Lubricating oil viscosity detecting device

A detection device and lubricating oil technology, which is applied to measuring devices, flow characteristics, instruments, etc., can solve the problems of inability to offset impact force, inconvenient detection of lubricating oil viscosity, inability to detect lubricating oil viscosity, etc., and achieve accurate and effective detection results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

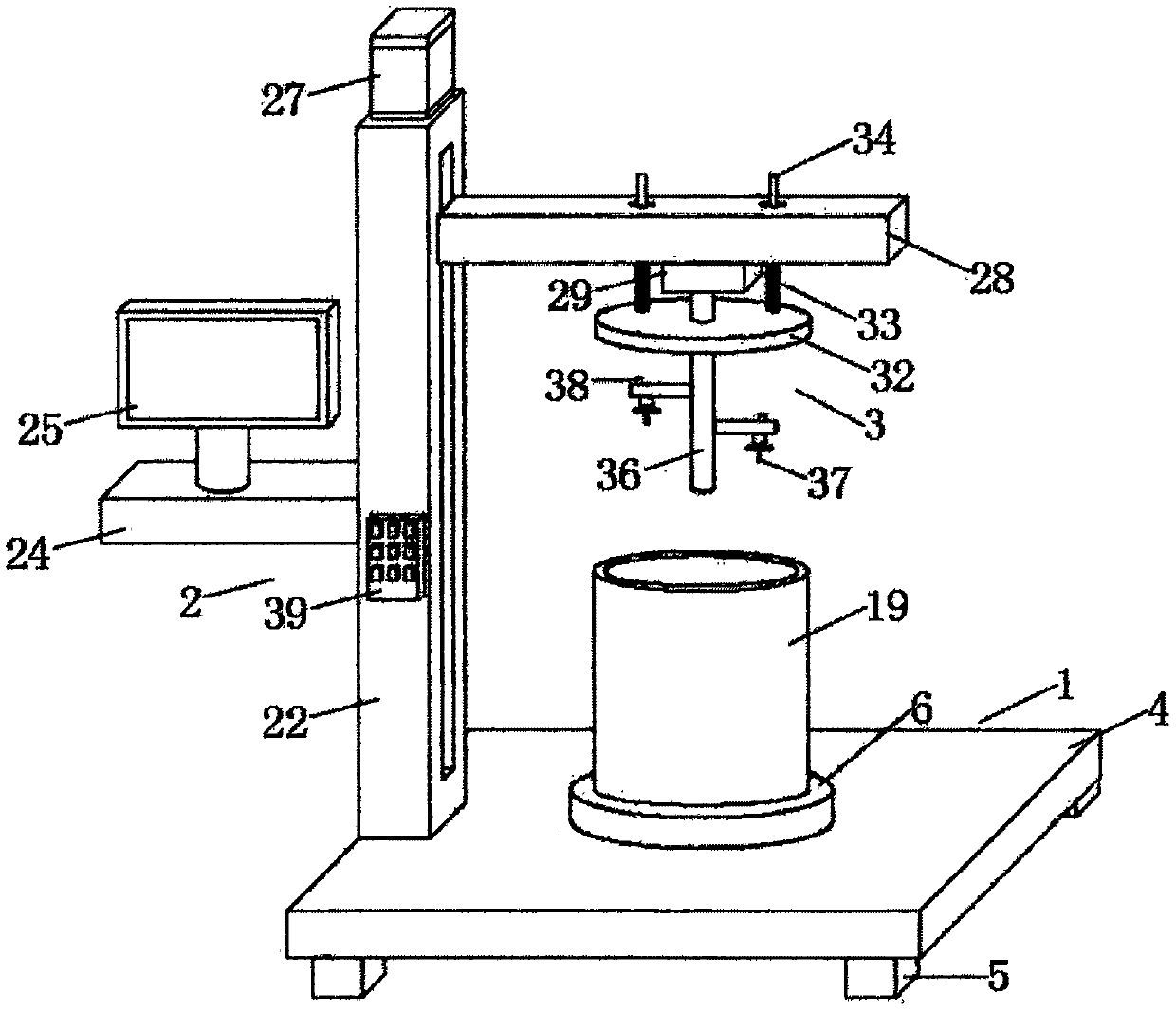

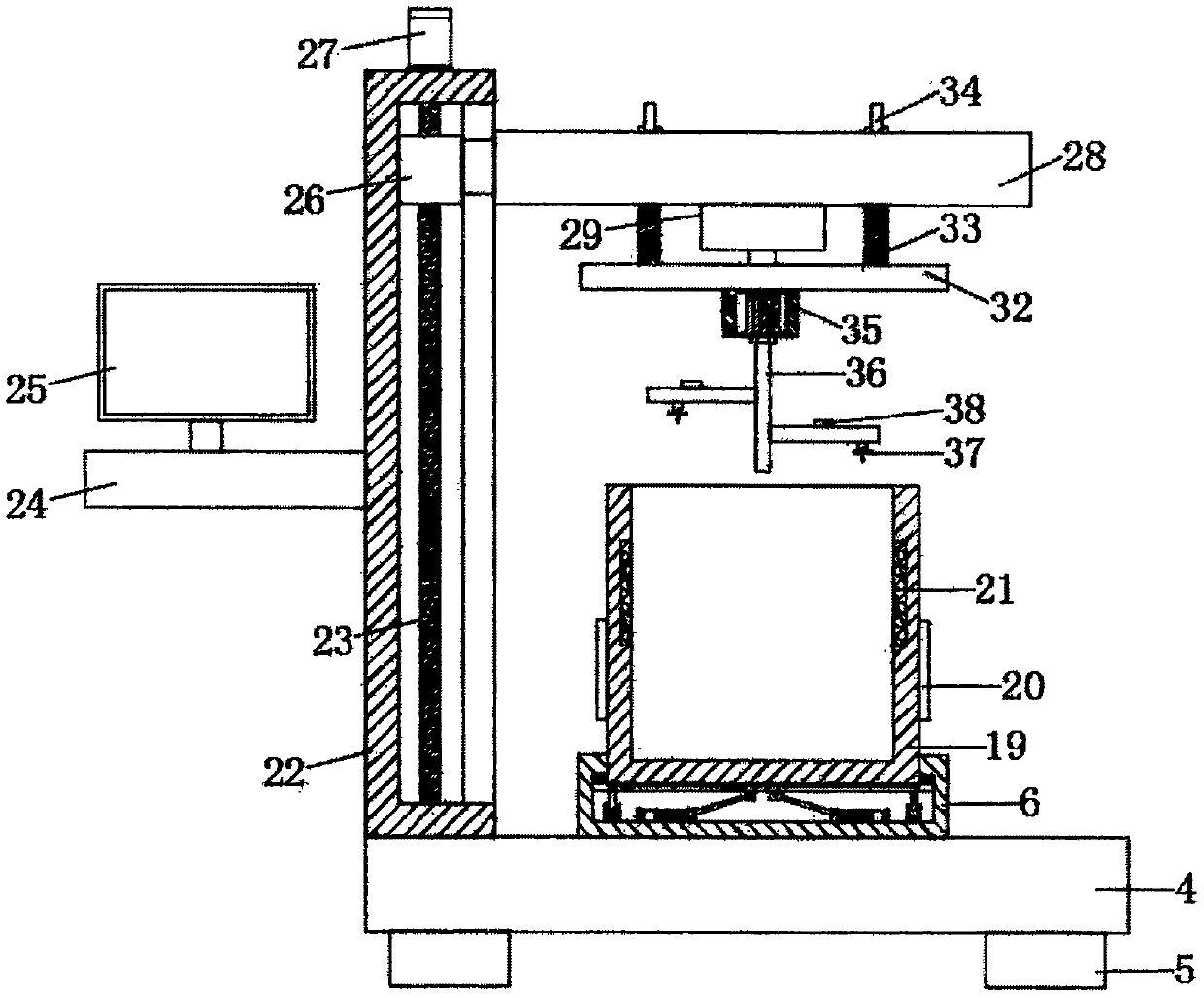

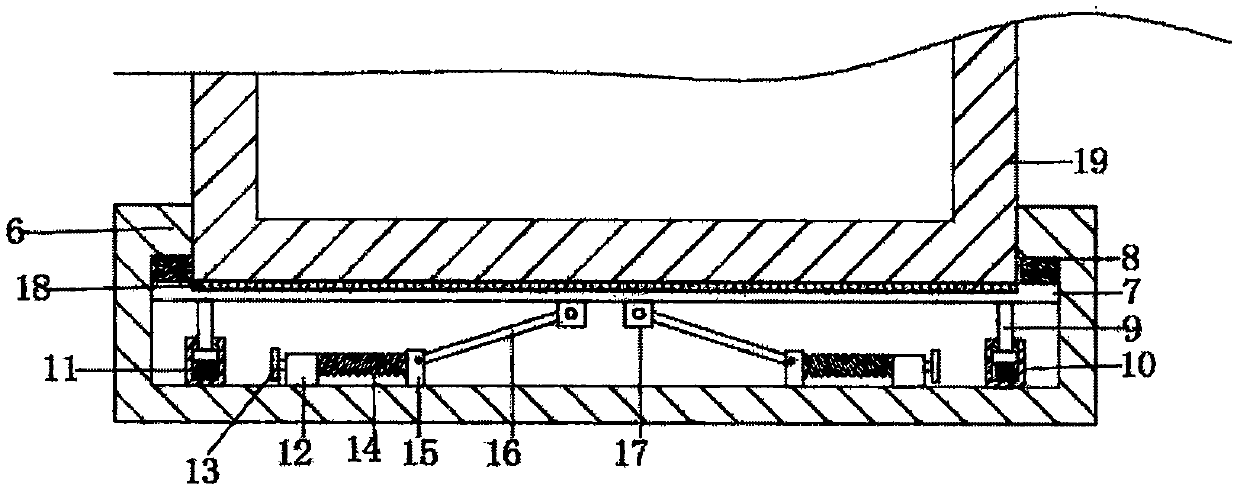

[0020] Such as Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: a lubricating oil viscosity detection device, including a placement mechanism 1, an adjustment mechanism 2 and a detection mechanism 3, an adjustment mechanism 2 is installed at one end of the top of the placement mechanism 1, and the adjustment One side of the mechanism 2 is fixedly equipped with a detection mechanism 3, and the placement mechanism 1 is composed of a support base plate 4, a support foot 5, a buffer groove 6, a buffer support plate 7, a buffer spring 8, a buffer rod 9, a shock absorber groove 10, a shock absorber Spring 11, fixed block 12, unloading slide rod 13, unloading spring 14, push slide block 15, transmission rod 16, connecting block 17, rubber pad 18, material barrel 19, semiconductor refrigeration sheet 20 and electric heating plate 21 are composed, The central position of the top of the support base plate 4 is fixedly equipped with a buffer groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com