Method for analyzing absolute energy efficiency and relative energy efficiency of compressed air system

A technology of compressed air and analysis method, applied in relative volume flow measurement, liquid/fluid solid measurement, instruments, etc., can solve problems such as judging system operation status, lack of single-machine analysis basis, and differences in operating characteristics of air compressor stations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The invention is oriented to the complex compressed air system, establishes a system for energy efficiency analysis of single machine and air compressor station operation, and constructs a mathematical model for corresponding energy efficiency analysis. Firstly, different from the traditional energy efficiency analysis system, the present invention proposes the concepts of absolute energy efficiency analysis and relative energy efficiency analysis.

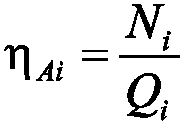

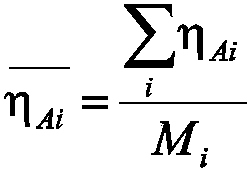

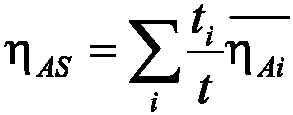

[0080] 1. Absolute running energy efficiency analysis

[0081] The absolute energy efficiency analysis system is divided into two parts, one is the absolute operation energy efficiency analysis of a single machine; the other is the overall absolute operation energy efficiency analysis of the air compressor station based on the single machine analysis and considering the characteristics of the single machine running time. The basic ideas and models are as follows:

[0082] 1) Absolute running energy efficiency analysis of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com