Novel prestressed cable structure based on shape memory alloy

A technology of memory alloy and prestress, which is applied in the direction of cable-stayed bridges, bridge forms, bridge parts, etc., can solve the problems of stress loss and other problems, and achieve the effects of reducing the loss of prestress, good memory performance, and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

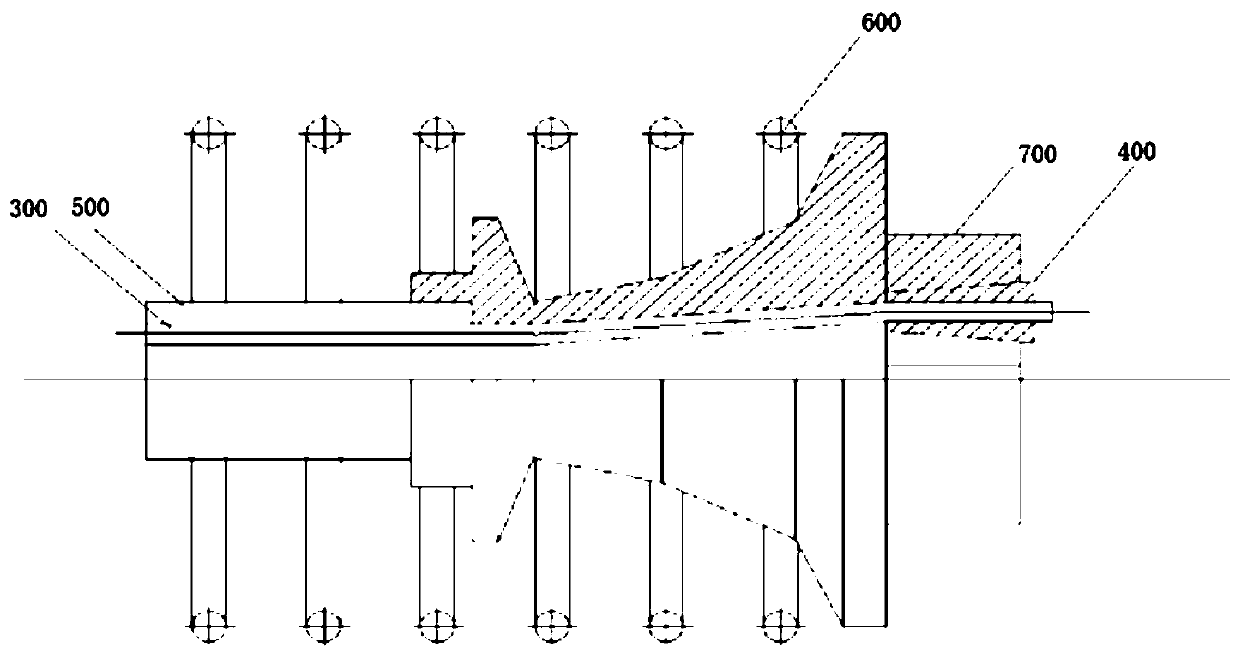

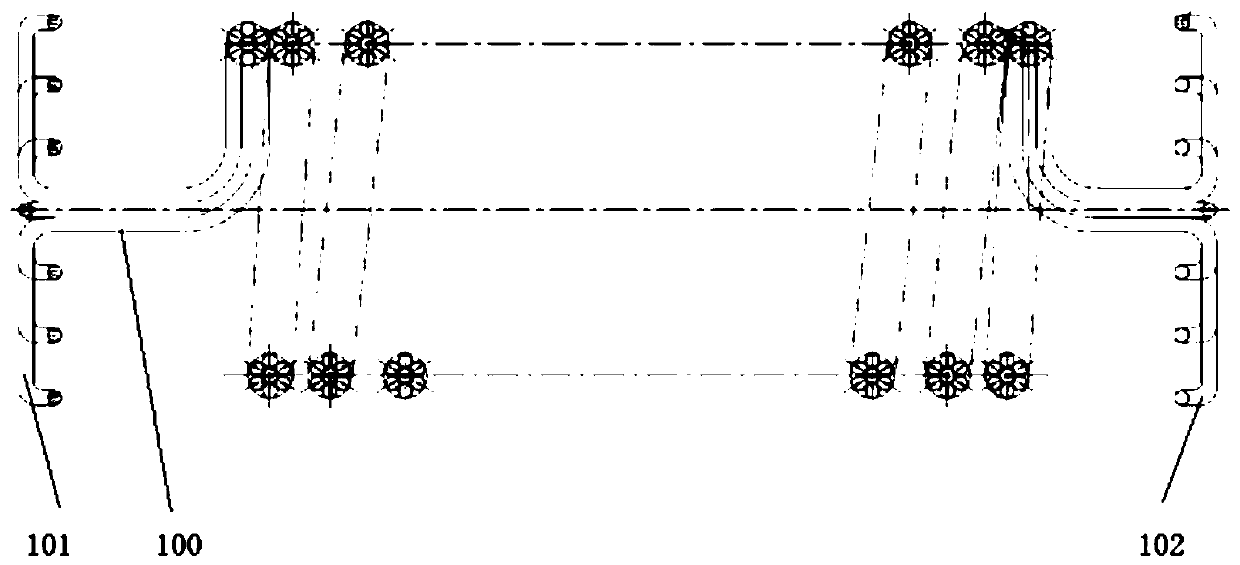

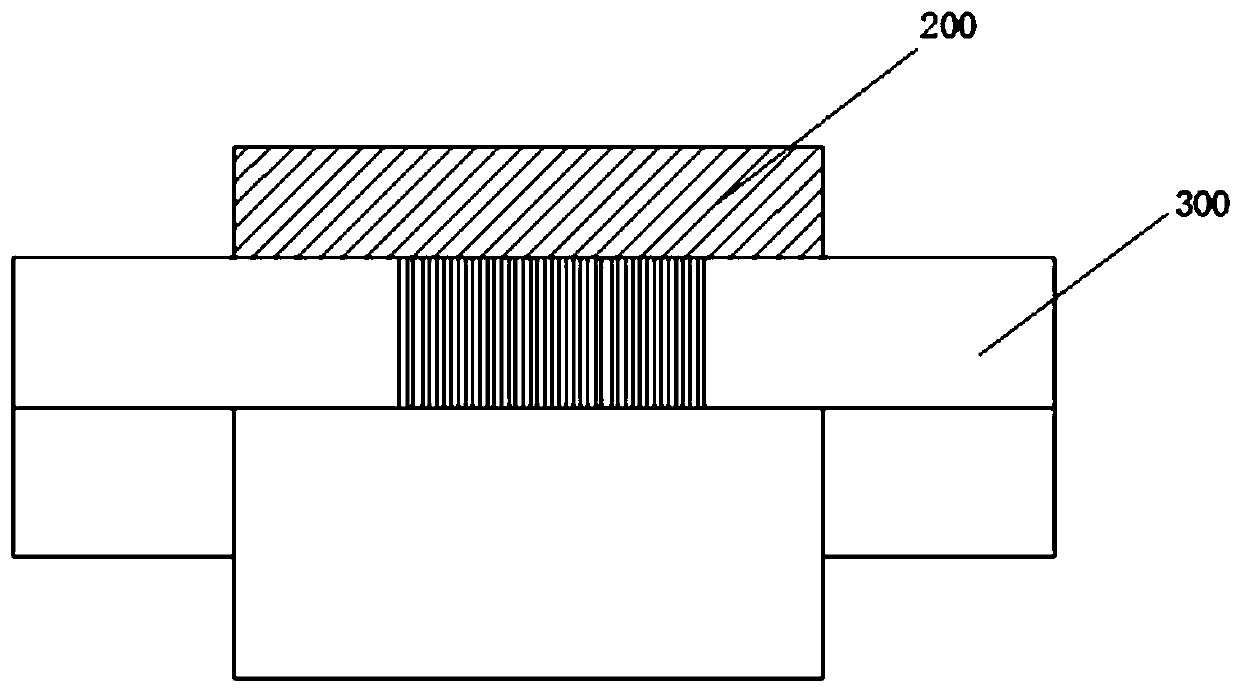

[0027] like Figure 1-4 As shown, the present invention provides a technical solution: a novel prestressed cable structure based on a shape memory alloy, including a shape memory alloy smart anchor cable, and the shape memory alloy smart anchor mainly includes a shape memory alloy helical cable 100 , shape memory alloy pipe joint 200, prestressed rib 300, shape memory alloy clamp 400 and spiral rib 600, the shape memory alloy clamp 400 is mainly composed of shape memory metal anchor clips, and the shape memory metal anchor clips are inserted into the anchor In the hole, the prestressed tendon 300 runs through the shape memory alloy helical cable 100, and the prestressed tendon 300 and the memory alloy helical cable 100 are connected by a shape memory alloy pipe joint 200, and the prestressed tendon 300- There is a bellows 500 on the side, and the spiral rib 600 is composed of multiple sets of shape memory alloy spiral cables 100. The shape memory alloy clamp 400 is used in con...

Embodiment 2

[0031] like Figure 1-4 As shown, the present invention provides a technical solution: a novel prestressed cable structure based on a shape memory alloy, including a shape memory alloy smart anchor cable, and the shape memory alloy smart anchor mainly includes a shape memory alloy helical cable 100 , shape memory alloy pipe joint 200, prestressed rib 300, shape memory alloy clamp 400 and spiral rib 600, the shape memory alloy clamp 400 is mainly composed of shape memory metal anchor clips, and the shape memory metal anchor clips are inserted into the anchor In the hole, the prestressed tendon 300 runs through the shape memory alloy helical cable 100, and the prestressed tendon 300 and the memory alloy helical cable 100 are connected by a shape memory alloy pipe joint 200, and the prestressed tendon 300- There is a bellows 500 on the side, and the spiral rib 600 is composed of multiple sets of shape memory alloy spiral cables 100. The shape memory alloy clamp 400 is used in con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com