Polishing device for sheet metal parts

A polishing device and a technology for sheet metal parts, applied in the field of sheet metal parts, can solve the problems of poor polishing effect, poor debris and dust treatment, etc., and achieve the effect of improving convenience, convenient centralized processing, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

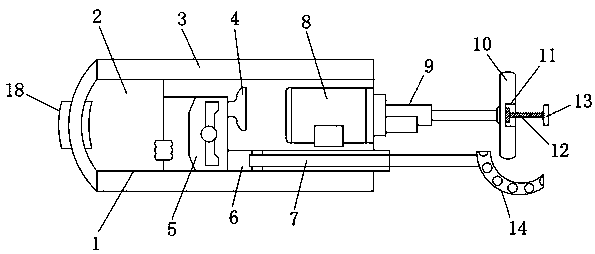

[0020] Such as figure 1 As shown, a polishing device for sheet metal parts includes a handle 1, a motor 8 is clamped at one end of the handle 1, an electric cylinder 9 is installed at one end of the handle 1, the output shaft of the motor 8 is clamped with the electric cylinder 9, and one end of the electric cylinder 9 A polishing disc 10 is clamped, and the interior of the polishing disc 10 is inlaid with a groove 11, and the inner wall of the groove 11 is inlaid with an air pressure rod 12. One end of the air pressure rod 12 is fixedly connected to the small hole polishing disc 13, and the connecting pipe 6 is located at the bottom of the handle 1 to collect dust. Both the chamber 2 and the suction port 4 are located inside the handle 1, and a valve 18 is installed on one side of the dust collection chamber 2.

[0021] In this embodiment, by setting electric cylinder 9, air pressure rod 12 and small hole polishing disc 13, it is convenient for people to polish small sheet me...

Embodiment 2

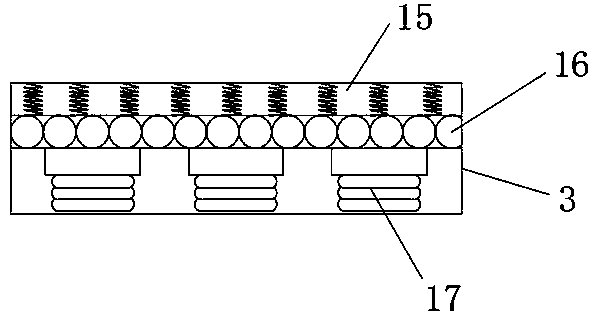

[0023] Such as Figure 1-2 As shown, a small exhaust fan 5 is installed at one end inside the handle 1, one side of the small exhaust fan 5 is fixedly connected to the dust collection chamber 2, and the other end of the small exhaust fan 5 is installed with an air suction port 4 and a connecting pipe 6, and the connecting pipe 6 is internally slidably connected Sleeve pipe 7, one end of socket pipe 7 is welded with arc-shaped suction pipe 14, which is located on one side of polishing disc 10, rubber shock-absorbing pad 3 is sleeved on the outside of handle 1, and the inside of rubber shock-absorbing pad 3 is filled with The spring layer 15, the elastic ball layer 16 and the air cushion shock absorber 17, the elastic ball layer 16 is bonded to the bottom of the spring layer 15, and the air cushion shock absorber 17 is bonded to the bottom of the elastic ball layer 16.

[0024] In this embodiment, by arranging a small exhaust fan 5, a connecting pipe 6, a socket pipe 7 and an ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com