A construction plant pile foundation and a construction plant piling technology using the pile foundation

A technology for pile foundations and workshops, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the problems of poor stability of construction workshops, low bearing capacity of pile foundations, and poor pressure bearing capacity, so as to reduce potential safety hazards and improve bearing capacity Ability, stability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

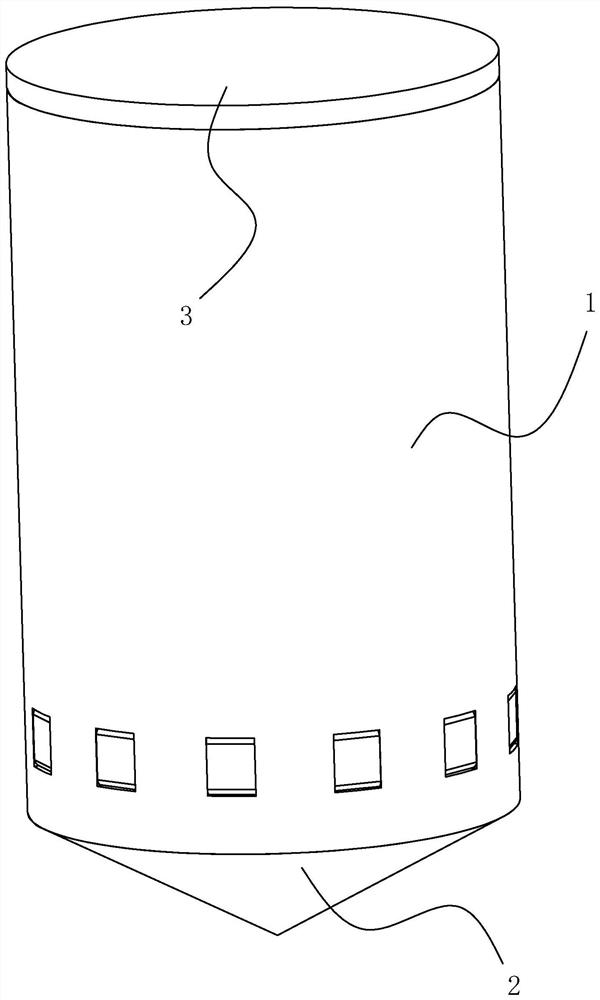

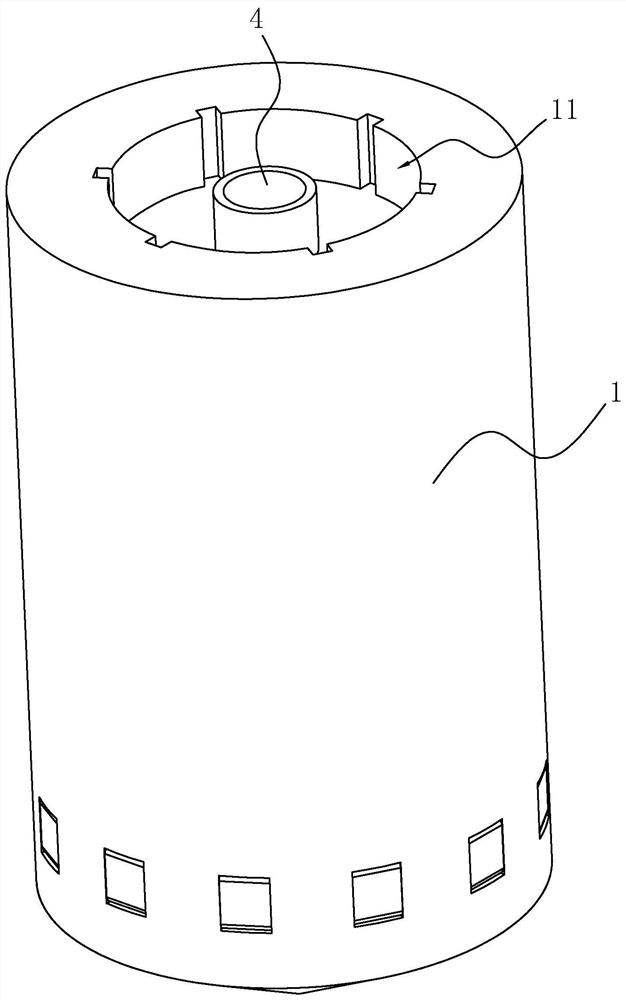

[0038] Embodiment 1: A kind of construction plant pile foundation, refer to the attached figure 1 , including a cylindrical pile basic body 1, a pile tip 2 fixedly connected to the bottom of the pile basic body 1, and a connecting pipe 4 fixedly connected to the middle position of the top of the pile basic body 1; the pile tip 2 is conically arranged and connected to the pile The base body 1 is coaxial, and the sharp corner of the pile tip 2 is located on the side of the pile tip 2 away from the pile base body 1; the connecting pipe 4 is arranged coaxially with the pile base body 1 .

