Engineering strain for fermented synthesis of ergothioneine and construction method thereof

An engineering strain and ergothioneine technology, applied in the field of bioengineering, can solve the problems of expensive synthetic raw materials, high extraction cost and high synthetic cost, and achieve the effects of efficient biosynthesis and wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

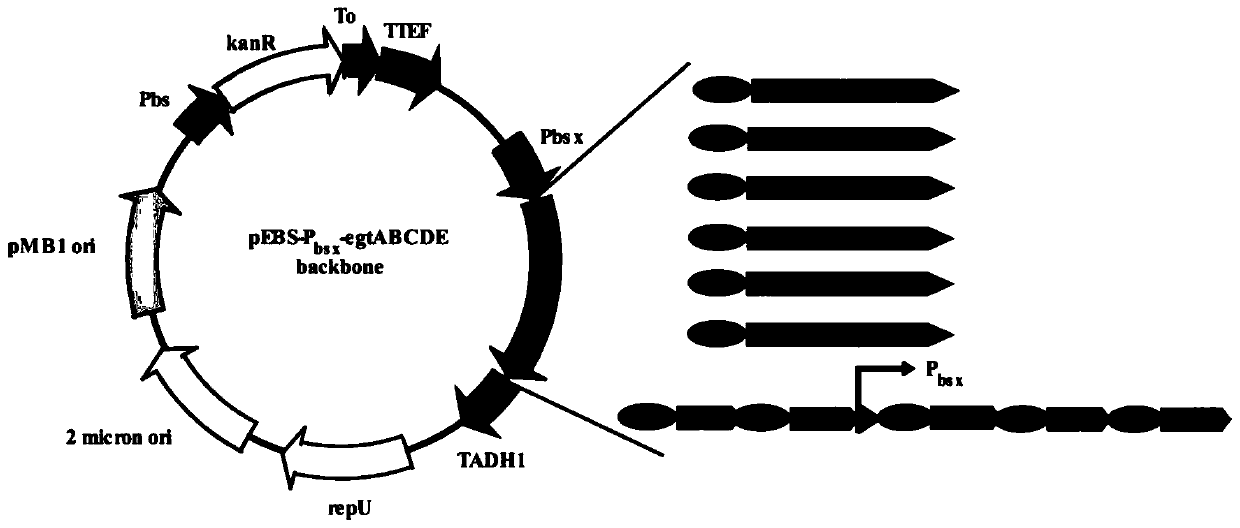

Method used

Image

Examples

Embodiment 124

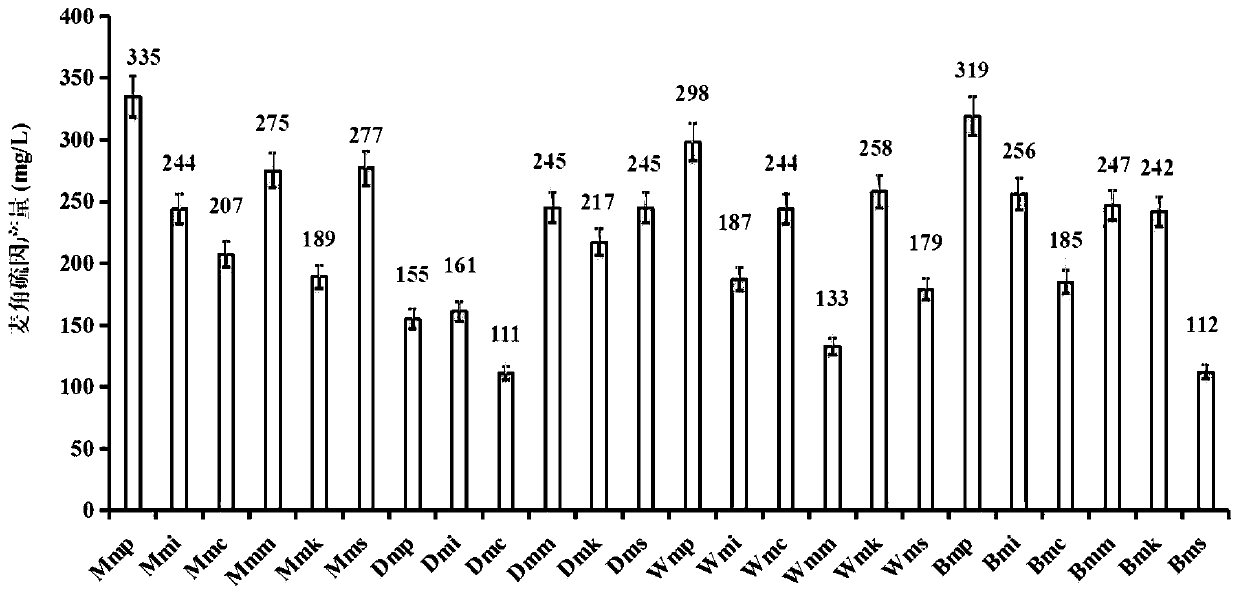

[0045] Example 1 Shake Flask Culture and Ergothioneine Content Determination of 24 Escherichia coli Recombinant Bacteria Strains Heterologously Expressing the egtABCDE Gene Cluster

