Prestressed fibre reinforced steel concrete structure and its prestressed construction method

A technology of concrete structure and reinforced concrete, applied in building structure, construction and other directions, can solve the problems of underutilized plastic properties of steel, poor tensile properties, small spanning ability, etc., to achieve high stiffness, light weight, large The effect of leapfrog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with embodiment, further illustrate the present invention.

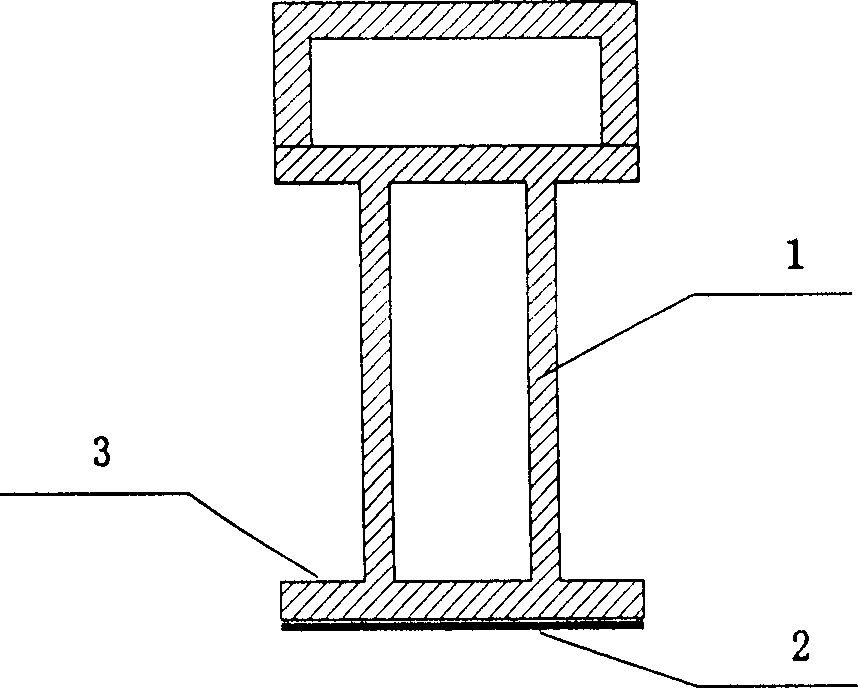

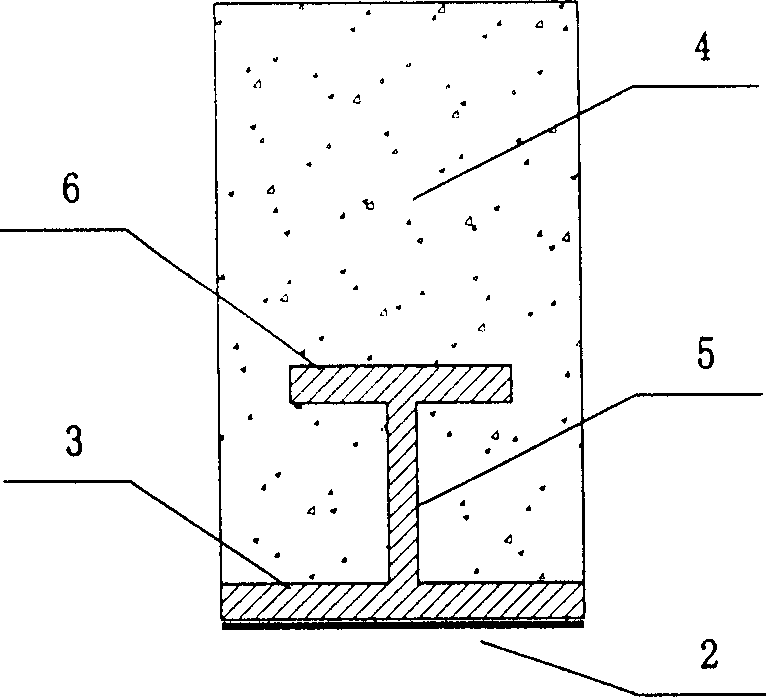

[0034] as attached Figure 6 The shown test beam member adopts a structure formed by welding a channel steel 7 on the upper wing plate 6 of the I-shaped steel 5. The height of the combined structure is 140 mm, and the width of the lower wing plate 3 is 68 mm. The width of the channel steel 7 is 63mm, and the length of the test beam is 2m. The construction steps of pre-bending and pre-stressing technology of reverse loading and then forward loading of the test beam:

[0035] 1. Reverse loading prebending prestressing construction steps:

[0036] In order to facilitate the loading and pasting of carbon fiber cloth, the test beam member was turned over 180 degrees, and a single-point loading scheme was adopted.

[0037] ① Reversely load the section steel composite structure so that the lower flange 3 is under tension and reaches 0.9 times the yield strain of the steel, and the load is sust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com