Non-shrinkage cementing material made of phosphogypsum and preparation method of non-shrinkage cementing material and concrete

A technology of cementitious material and phosphogypsum, applied in cement production and other directions, can solve problems such as improper control of raw material mix ratio, poor quality of concrete products, poor performance of cementitious materials, etc., so as to improve the value of comprehensive utilization of resources and save cement. Dosage, the effect of improving the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

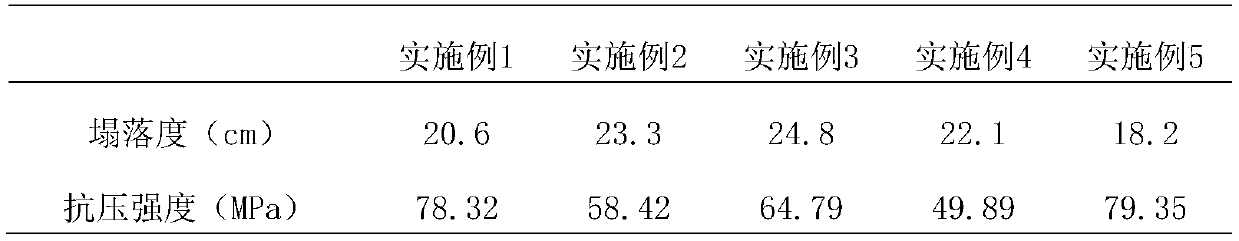

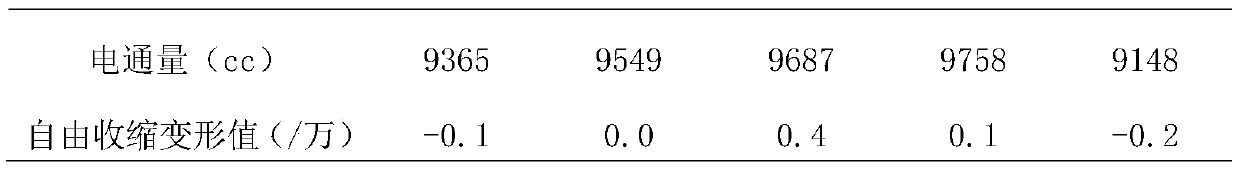

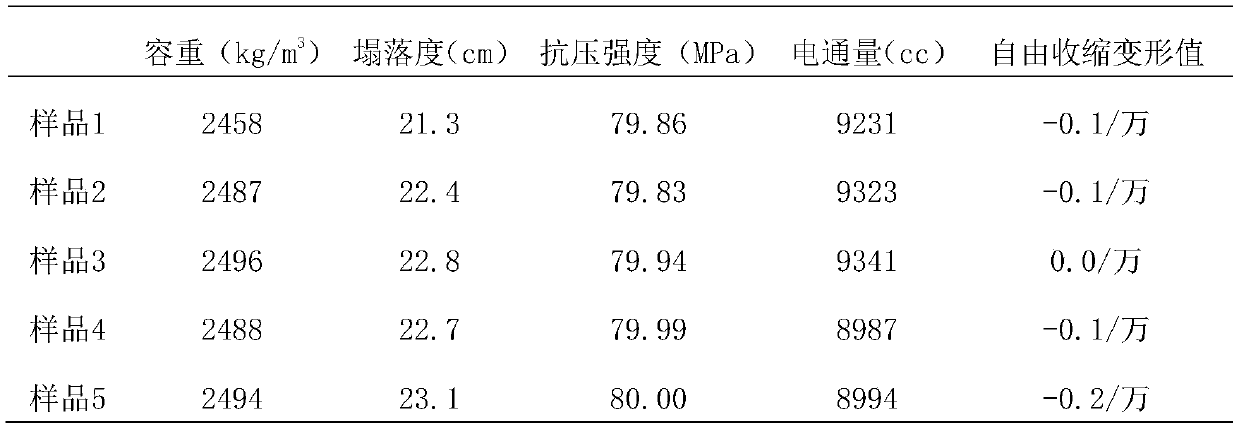

Embodiment 1

[0025] The cementitious material is mixed with ordinary portland cement, and the mixed material is composed of 5% phosphogypsum, 60% mixture of fly ash and phosphorus slag, 15% water-quenched slag, and 20% steel slag in weight percentage. It is mixed; the mass ratio of mixed material to 42.5 ordinary Portland cement is 1:7.

Embodiment 2

[0027] The cementitious material is mixed with ordinary portland cement, wherein the mixed material is composed of 20% phosphogypsum, 30% phosphorus slag, 30% water-quenched slag and 20% steel slag in weight percentage; the mixed material and 52.5 The mass ratio of ordinary Portland cement is 1:9.

Embodiment 3

[0029] The cementitious material is mixed with ordinary portland cement, and the mixed material is composed of 20% phosphogypsum, 40% fly ash, 30% water-quenched slag and 10% steel slag in weight percentage; the mixed material The mass ratio to 42.5 ordinary Portland cement is 3:7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com