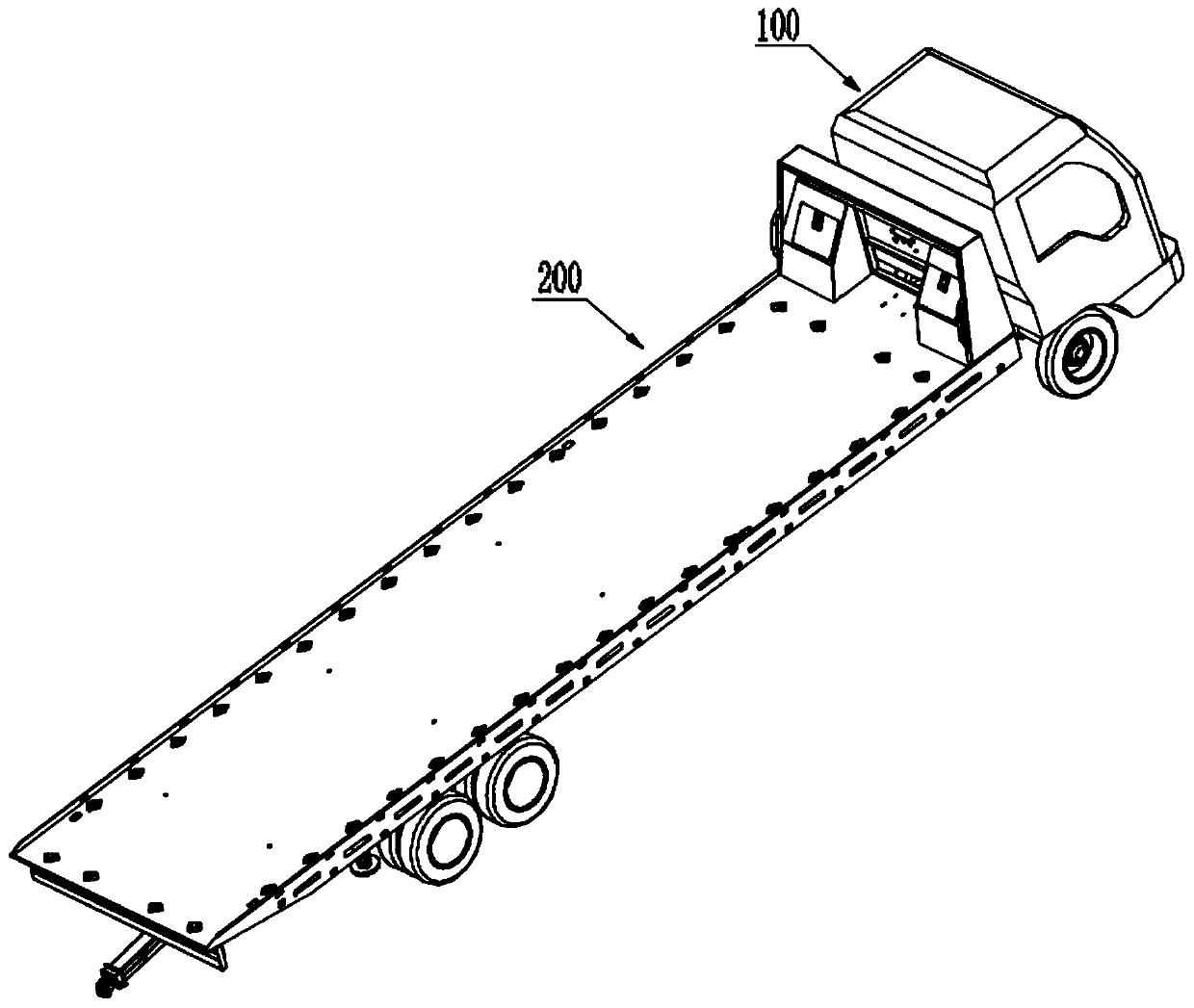

Multifunctional heavy-duty flat-plate wrecker capable of towing three vehicles at a time

A wrecker, multi-functional technology, applied in the direction of motor vehicles, vehicle parts, goods transport vehicles, etc., can solve the problems of unable to meet the heavy load synchronous lifting plate, unable to install, difficult to weld professionally, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further explain how the present invention is implemented in conjunction with the accompanying drawings and specific implementation methods.

