Nitrogen sealing system of tank field

A technology of nitrogen blanketing and tank farms, applied in the field of nitrogen blanketing system, can solve the problems of increased energy consumption in system operation, increased investment in pipeline accessories, unbalanced nitrogen consumption, etc., and achieves the reduction of total emissions, the reduction of the scale of air separation units, and the reduction of nitrogen The effect of decreasing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

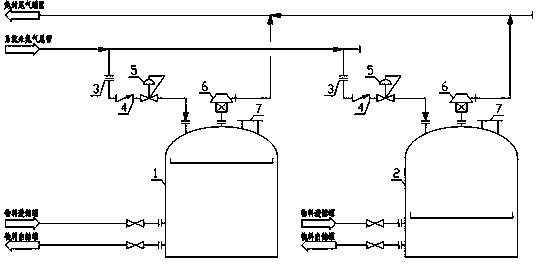

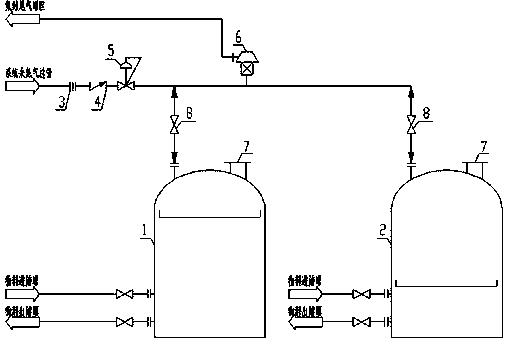

[0012] System design description: figure 1 and figure 2 The storage tanks (1, 2) are used as examples in the middle, and more storage tanks can be added when the system is set up. The relationship is similar to the attached figure.

[0013] figure 1 and figure 2 The middle restrictor orifice 3 is a nitrogen flow control element, which can effectively prevent the overpressure of the storage tank from being released due to excessive nitrogen replenishment, resulting in nitrogen waste.

[0014] figure 1 and figure 2 The stop return valve 4 can effectively prevent the flammable gas from running back to the nitrogen gas filter and prevent the occurrence of explosion accidents.

[0015] figure 1 and figure 2 Medium self-operated nitrogen sealing valve 5, the control tank pressure is stable at +800 ~ +1400kpa, when the pressure drops to +500kpa, the self-operated nitrogen sealing valve opens, and when the pressure increases +1600kpa, the self-operated nitrogen sealing val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com