Assembled aluminum grating installation structure

An installation structure and prefabricated technology, which is applied to building components, building structures, buildings, etc., can solve problems such as depression and low elevation of the top surface, and achieve the effects of labor saving, convenient construction, and advanced installation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

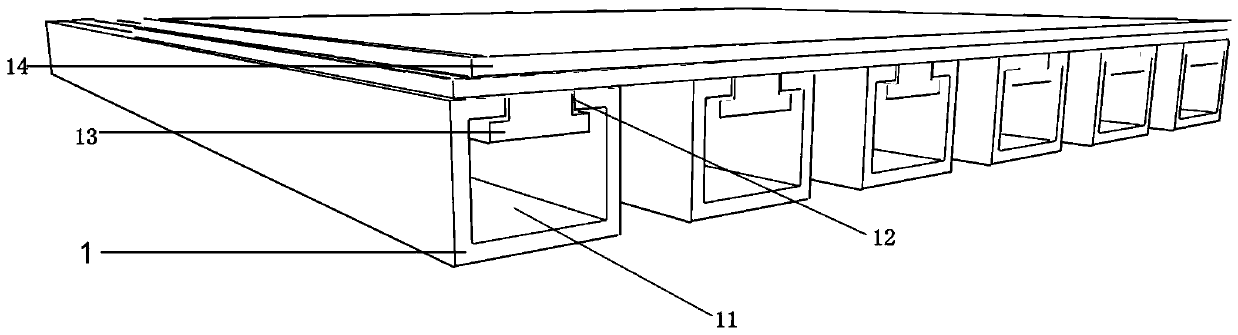

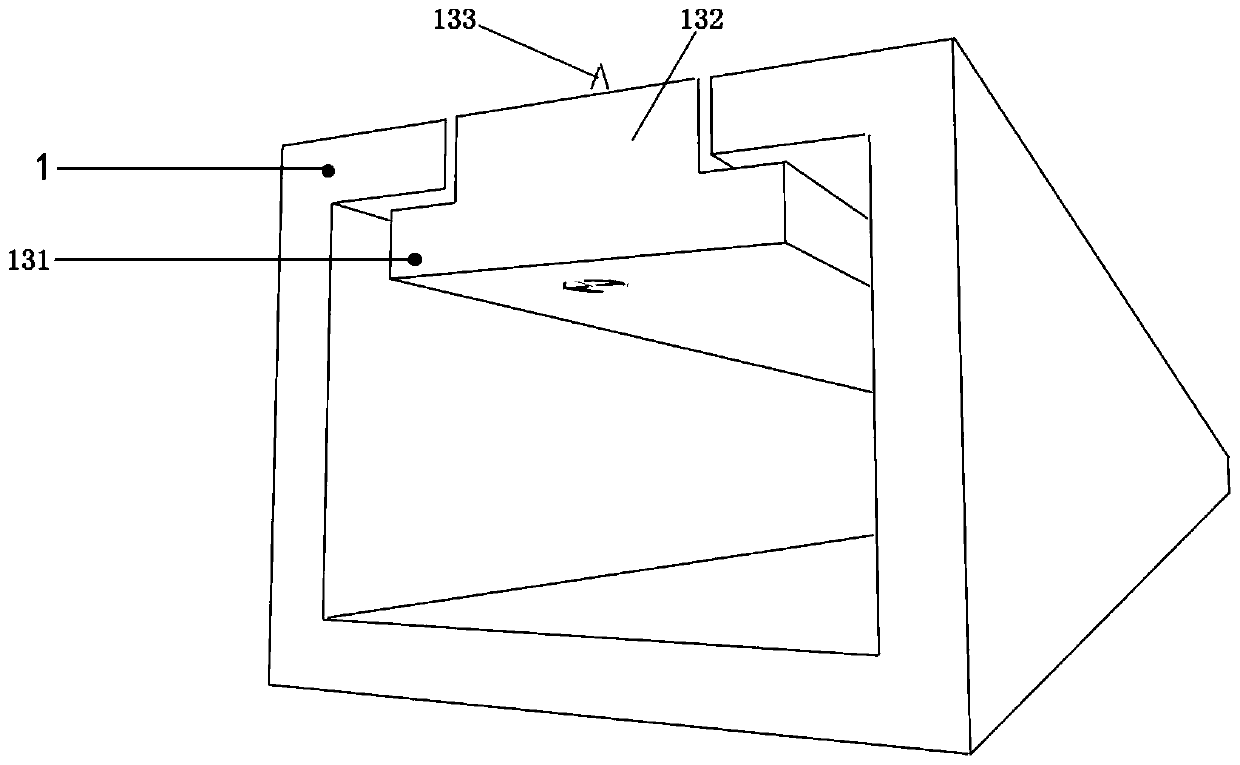

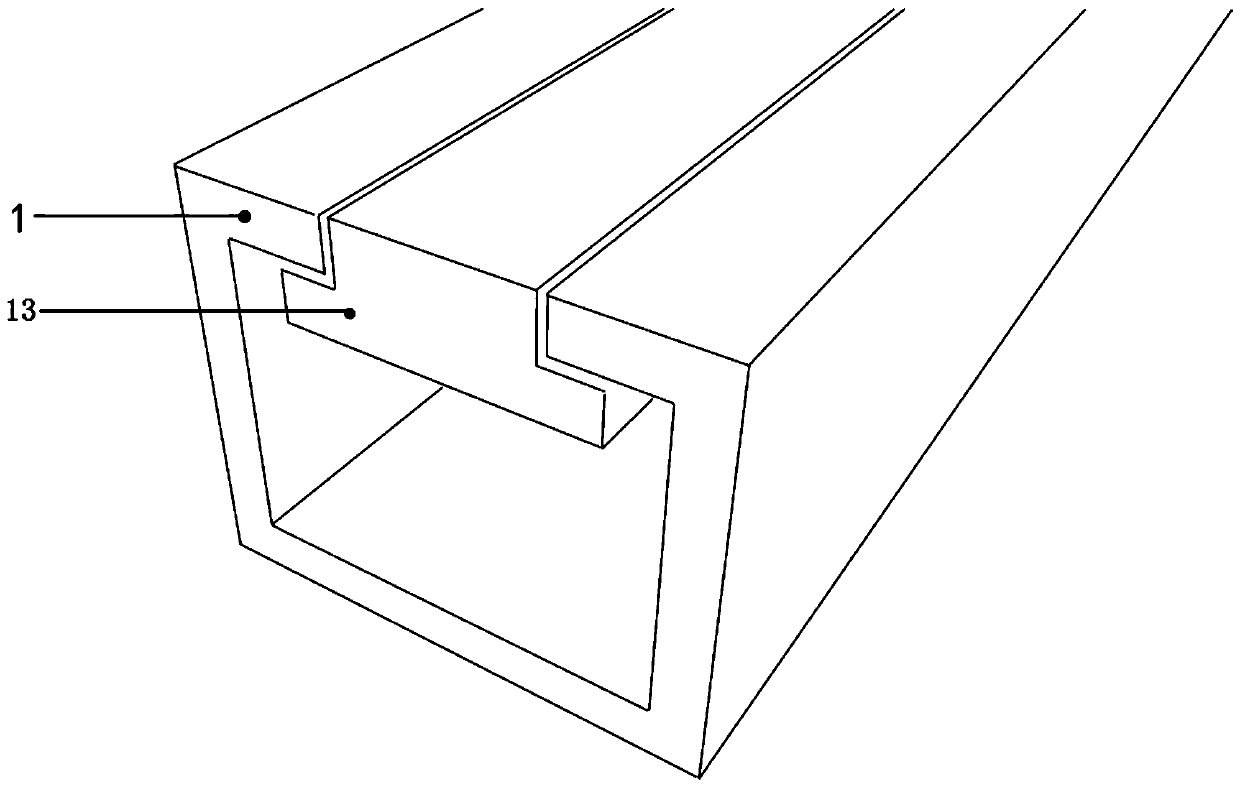

[0026] see Figure 1 to Figure 3 , the figure shows the installation structure of an assembled aluminum grid provided by Embodiment 1 of the present invention, which includes a plurality of grid bars 1 arranged in parallel, which are fixedly connected to the base layer, and the grid bars 1 are provided with The cavity 11, the bottom surface of the grating bar 1 is provided with a through hole 12 communicating with the cavity 11. The cavity 11 is a through cavity extending along the length direction of the grating bar 1, and the through hole 12 is a through hole extending along the grating bar 1. The long hole extending in the length direction of the cavity 11 and the through hole 12 are clamped with a T-shaped connector 13, the T-shaped connector 13 is a plate body with a T-shaped cross section, and the T-shaped connector 13 is fixedly connected by screws 133 Ceiling panels14.

[0027] Specifically, participate in Figure 1 to Figure 3 , the plate body includes a vertical ho...

Embodiment 2

[0038] see Figure 1 to Figure 3 , the figure shows the installation structure of a prefabricated aluminum grid provided by the second embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the horizontal plate The opposite ends of the 131 respectively extend toward the two opposite inner walls of the cavity 11 , and the ends of the horizontal plate 131 and the inner walls of the cavity 11 are connected by ball shafts. Through the improvement of the above structure, the function of the ball shaft is used to achieve an adaptive connection between the end of the horizontal plate and the inner wall of the cavity, so that no matter what the installation angle of the grille bar is, the T-shaped connector can realize self-adaptive connection. Leveling.

Embodiment 3

[0040] see Figure 1 to Figure 3 , the figure shows the installation structure of a prefabricated aluminum grating provided by the third embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the vertical plate There is a gap between the side end of 132 and the hole wall of the through hole 12, and a honeycomb plate gasket is arranged in the gap. Through the improvement of the above structure, it is possible to achieve a stable supporting effect on the T-shaped connector, and realize the moisture-proof and heat-dissipating effects of the ceiling board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com