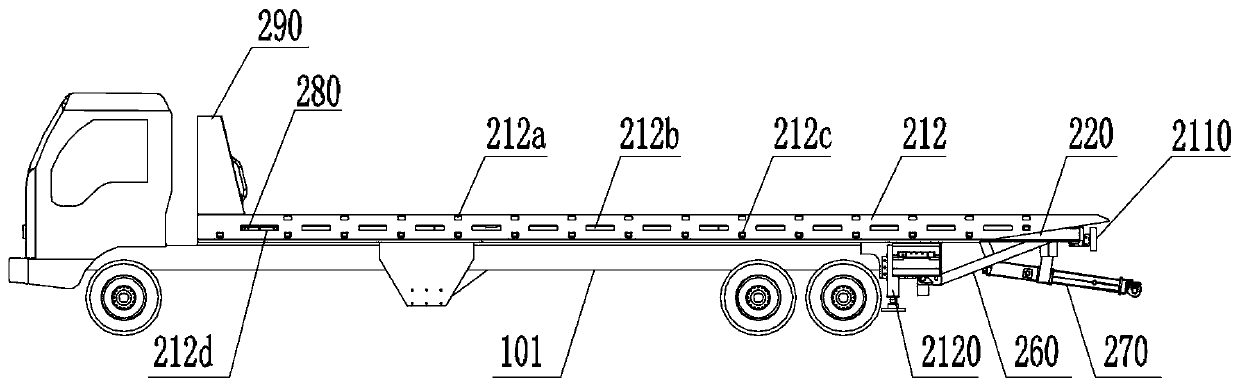

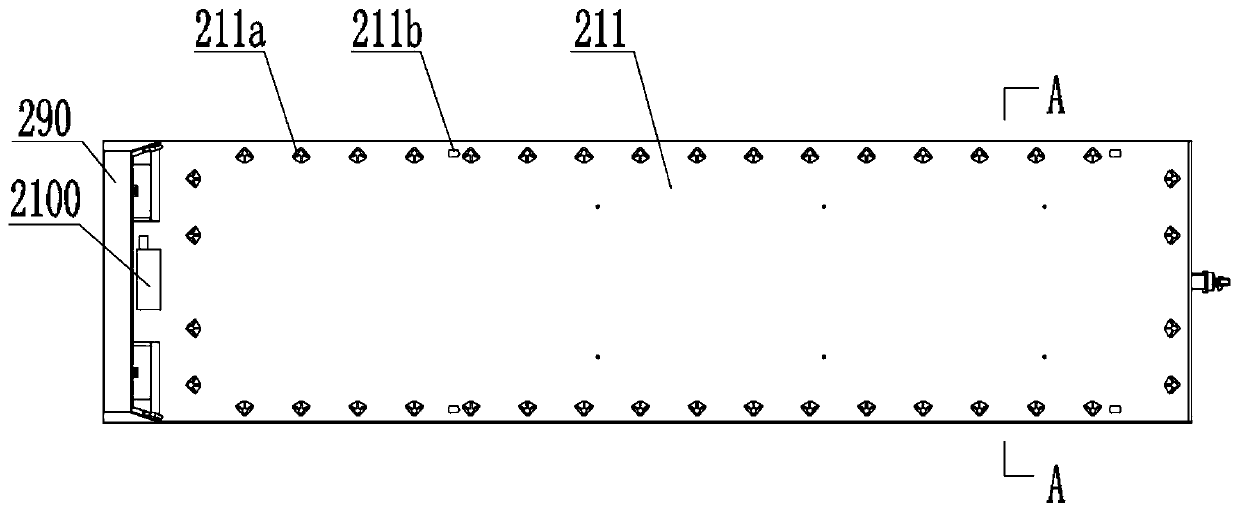

[0067] A kind of one tow three multifunctional heavy-duty flat wreckers provided by the present invention, see for example Figure 1 to Figure 21 As shown, it includes a car chassis 100 and a wrecker top 200 assembled on the car chassis 100; wherein, the wrecker top 200 includes a wrecker flat panel 210, a subframe 220, a double-layer frame 230, and a flat tilting oil cylinder 240 , flat telescopic oil cylinder 250, triangular overturning mechanism 260, towing device 270, suspended ladder 280, gantry toolbox 290, hydraulic winch reel 2100, rotatable tail light frame 2110 and hydraulic outrigger 2120; wrecker flatbed 210 is arranged on the upper part of the subframe 220, the subframe 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com