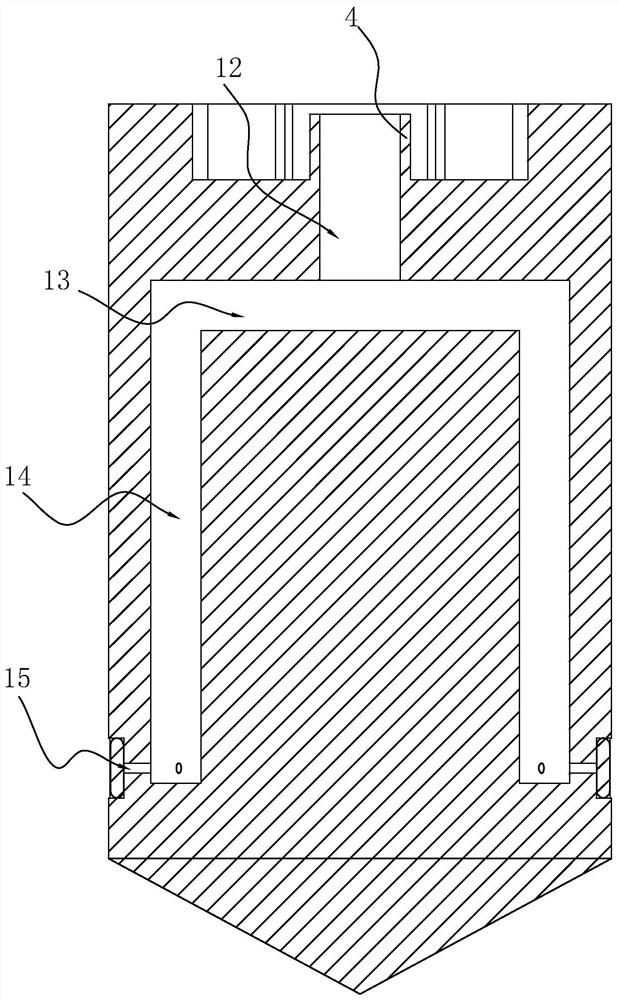

[0039] See attached figure 2 And attached image 3, the top of the pile basic body 1 is provided with a groove 11, the connecting pipe 4 is located in the groove 11, the height of the top of the connecting pipe 4 is lower than the height of the top of the groove 11; the groove 11 is circularly arranged and the groove 11 is connected to the The tube 4 is coaxially arranged; the bottom of the c...

Embodiment 2

[0043] Embodiment two: a kind of construction workshop piling process, comprises the following steps:

[0044] a. Determine the pile position: measure and mark the position on the ground where piles need to be driven;

[0045] b. Ground cleaning: Before piling, the ground needs to be cleaned up, and the construction site needs to be investigated, and overhead wires, underground wires, water supply and drainage pipes and other facilities that hinder the construction and affect the safe operation of the construction should be removed first. and displacement, and then carry out subsequent construction;

[0046] c. Pile driver in place: move the pile driver to the position where piling needs to be performed, and make the pile driver vertical, fix the fixed equipment such as locks for hoisting, and lift the basic body 1 of the pile so that the position of the pile tip 2 is aligned with the center of the pile position, Then slowly put the pile basic body 1 into the soil, and the...

Embodiment 3

[0050] Embodiment three: a kind of construction workshop piling process, comprises the following steps:

[0051] a. Determine the pile position: measure and mark the position on the ground where piles need to be driven;

[0052] b. Ground cleaning: Before piling, the ground needs to be cleaned up, and the construction site needs to be investigated, and overhead wires, underground wires, water supply and drainage pipes and other facilities that hinder the construction and affect the safe operation of the construction should be removed first. and displacement, and then carry out subsequent construction;

[0053] c. Pile driver in place: move the pile driver to the position where piling needs to be performed, and make the pile driver vertical, fix the fixed equipment such as locks for hoisting, and lift the basic body 1 of the pile so that the position of the pile tip 2 is aligned with the center of the pile position, Then slowly put the pile basic body 1 into the soil, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com