A new energy vehicle torsion bar spring suspension surface laser heat treatment device

A laser heat treatment, new energy vehicle technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of weakened fatigue resistance, easy bending of torsion bars, uneven hardness, etc., and achieve the effect of increasing the degree of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

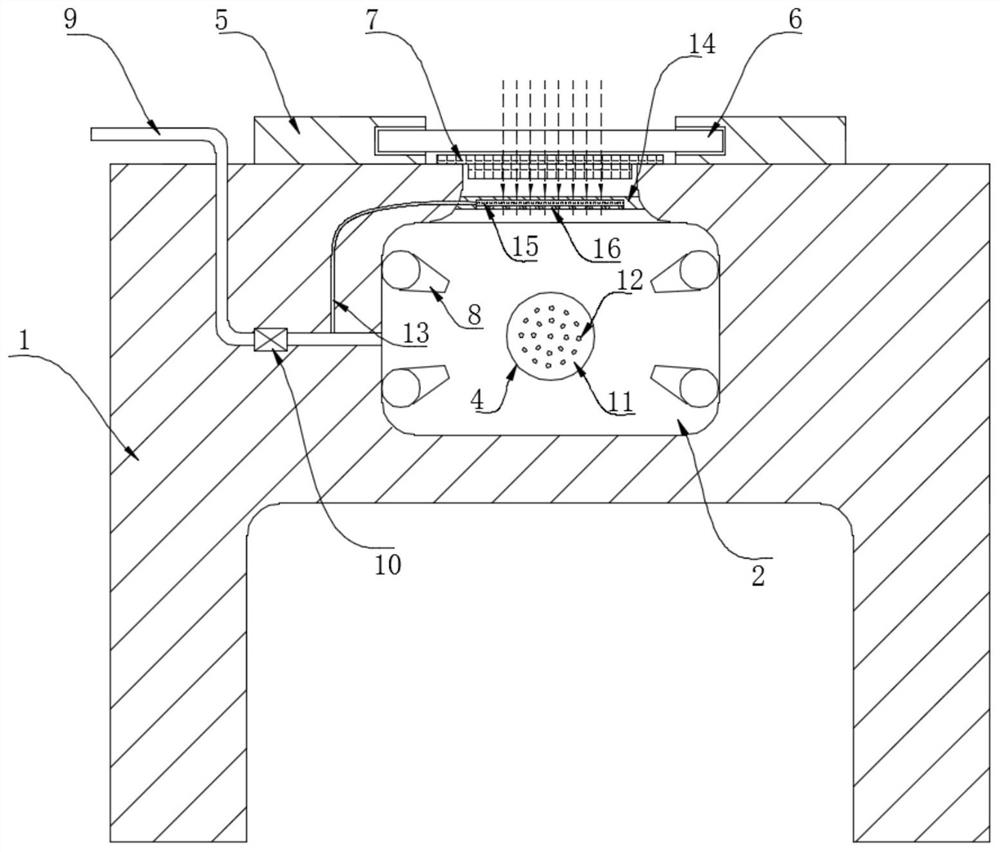

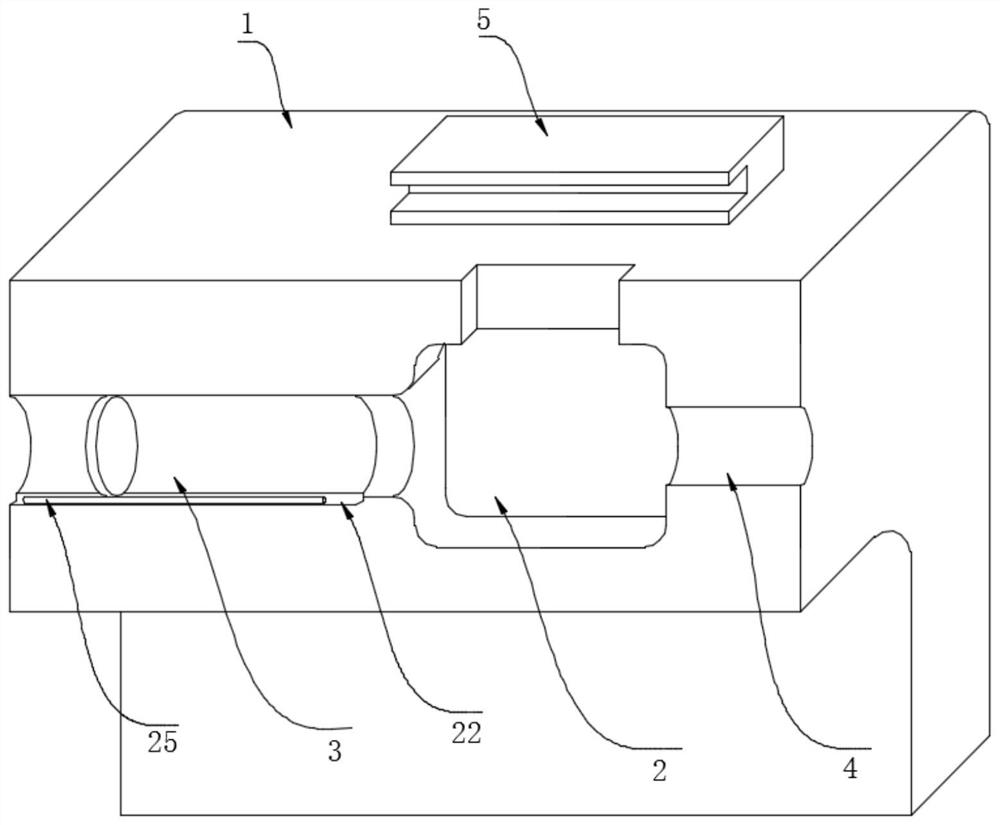

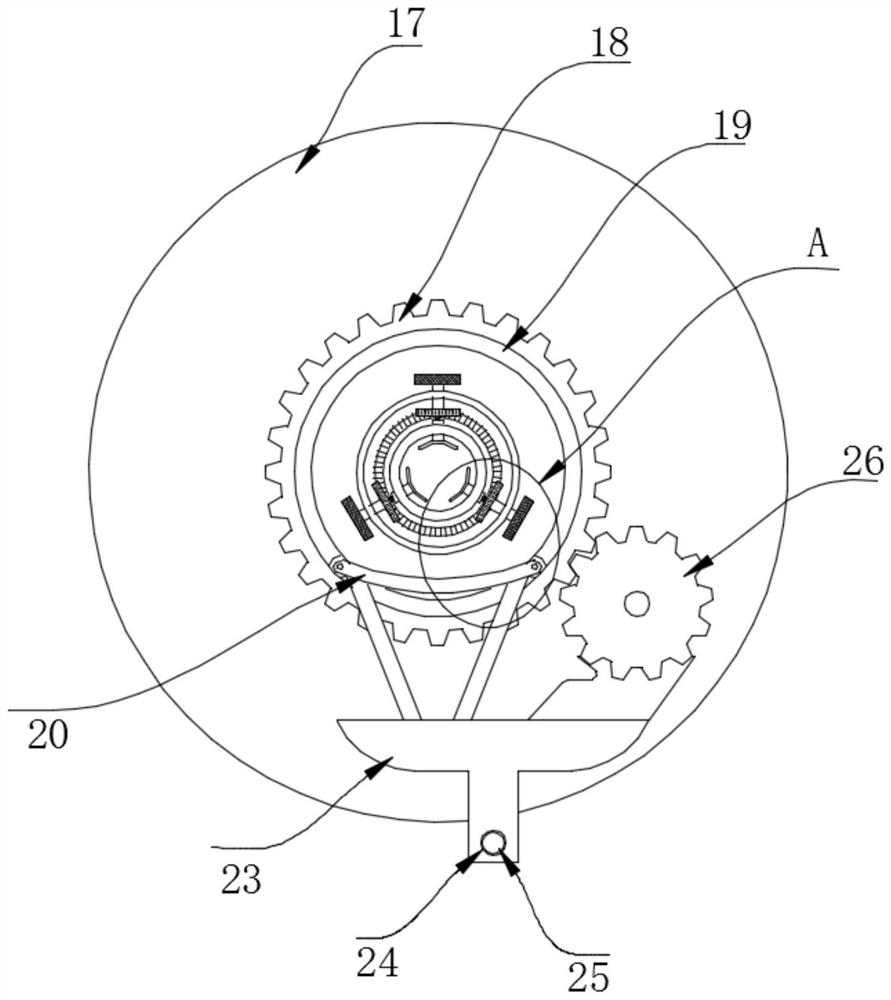

[0024] refer to Figure 1-4 , a new energy vehicle torsion bar spring suspension surface laser heat treatment device, including a reaction frame 1, a reaction chamber 2 is opened in the reaction frame 1, the reaction chamber 2 communicates upward with the outside world, and the front and rear ends of the reaction chamber 2 are respectively provided with a The clamping chamber 3 and the constant pressure chamber 4 connected with it, the upper top of the reaction frame 1 are welded with two positioning plates 5, and one end of the two positioning plates 5 close to each other is provided with a card slot, and the two card slots are jointly locked. A laser plate 6 capable of emitting laser light is connected. The laser plate 6 is located directly above the reaction chamber 2. A photodetection plate 7 is fixed at the upper interface between the reaction chamber 2 and the outside world. The inner wall of the reaction chamber 2 is fixedly connected with multiple pointing reaction plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com