Three-dimensional stereoscopic textile fabric with antibacterial, moth-proof and aromatic functions and application thereof

A three-dimensional, fabric technology, applied in the field of textiles, can solve the problems of passenger discomfort, difficulty in recycling, inability to achieve antibacterial, deodorant, insect repellent, aroma, etc., and achieve long-lasting aroma, stable physical structure, and delamination Not easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

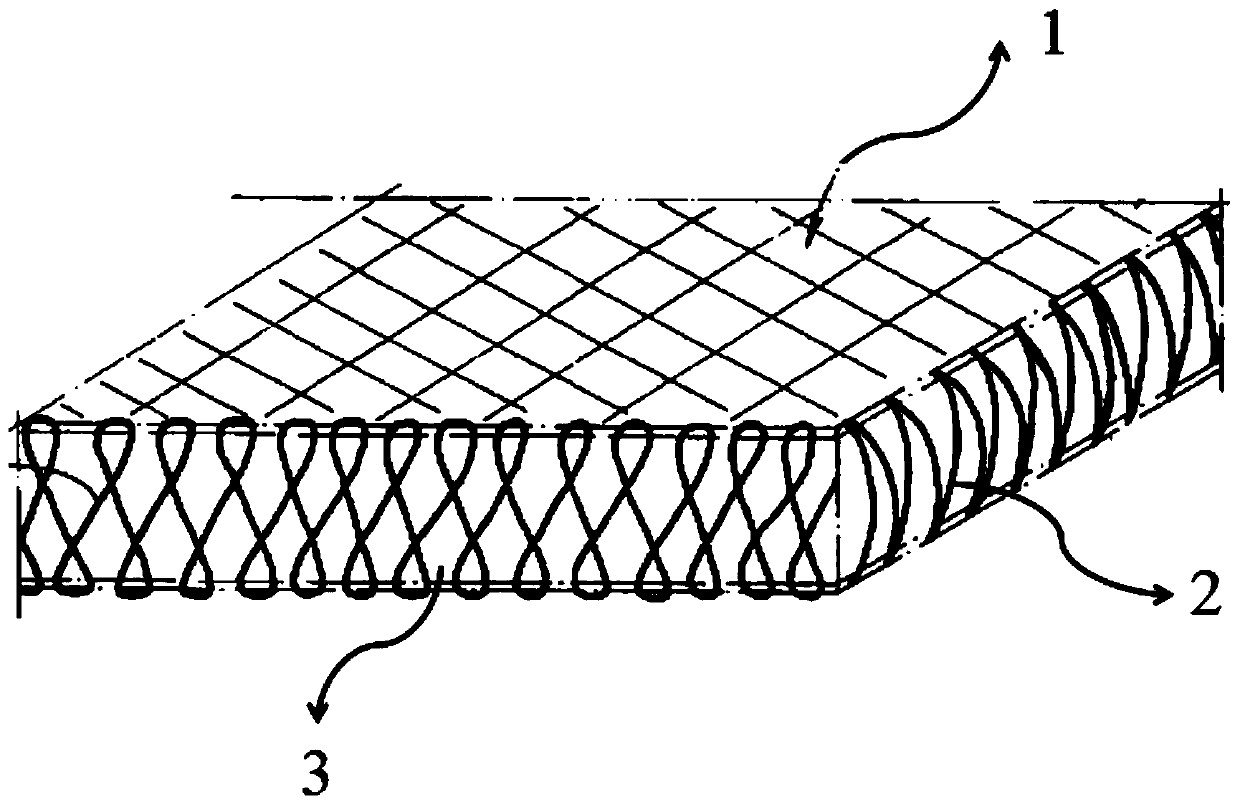

[0032] refer to figure 1 , the three-dimensional textile fabric with antibacterial, anti-moth, and aromatic functions of the present invention includes an upper surface fabric 1, an intermediate support fiber layer 2 and a lower surface fabric 3 arranged from top to bottom in sequence.

[0033] As an optional embodiment, the thickness ratio of the upper surface layer fabric 1 , the middle supporting fiber layer 2 and the lower surface layer fabric 3 is 1:3˜5:1.

[0034] As an optional embodiment, the middle supporting fiber layer 2 is weaved between the upper surface fabric 1 and the lower surface fabric 3 to form a three-dimensional structure. With such an arrangement, the combination of the upper surface layer fabric 1 and the lower surface layer fabric 2 can be realized without using chemical adhesives, thereby avoiding the peculiar smell produced by the adhesives.

[0035] As an optional embodiment, the upper surface fabric 1 is woven from flexible fibers, the flexible f...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that the flexible fiber is selected from or DTY 78Dtex / 24F polyester.

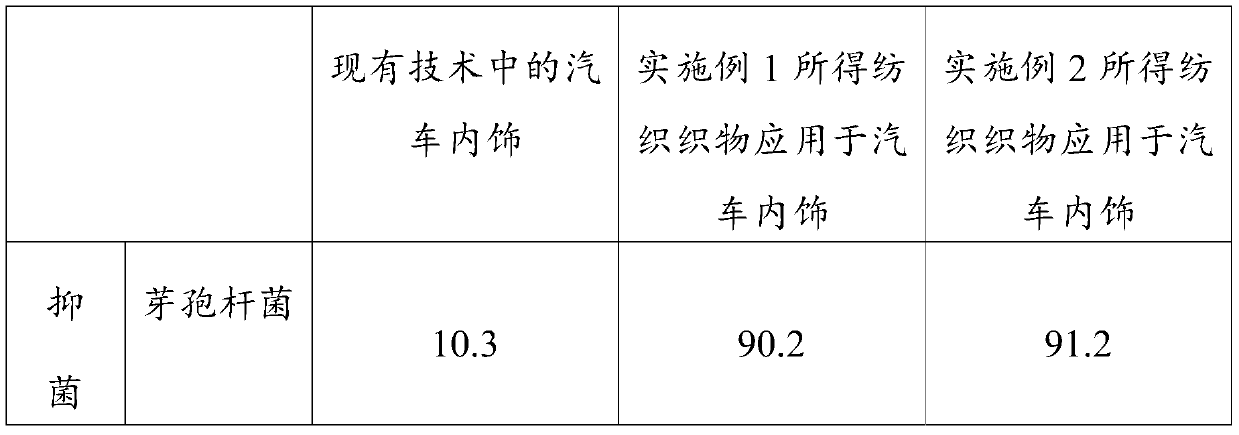

[0042] The three-dimensional textile fabric with antibacterial, moth-proof and aromatic functions described in the present invention is now applied to automobile interiors, and the antibacterial performance test is first carried out, specifically as follows:

[0043] The antibacterial performance test is based on GB / T 20944.2-2007 "Evaluation of Antibacterial Performance of Textiles". According to common sense, the common fungi and bacteria in the air are mainly bacillus, pigment-producing bacteria and fungal spores. The experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com