A kind of fracturing process method of double branch well

A process method and branch well technology, which are applied in the fields of earthwork drilling, wellbore/well components, and production fluids, etc., can solve the problems of long operation cycle, high overall cost, large manpower and material resources, etc., so as to reduce the operation links and shorten the operation. cycle, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

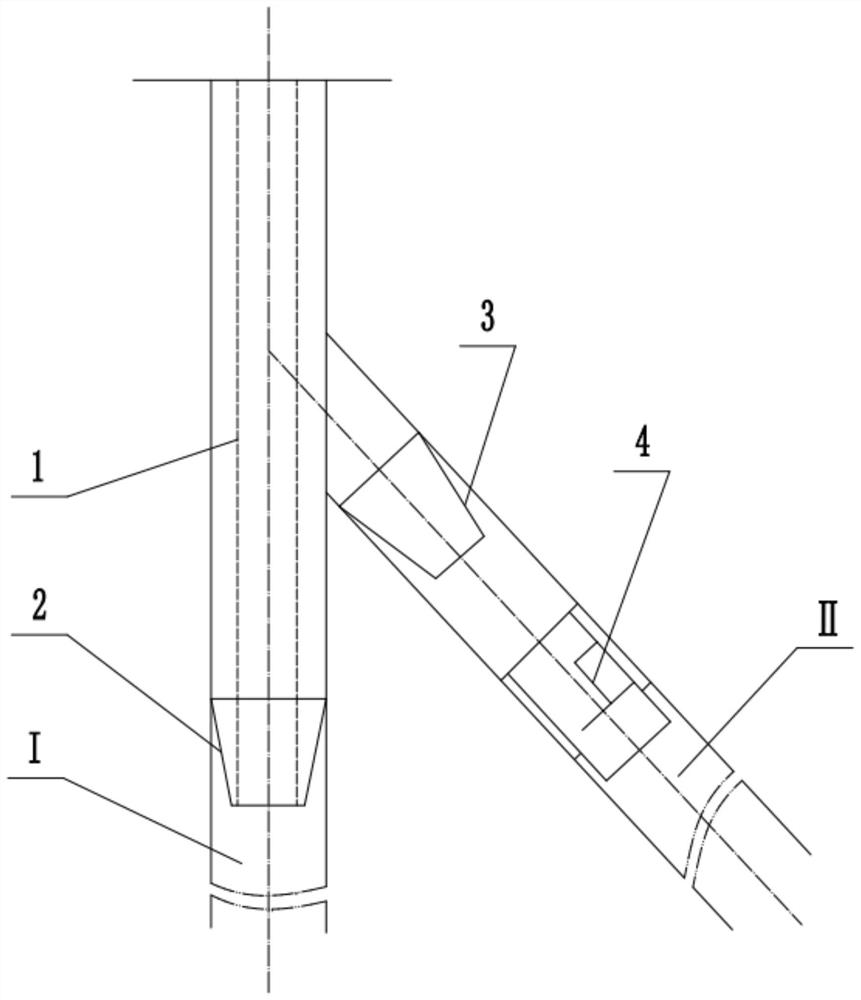

[0008] Such as figure 1 As shown, a dual-branch well fracturing process, the method steps are as follows: After the main wellbore I is drilled, use the temporary plugging tool for the construction of the branch well and the main wellbore to insert the butt joint 2 back, seal the main wellbore I, and then plug the main wellbore I The upper wellbore sidetracked the second branch wellbore II by windowing, and after the second branch wellbore II was drilled, the completion string including the second branch wellbore back-insertion butt joint 3 and the branch temporary plugging and isolation tool 4 was lowered. The fracturing reinsertion inner pipe string 1 is first reinserted into the second branch wellbore reinsertion docking cylinder 3 . Then remove the surface drilling rig equipment, move it to the fracturing equipment and supporting wellheads, and perform fracturing reconstruction on the second branch wellbore II. After the fracturing of the second branch wellbore II, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com