Coal mine drum shearer

A shearer and drum technology, applied in cutting machinery, slitting machinery, earthwork drilling, etc., can solve the problems of inability to mine the coal seam, economic loss, and inability to adjust, and achieves the goal of increasing practicability and good crushing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

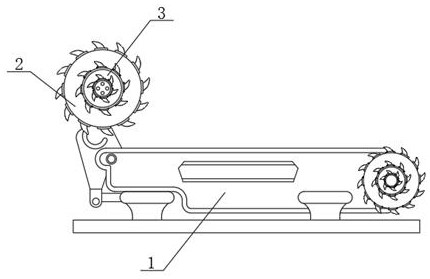

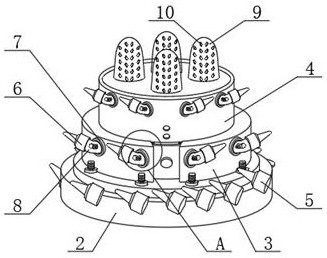

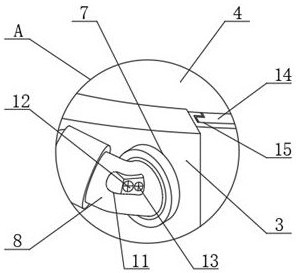

[0020] see Figure 1-5 , the present invention provides the following technical solutions: a coal mining drum shearer, comprising a shearer body 1, a drum 2 installed on the shearer body 1, and a first crushing head 5 on the surface of the drum 2, and one side of the drum 2 The first cohesive layer 3 is fixedly connected by bolts, and the side of the first cohesive layer 3 different from the drum 2 is provided with a second cohesive layer 4, and the first cohesive layer 3 and the second cohesive layer 4 are both annularly distributed with second fragments. The head 6, the surface of the first connecting layer 3 and the second connecting layer 4 are integrally formed with a swivel 7 at the position corresponding to the second crushing head 6, and a connecting block 8 is arranged between the second crushing head 6 and the swivel 7 , the inside of the swivel 7 is provided with a swivel 16, and the second crushing head 6 is connected with the swivel 7 through the connecting block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com