Deviation preventing roller and deviation preventing system formed same

An anti-offset and anti-offset technology, which is applied to the general parts of printing machinery, printing, rotary printing machines, etc., can solve the problem of unsatisfactory anti-offset effect, improve the printing quality of printed products, and prevent lateral offset , excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

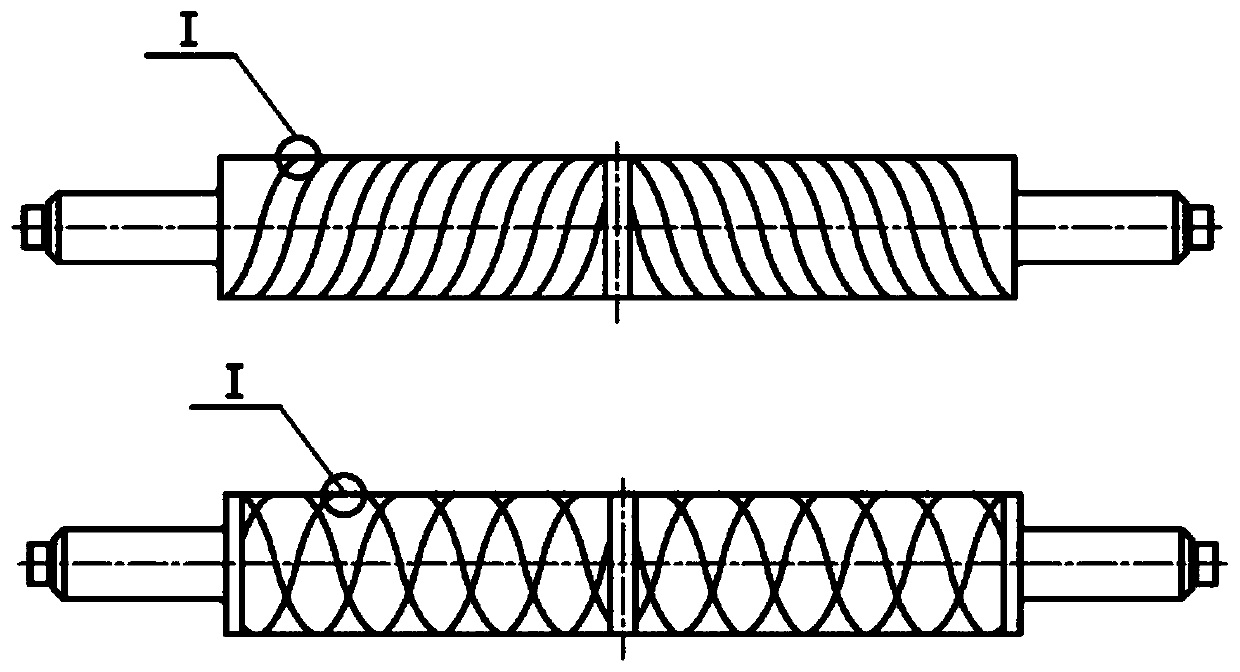

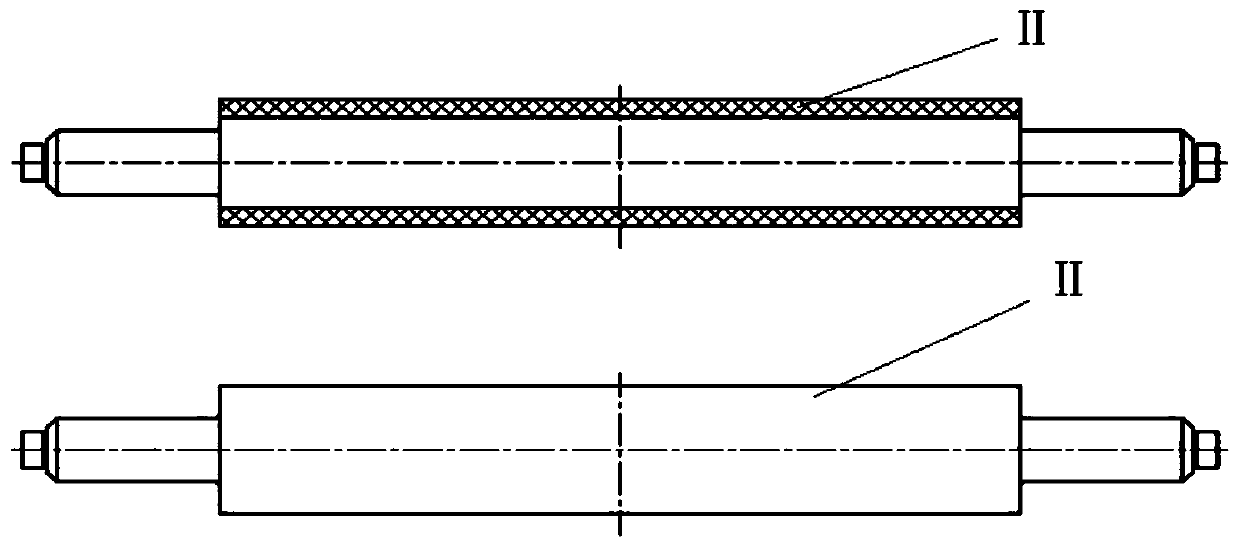

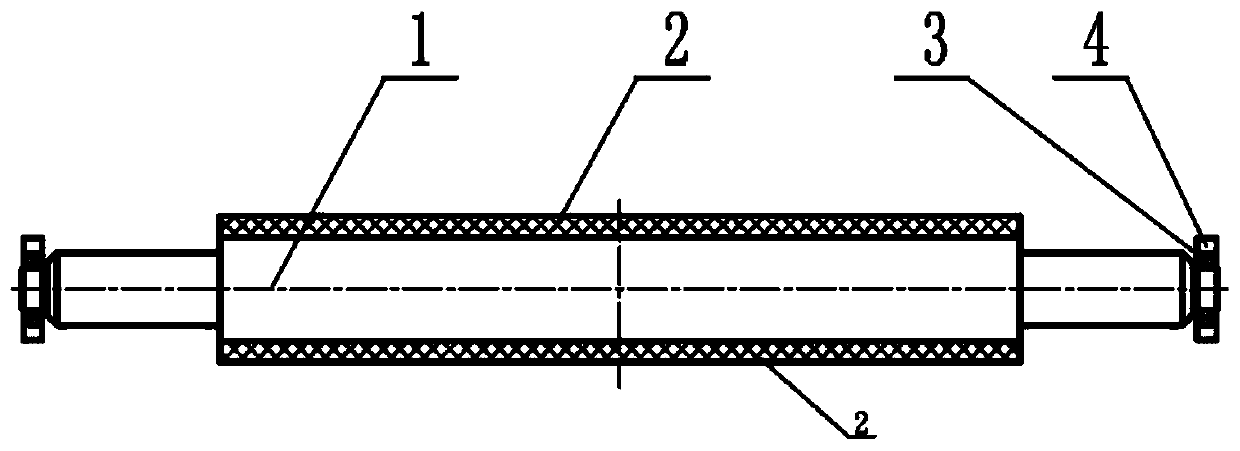

Method used

Image

Examples

no. 3 example

[0069] The above-mentioned third embodiment has the following three situations;

[0070] In the first case, theoretically the kerf regulator can be made infinitely thin so that it is located in the annular kerf without damaging the elastic skin.

[0071] In the second case, the cut regulator has a certain thickness (determined by the actual process), and the upper edge of the cut regulator is made to be on the same plane as the elastic surface and has the same horizontal damping force, which can just fill the circular cut The resulting unevenness makes the surface of the anti-deflection roller completely flat.

[0072] In the third case, the cut mark regulating member has a certain thickness (determined by the actual process), and this thickness is the limit that the process can achieve. The upper edge of the notch regulating member is located in the elastic surface layer, slightly lower than the plane where the elastic surface layer is located. For example, the distance fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rubber hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com