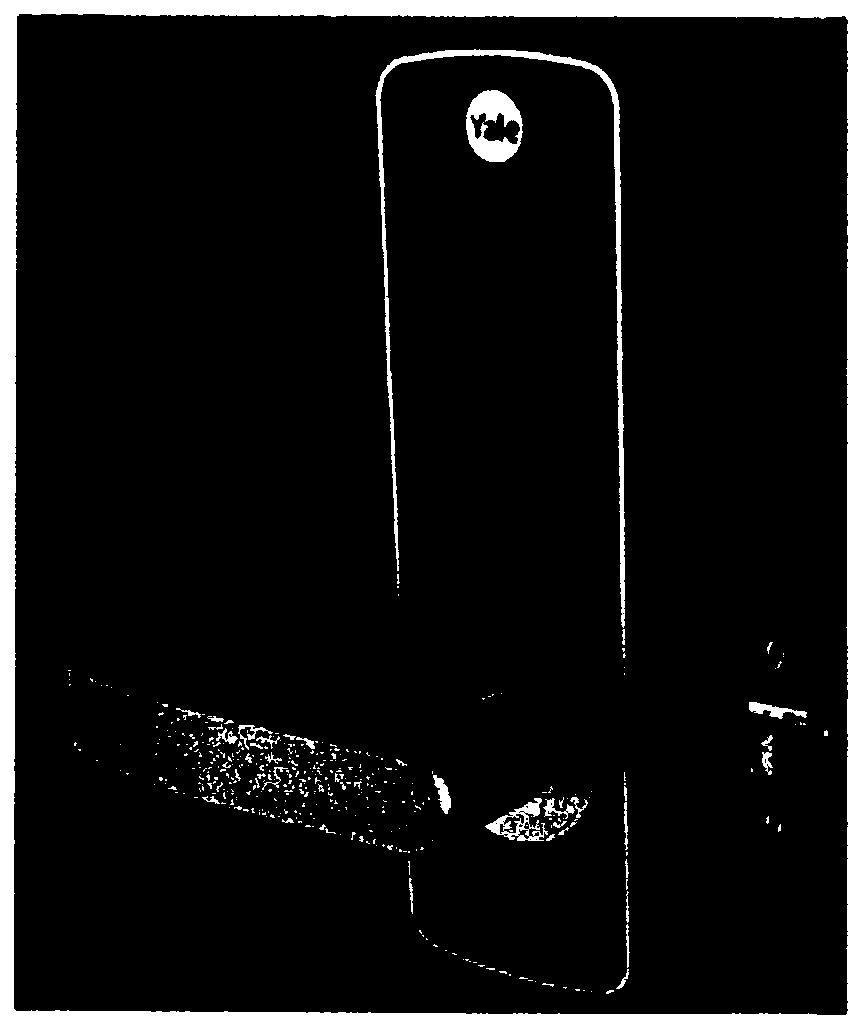

Clutch engagement assembly of door lock and driving device thereof

A technology for joining components and door locks, which is applied in the direction of preventing the key from being removed from the lock, the housing of the lock, door/window accessories, etc., which can solve problems such as incompatibility, reduced versatility, and reduced installation performance, and achieve smoothness Effects of improving operability and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

