Rubber composition and rubber mixing method and low-tire-rolling-resistance tire using rubber composition

A rubber composition and a technology for the composition are applied in the direction of rolling resistance optimization, road transportation emission reduction, etc., which can solve the problems of rising tire rolling resistance, and achieve the effects of reducing hysteresis loss, satisfying durability, and reducing tire rolling resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

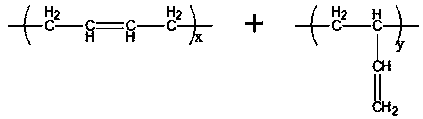

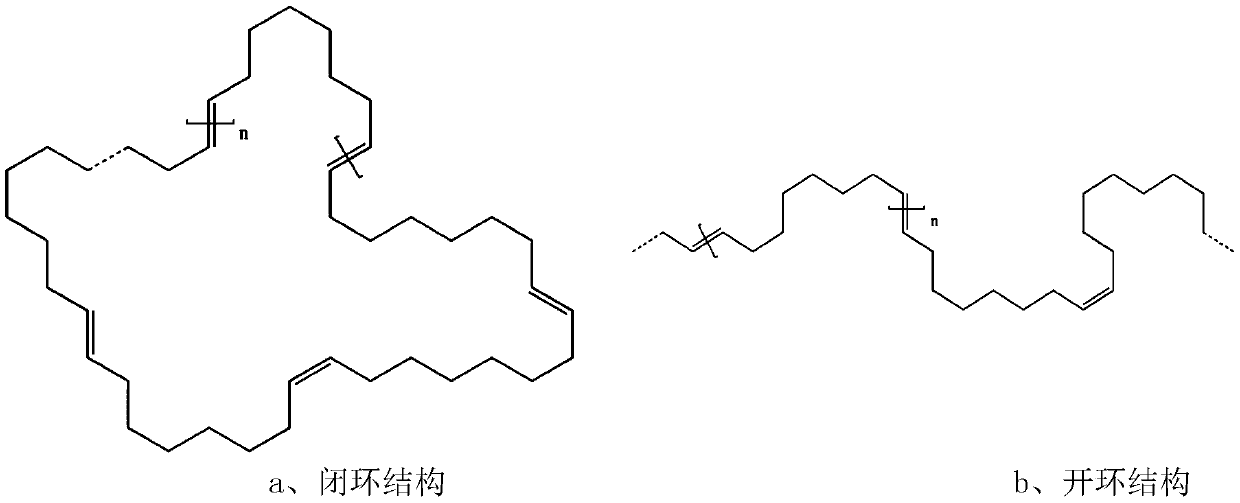

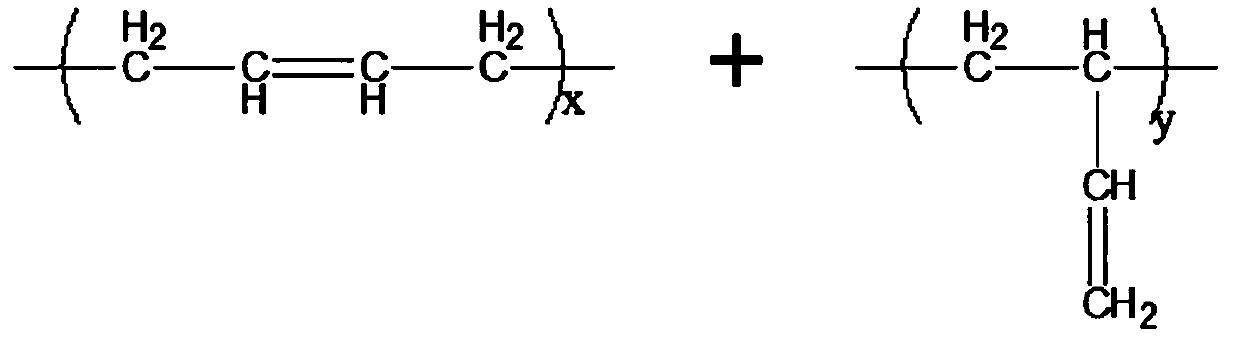

Image

Examples

Embodiment 1 to 7

[0040] Embodiments 1 to 7 are specifically as shown in Table 1 (parts by weight).

[0041] Table 1

[0042]

[0043]

[0044] Footnotes to Table 1

[0045] *1: SVR 3L natural rubber

[0046] *2: NS560 styrene-butadiene copolymer rubber, a product of Zeon Corporation of Japan

[0047] *3: VCR 412, product of Ube Corporation, Japan, 1,2-syndiotactic polybutadiene content is 12%

[0048] *4: VESTENAMER 8012, product of Evonik Degussa Specialty Chemicals Co., Ltd.

[0049] *5: Zeosil 200MP high-dispersion silica, Solvay chemical product, BET=185-205m 2 / g

[0050] *6: newsil 195MP ordinary silica, Wuxi Quecheng Chemical Products, BET=185-205m 2 / g

[0051] *7: Zeosil 1165MP high-dispersion silica, Solvay chemical product, BET=155-175m 2 / g

[0052] *8: Si69, Jingdezhen Hongbai Chemical Products

[0053] *9: N134 carbon black, Cabot product, iodine absorption value=142±5g / kg, DBP absorption value=127±5*10 -5 m 3 / kg

[0054] *10: N330 carbon black, Cabot product,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com