Assembly process of rotor and end cover in brushless motor and assembly equipment

A technology of brushless motor and assembly process, which is applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve the problems of poor motor performance consistency, uncontrollable installation size, and rotor up and down movement. Achieve the effect of good assembly effect, precise control of installation size, and reduction of movement clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

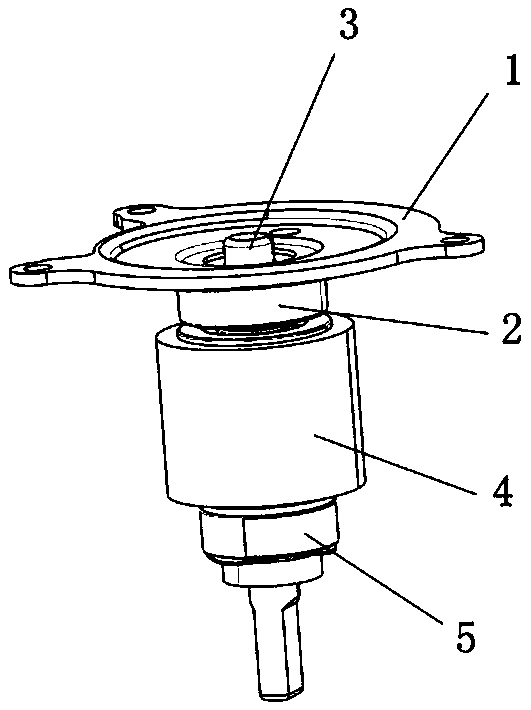

[0033] like figure 1 As shown, the rotor assembly in the brushless motor includes a rotor shaft 3, a rotor magnetic ring 4 is sleeved in the middle of the rotor shaft 3, a lower bearing 5 is sleeved under the rotor magnetic ring 4, and the upper end of the rotor shaft 3 is an end cover Component 9.

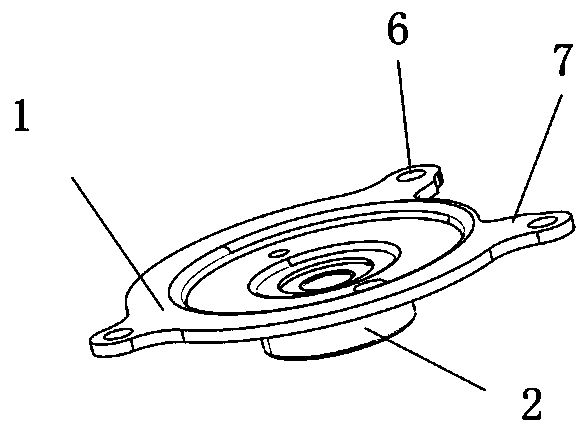

[0034] like figure 2 As shown, the end cover assembly in the brushless motor includes an end cover 1 , and an upper bearing 2 is installed in the center of the end cover 1 . The outer circumferential surface of the end cover 1 is integrally formed with three lugs 7 , and the lugs 7 are provided with positioning holes 6 .

[0035] The assembly process for assembling the end cap assembly to the rotor is as follows:

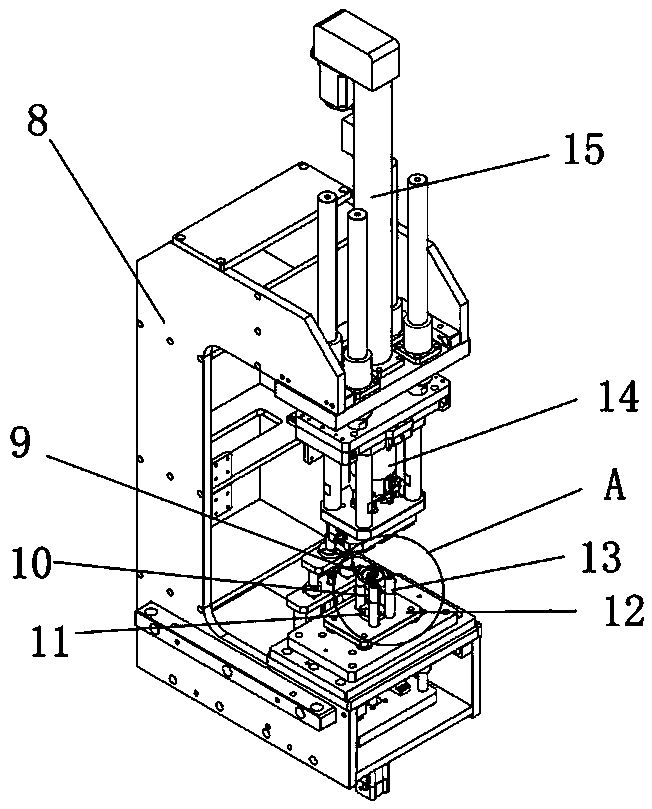

[0036] In the first step, the rotor 10 is placed on the lower mold 12, the rotor shaft 3 is placed in the positioning hole in the lower mold, the three uprights 13 around the positioning hole are lifted, and the end cap assembly 9 is placed on the upright post 13. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com