Forming method for J-shaped composite material rib

A composite material and molding method technology, applied in the field of automatic manufacturing and processing of composite rib parts, can solve problems such as deformation, affecting the quality of parts bonding, and inability to automatically manufacture and produce composite rib parts, so as to ensure quality and realize Automated manufacturing, solving the effect of easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

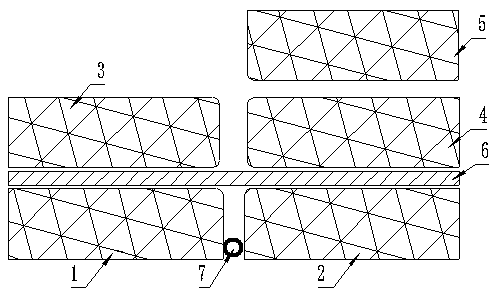

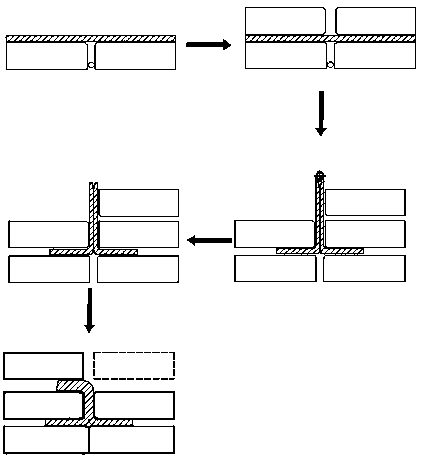

[0023] See figure 1 , the part has three bends, the bottom is a left-right symmetric bend, and the top is a side-facing bend. A molding method of a J-shaped composite rib of the present invention is formed through the following steps:

[0024] Step 1, laying the prepreg sheet on the bending mold;

[0025] Step 2: Bending the prepreg sheet into the shape of "Ji" through mechanical traction;

[0026] Step 3: Cut the top of the prepreg bent into the shape of "ji" to make it into the shape of "er";

[0027] Step 4, the left and right pressing blocks of the middle layer of the mold move to the middle, compacting the prepreg into a "T" shape;

[0028] Step 5: Bending the "T" shaped prepreg into a "J" shape through the translation of the pressing block on the upper layer of the mold.

Embodiment 2

[0030] The molding method of " J " shape composite rib parts of the present invention, the steps are:

[0031] Step 1, laying the prepreg sheet 6 on the lower left press block 1 and the lower right press block 2 of the bending mold;

[0032] Step 2, combining the left middle laminated block 3 and the right middle laminated block 4 on the mold, and compacting the prepreg sheet 6;

[0033] Step 3, the prepreg sheet 6 is bent into the shape of "几" through the traction of the traction bar 7;

[0034] Step 4, cut the top of the prepreg 6 bent into the shape of "ji" to make it into the shape of "er";

[0035] Step 5: Remove the drawbar 7, and move the lower left press block 1, lower right press block 2, middle left laminate block 3, and middle right laminate block 4 on the mold to the middle at the same time, and compact the prepreg 6 into a "T" shape;

[0036] Step six, the translational upper laminate block 5 on the mold is translated, and the "T" shaped prepreg 6 is bent into ...

Embodiment 3

[0038] The bending forming mold of the present invention comprises a left lower pressing block 1, a right lower pressing block 2, a left middle pressing block 3, a right middle pressing block 4 and an upper pressing block 5, and each of the five pressing blocks can relatively independently move. The 5 pressing blocks of the bending forming mold can independently provide pressure in the up and down, left and right directions. The pressing blocks of the bending forming mold are all chamfered on the corners in contact with the prepreg. The chamfer value is determined from the design value of the "J" shaped rib part.

[0039] In the present invention, the pressing block in the bending mold is made of metal material, but the use of other materials is not limited.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com