Hot-dip galvanizing furnace nose with zinc ash blowing and diffusing treatment function

A furnace nose, hot-dip galvanizing technology, applied in hot-dip plating process, coating, metal material coating process and other directions, can solve problems such as restricting the product quality of hot-dip galvanizing units, and reduce zinc ash defects and enrichment. , the effect of reducing the probability of ash accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

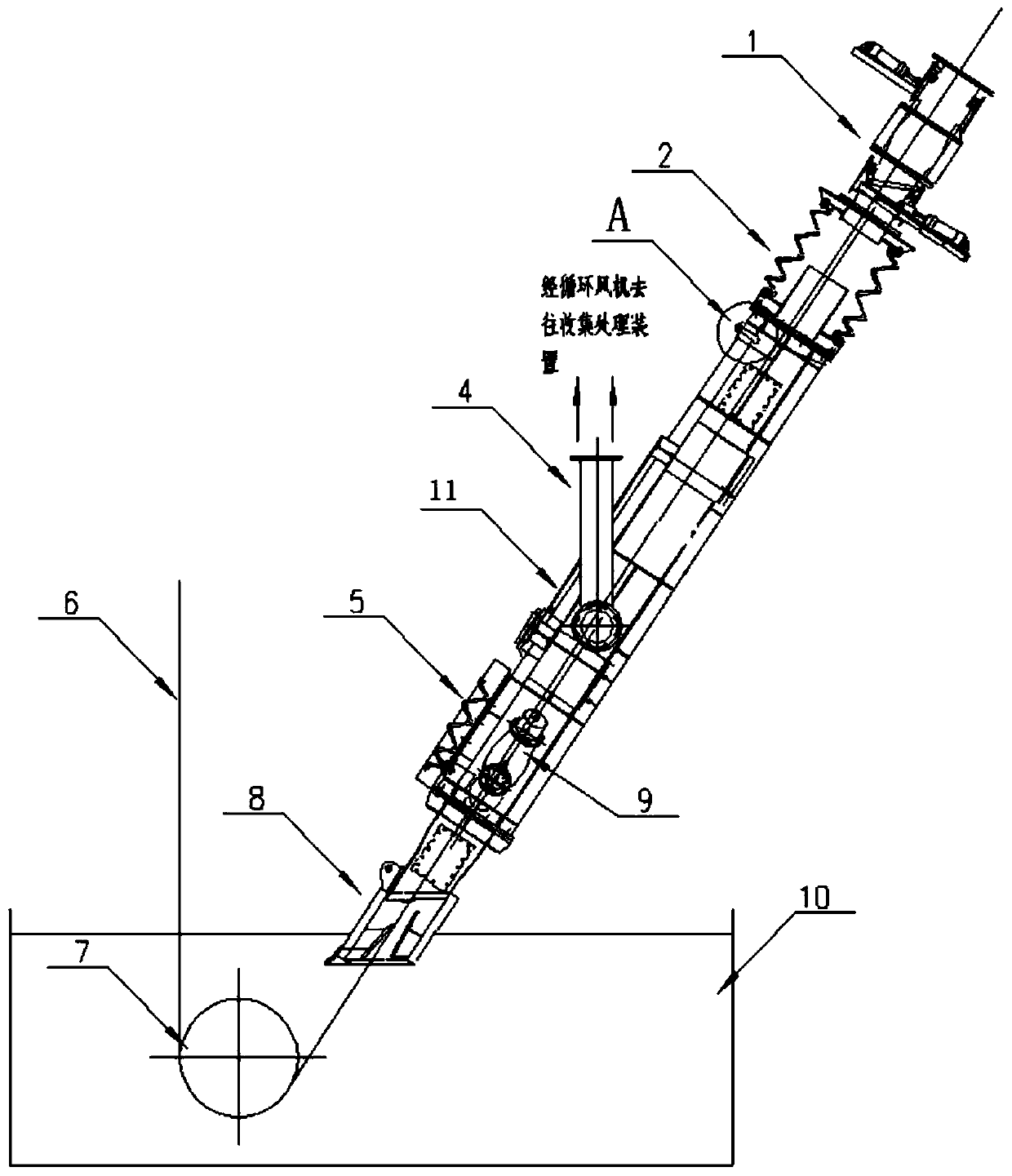

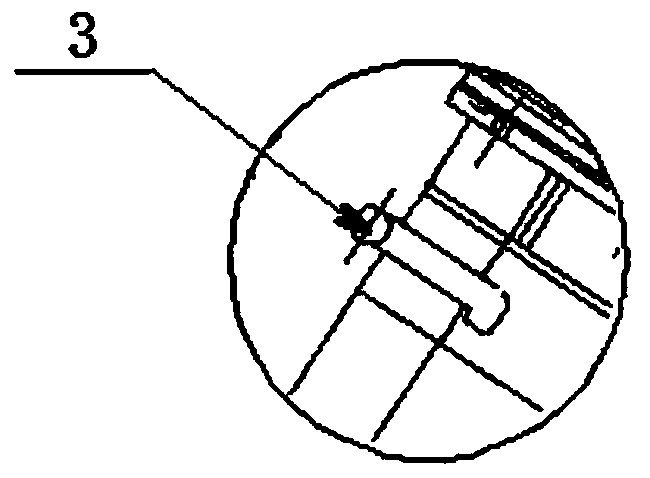

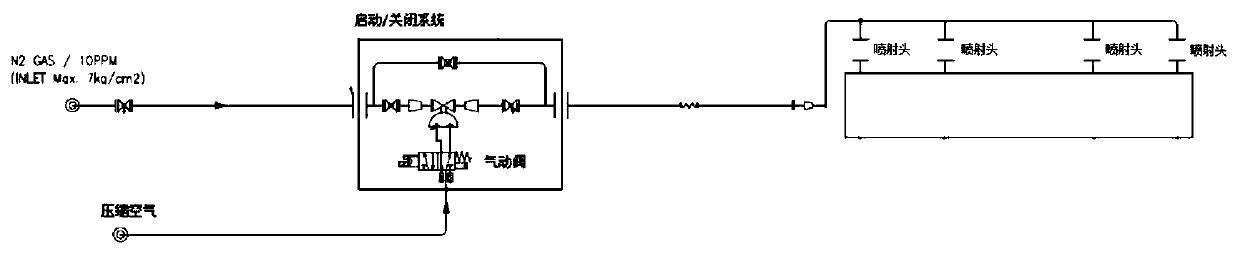

[0021] The strip steel 6 enters the zinc pot 10 through the furnace nose, passes through the sinking roller 7 and moves upwards to complete the hot-dip process; Nose tip stretches in the zinc pot 10). Such as figure 1 A hot-dip galvanized furnace nose with the function of spraying and releasing zinc ash is shown, including a furnace nose body 11, a heating and heat preservation system arranged at the lower part of the furnace grate body, and an injection system arranged at the upper part of the furnace nose body 11, And release system; The injection system includes and N 2 The blowing pipe 3 connected by the supply pipeline and the spraying head arranged at the end of the blowing pipe 3, the spraying head extends into the inside of the furnace nose body 11 and is arranged circumferentially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com