Control analysis method based on improved FMEA

A control analysis and technology to be analyzed, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of inaccurate risk assessment, poor reliability of result analysis, and limit the application of intelligent manufacturing technology, so as to improve the accuracy The effect of degree and clear classification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Below in conjunction with accompanying drawing, the present invention will be further described:

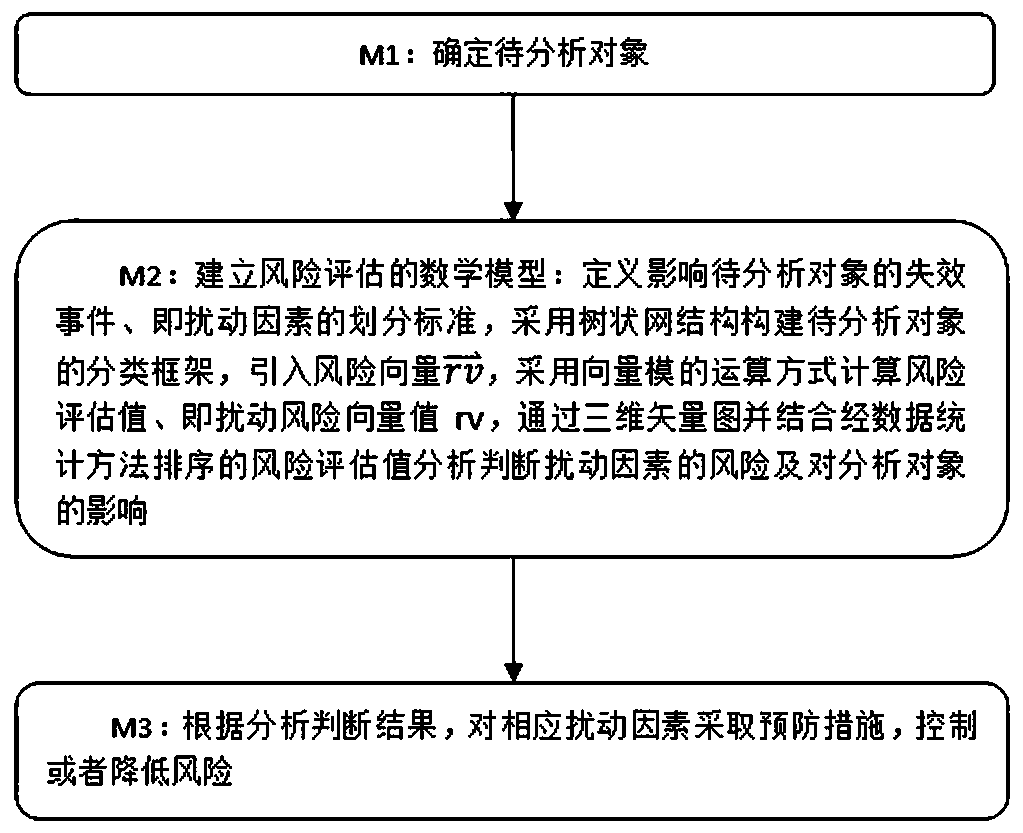

[0058] Such as figure 1 Shown, the present invention provides a kind of control analysis method based on improved FMEA, and it comprises the following steps:

[0059] M1: Determine the object to be analyzed.

[0060] M2: Establish a mathematical model for risk assessment: define the failure events that affect the object to be analyzed, that is, the division standard of disturbance factors, build a classification framework for the object to be analyzed, and analyze and judge the risk of disturbance factors;

[0061] The mathematical model of risk assessment in M2 is a vector mathematical model, which specifically includes the following steps:

