Air curtain cleaning mechanism for printing equipment

A technology of printing equipment and air curtain, which is applied in the field of air curtain cleaning mechanism of printing equipment, and can solve problems such as unevenness, excessive brush dragging force, and surface damage of printed matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

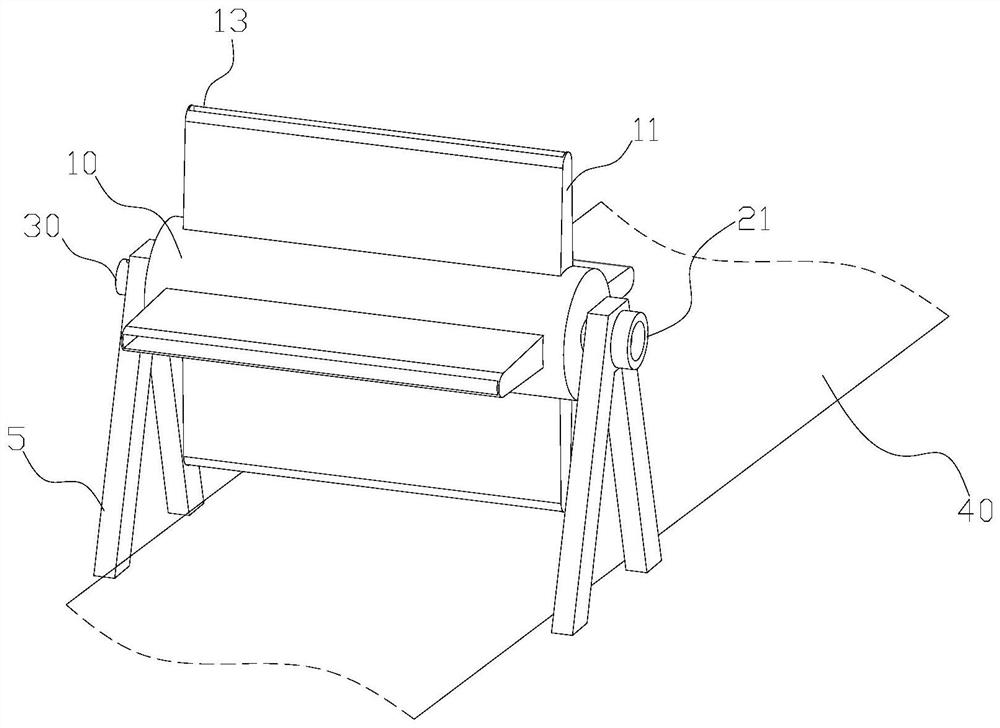

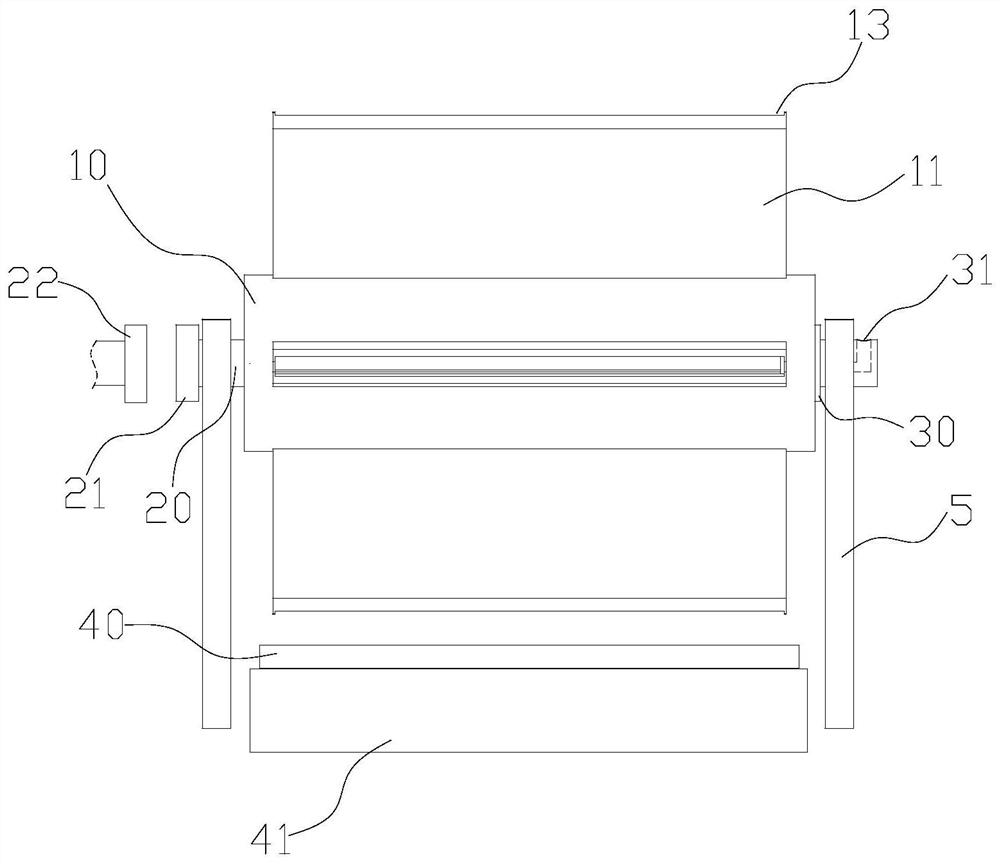

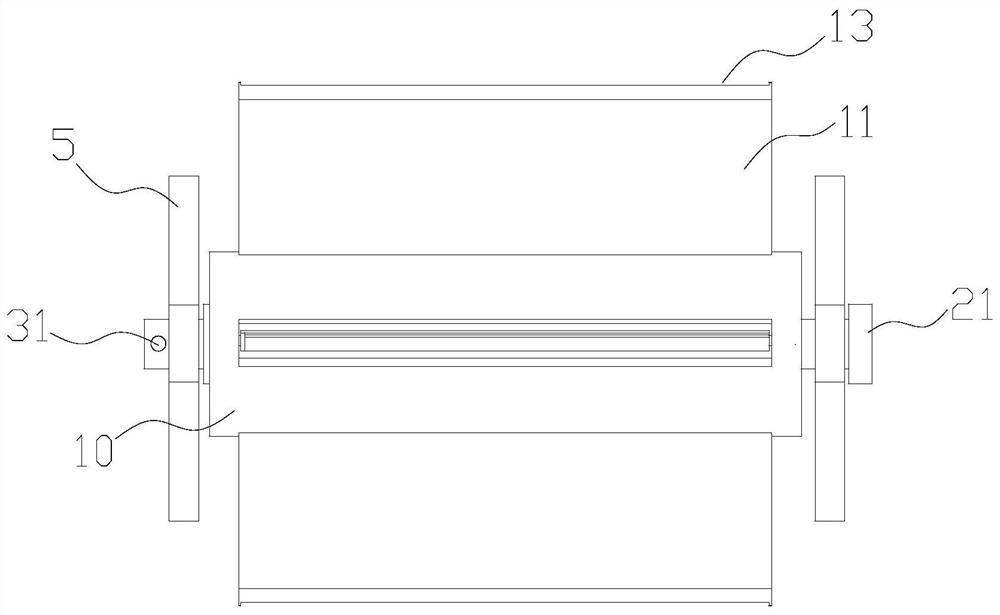

[0029] Such as Figure 1-7 As shown, an air curtain cleaning mechanism for printing equipment according to the present invention is used to clean the surface of the intermediate finished product 40 of the uncut printed matter, and the purpose is to remove some solid residues 6 remaining on the surface of the printed matter. The residue 6 may be some waste slag, debris, particles of solidified ink droplets, dust and the like. It needs to be cleared in time before it can be transported to the subsequent station for cutting.

[0030] Air curtain cleaning mechanism of printing equipment, including but not limited to: supporting mechanism and blowing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com