Automatic focusing lens module

A technology for auto-focusing and focusing lenses, applied to focusing devices, installations, optics, etc., can solve problems such as easy tilting, low material precision, and unsmooth rotation of the outer adjustment ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

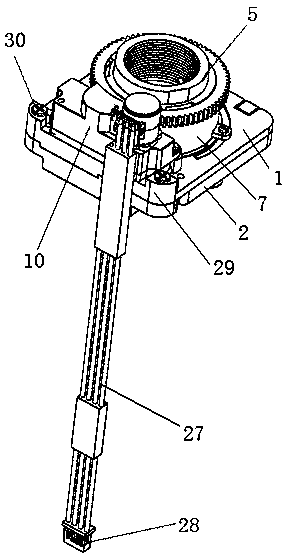

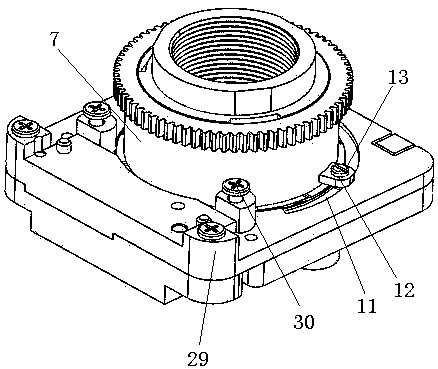

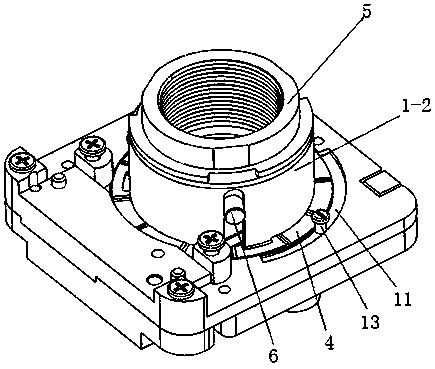

[0037] Such as figure 1 As shown, the embodiment of the present invention discloses an auto-focus focusing lens module, including a cover plate 1, such as Figure 6 As shown, the cover plate 1 includes a plate-shaped connecting portion 1-1, a through hole is provided in the middle of the plate-shaped connecting portion 1-1, and a cylindrical connecting portion 1-1 extending upward is provided in the through hole. 2. An IR-CUT assembly is arranged between the plate-shaped connecting part 1-1 and the fixing seat 2. The cylindrical connecting portion 1-2 is provided with more than two elongated holes extending up and down, and the inner side of the plate-shaped connecting portion 1-1 is provided with rectangular holes corresponding to the elongated holes and communicating with each other. A corrugated shrapnel placing groove 3 is provided on the plate-shaped connecting portion close to the cylindrical connecting portion, and a corrugated shrapnel 4 is arranged in the corrugated ...

Embodiment 2

[0049] The specific structure of the second embodiment differs from that of the first embodiment in that: the specific forms of the elastic device, the cylindrical connecting portion and the outer adjustment cylinder are different. In this embodiment, the same content as the embodiment will not be repeated.

[0050] Specifically, such as Figure 9-14 As shown, the embodiment of the present invention discloses an auto-focus focusing lens module, including a cover plate 1, and the cover plate 1 includes a plate-shaped connecting portion 1-1, and a through hole is arranged in the middle of the plate-shaped connecting portion 1-1. A cylindrical connecting portion 1-2 extending upward is provided in the through hole. The cylindrical connecting portion 1-2 is provided with three elongated holes extending up and down, the outer diameter of the picture frame 5 is equal to the inner diameter of the cylindrical connecting portion 1-2, and the radial direction of the picture frame 5 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com