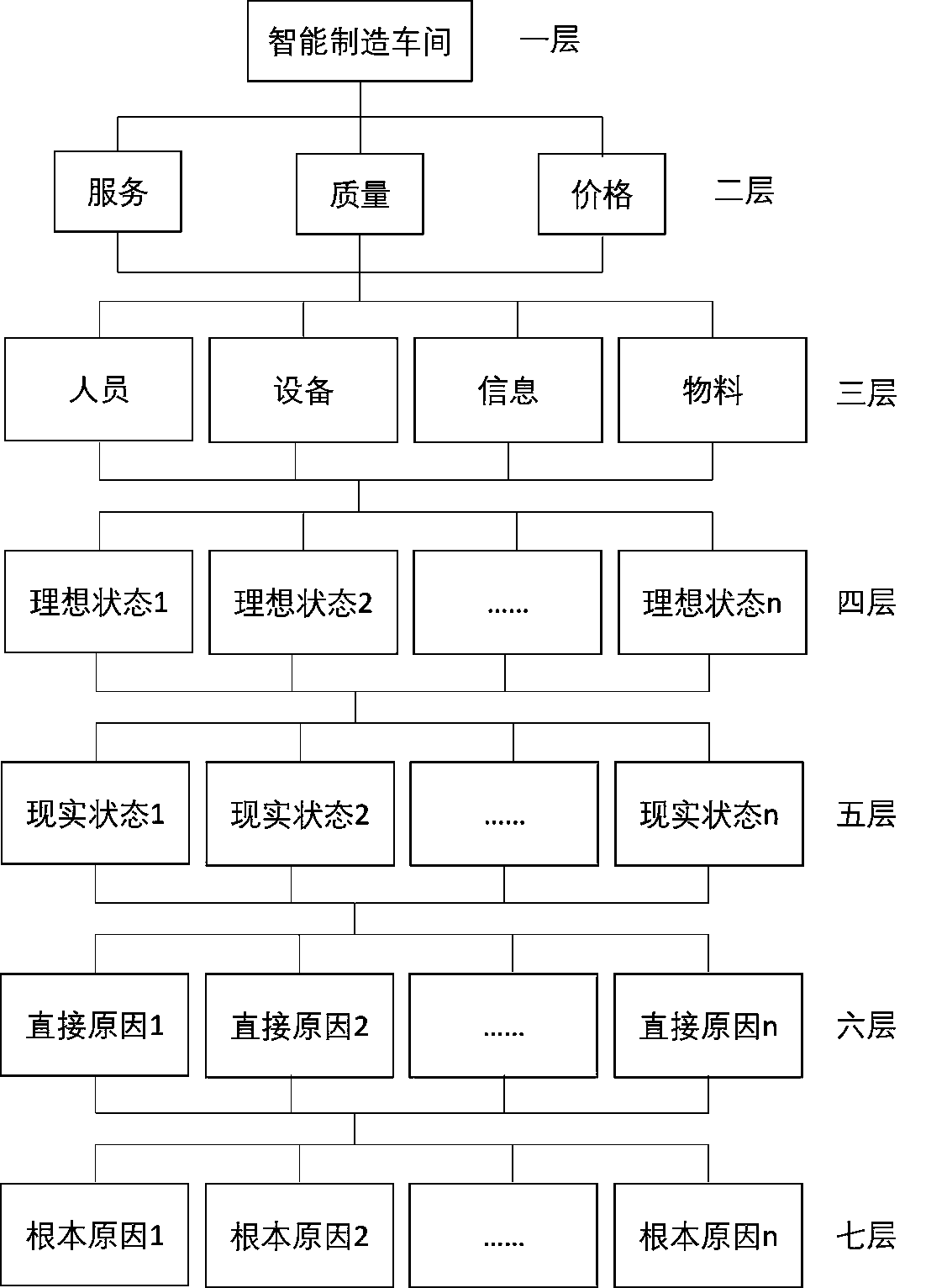

[0062] M2.1: Divide the disturbance factors of the object to be analyzed into at least two layers, and each layer has at least two disturbance factors, construct the classification framework of the object to be analyzed with a tree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com