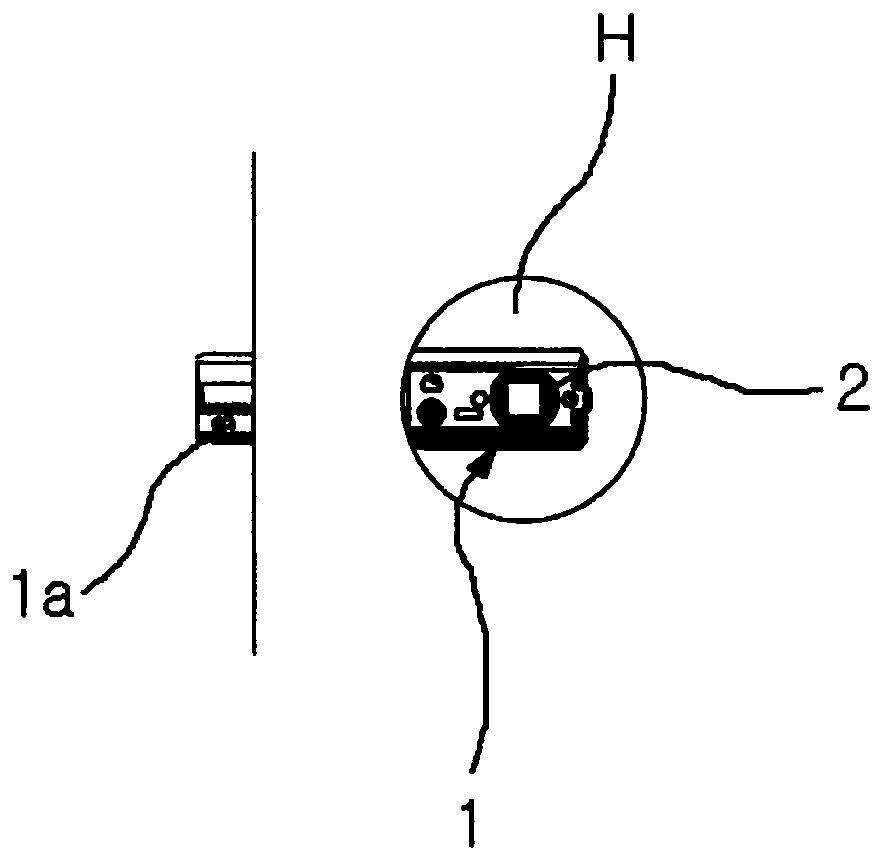

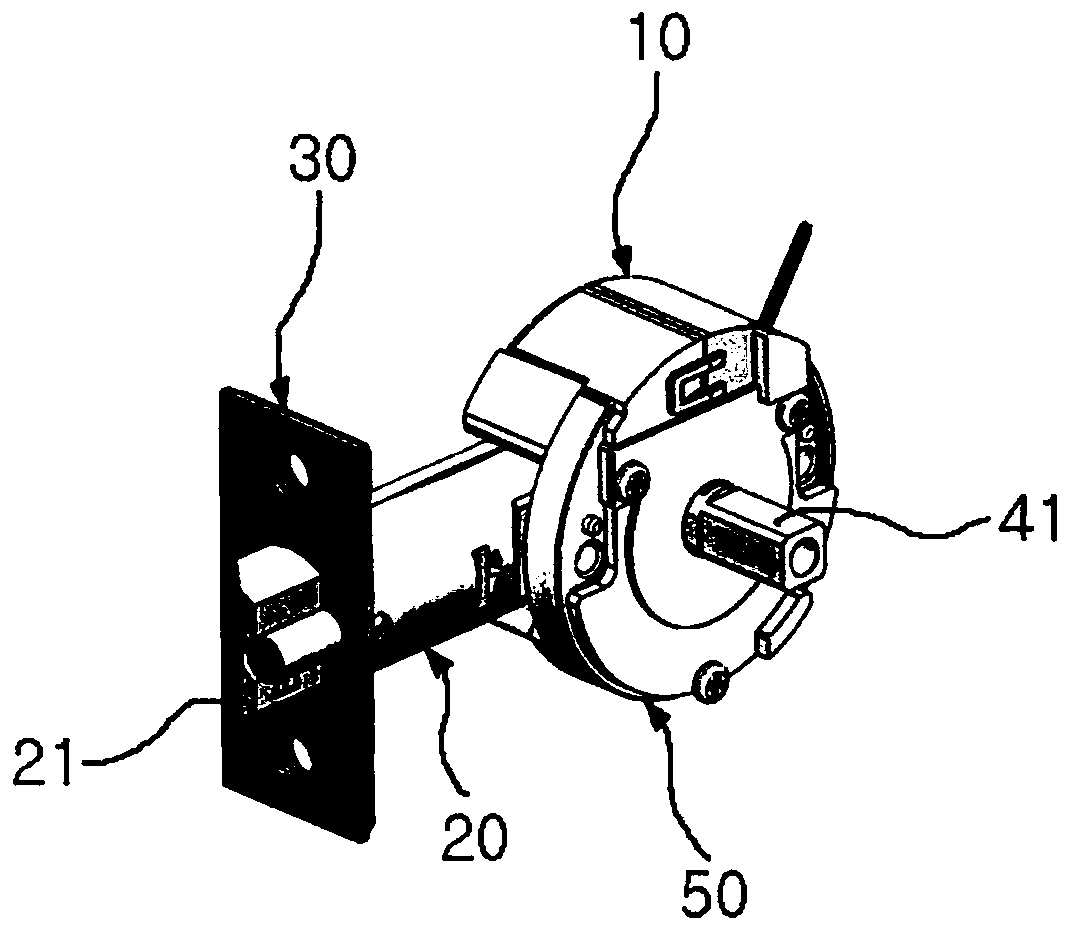

[0049] refer to Figure 2A and 2B , the latch operating body 20 is coupled to the driving module 50 . In the coupled state, the drive mass 50 is formed in the shape of a truncated disk. The motor unit 10 is placed on top of the driving module 50 , and the driving module 50 is generally formed in a disk shape in a state where the motor unit 10 is placed on the driving module 50 . In addition, a placement plate 30 is placed at an end of the latch operation body 20 , and the placement plate 30 is coupled and fixed to a side surface of the door D. As shown in FIG. In addition, the latch operation body 20 includes a latch door bolt 21 at an end thereof.

[0050] The drive module 50 and the motor unit 10 having the above structure are inserted into the circular mounting hole H of the door D by being coupled to each other (see Figure 1B ) to be installed.

[0051] refer to Figures 3A to 3C , the driving module 50 is provided with a pair of support parts 52 extending rearward ...

Embodiment 2

[0081] refer to Figure 15 and 16 , the loading module 50 includes a motor unit 10, a drive plate 60, a first shaft 41, a second shaft 42, and a pin clutch member (not assigned reference numerals).

[0082] The first shaft 41 and the second shaft 42 are installed so as to be arranged on the central axis of the loading module 50 . The motor unit 10 is loaded on an upper portion of the loading module 50 , and the motor unit 10 provides a driving force for rotating the driving plate 60 installed in the loading module 50 .

[0083] The drive plate 60 has an inner curved surface 64 on its inner side. The inner curved surface 64 has an inner cam surface 64a at a part thereof and a circular inner peripheral surface 64b at the other part thereof, wherein the inner cam surface 64a has a curvature smaller than the radius of curvature of the circular inner peripheral surface 64b. radius. An externally toothed gear 61 is formed at a part of the outer circumferential surface of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com