Wood shaving machine capable of improving surface flatness of furniture wood

A technology for wood surface and flatness, which is used in the manufacture of flat surface processing machines, planers, wood processing appliances, etc. It can solve problems such as environmental impact, low precision, and a large amount of dust, reducing pollution and manipulation errors. , the effect of reducing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

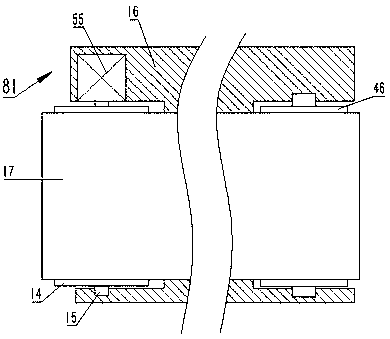

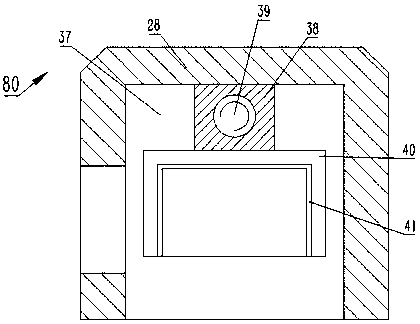

[0022] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are now defined as follows: figure 1 The direction of the view direction is the same as the front, back, left, right, and bottom directions. figure 1 It is a front view of the device of the present invention, figure 1 The directions shown are consistent with the front, rear, left, right, up, and down directions of the front view of the device of the present invention.

[0023] refer to Figure 1-5 , according to an embodiment of the present invention, a shaving machine that can improve the flatness of the surface of furniture wood includes a device box 10, the top surface of the device box 10 is symmetrically fixed to the left and right to install the top seat 24, the left and right sides The tool housing 28 is hingedly installed on the top seat 24 of the tool housing 28, and a processing mechanism 80 that can directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com