Method for manufacturing radio frequency coaxial cable and wrapping equipment used therefor

A radio frequency coaxial cable, wrapping technology, applied in circuits, electrical components, waveguides, etc., can solve problems such as affecting cable performance, and achieve the effect of eliminating voltage standing wave ratio peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to facilitate the understanding of various aspects, features and advantages of the technical solutions of the present invention, the present invention will be specifically described below in conjunction with the accompanying drawings and exemplary embodiments. It should be understood that the various embodiments described below are only for illustration, but not for limiting the protection scope of the present invention.

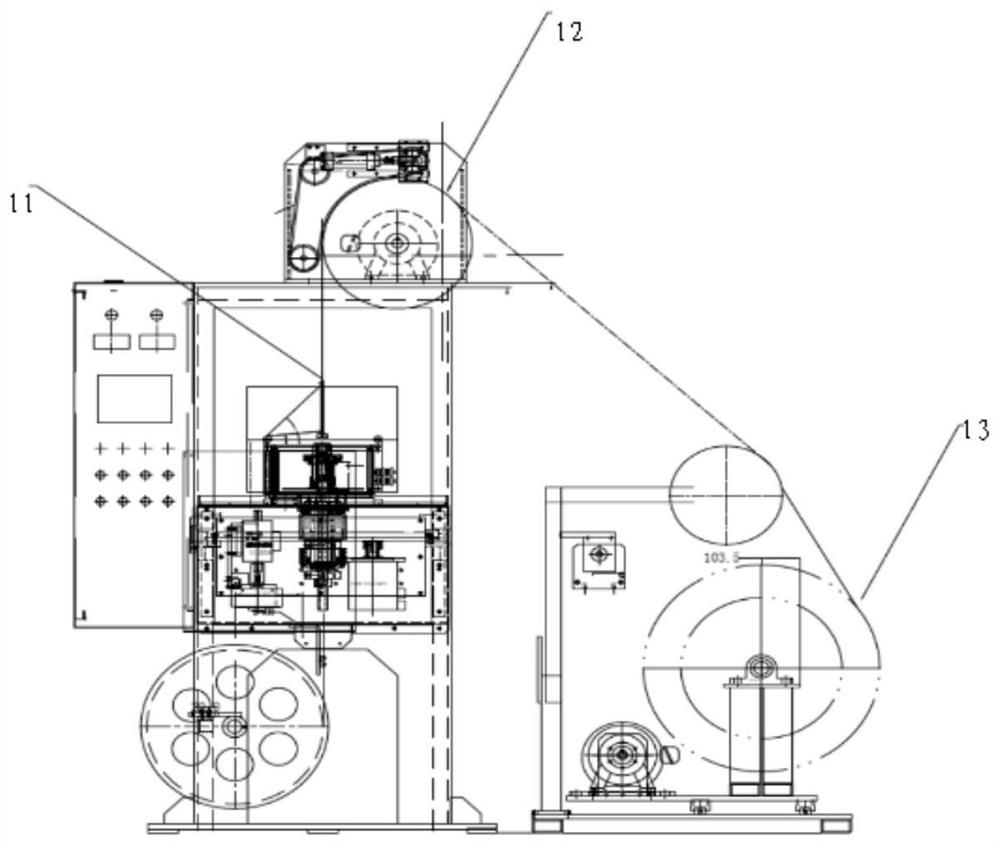

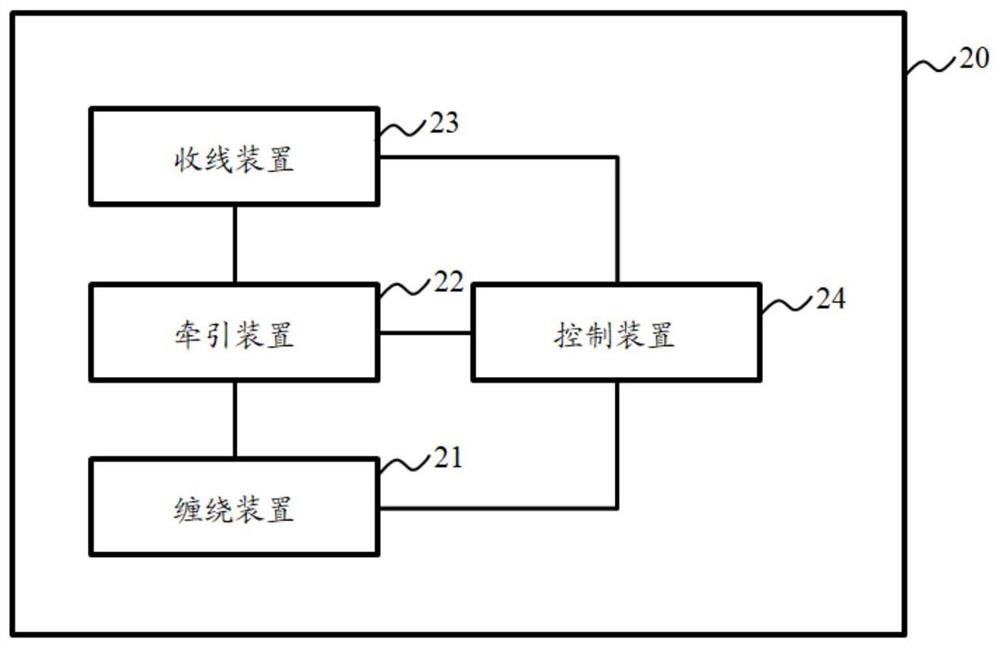

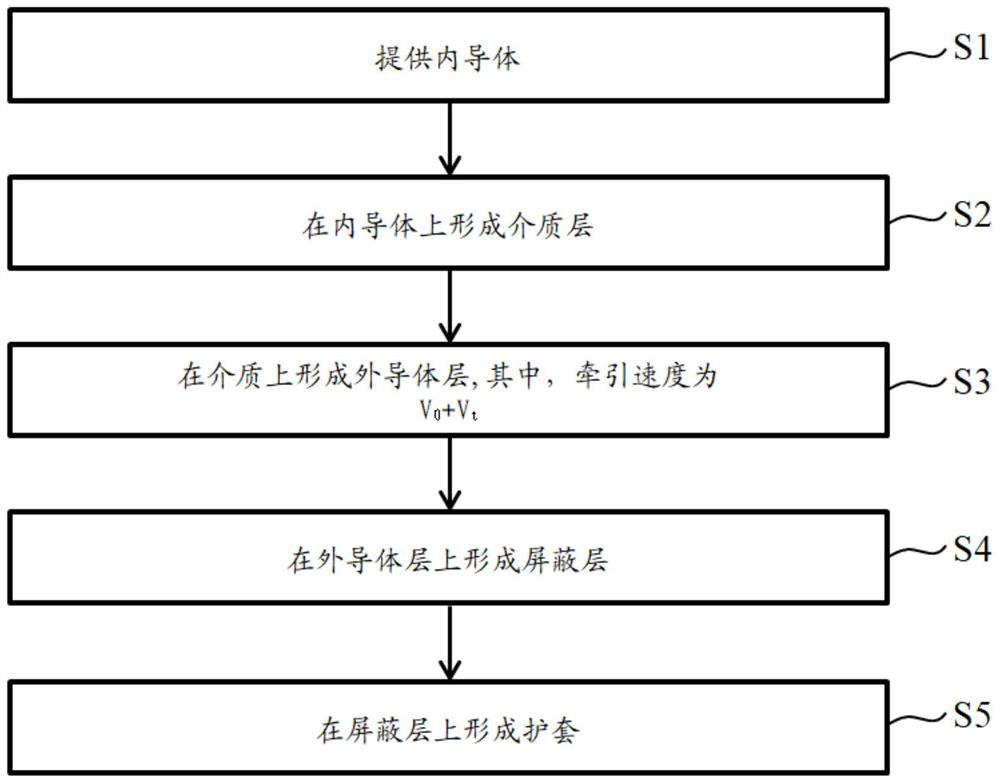

[0037] figure 2 A schematic diagram of component modules of a wrapping device according to an embodiment of the present invention is shown. Such as figure 2 As shown, the wrapping device 20 of this embodiment includes a wrapping device 21 , a pulling device 22 , a wire take-up device 23 , and a control device 24 . Wherein, the structures of the winding device 21 , the pulling device 22 and the take-up device 23 are respectively the same as those of the traditional wrapping equipment. figure 1 A schematic structural diagram of a typical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com