[0046] Pick 24 Escherichia coli recombinant strains with heterologous expression of egtABCDE gene cluster constructed above and single clones of control bacteria (transformed pEBS empty plasmid) and inoculate them in 5 mL LB medium, and add kanamycin at a final concentration of 50 μg / mL as required , placed at 200rpm at 37°C for 10-12h, and then transferred to a 250mL Erlenmeyer flask with a 10% inoculum size. Kanamycin, then placed at 220rpm and cultured at 37°C, methionine, histidine betaine, histidine, and cysteine were added when culturing for 10 hours, and the final concentration of added methionine was 2g / L. The final concentration of histidine betaine is 10g / L, the final concentration of added histidine is 15g / L, the final concentration of added cysteine is 15g / L, and the final liquid v...

Embodiment 218

[0047] Example 2 Shake Flask Culture and Ergothioneine Content Determination of 18 Bacillus subtilis Recombinant Bacteria Strains Heterologously Expressing the egtABCDE Gene Cluster

[0048] Pick 18 recombinant strains of Bacillus subtilis with heterologous expression of the egtABCDE gene cluster constructed above and single clones of control bacteria (transformed with pEBS empty plasmid) and inoculate them in 5 mL LB medium, and add Kanamyces at a final concentration of 50 μg / mL as required cultured at 200rpm at 37°C for 10-12h, and then transferred to a 250mL Erlenmeyer flask with 10% inoculum size. Kanamycin, then cultured at 220rpm at 37°C, added methionine, histidine betaine, histidine, cysteine when cultured for 10h, and the final concentration of added methionine was 2g / L , the final concentration of histidine betaine added is 10g / L, the final concentration of histidine added is 15g / L, the final concentration of cysteine added is 15g / L, and the final liquid volume i...

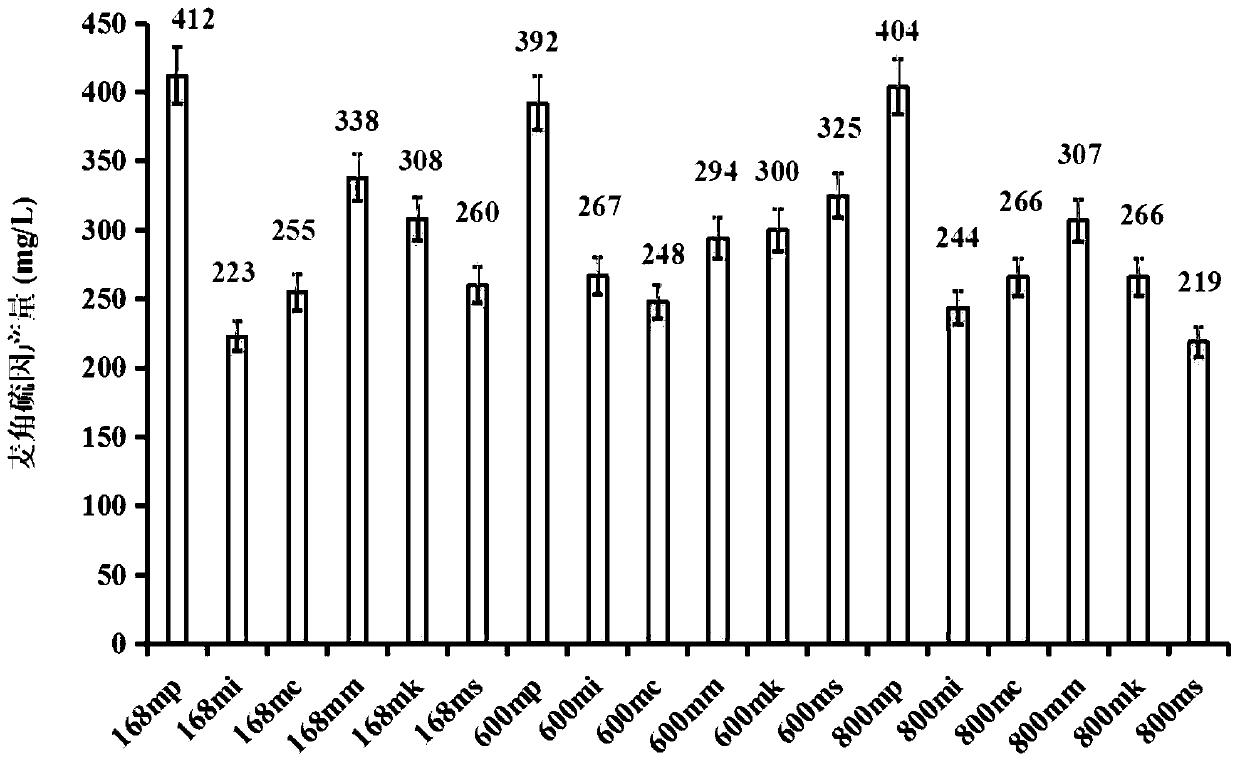

Embodiment 3

[0049] Example 3 Shake flask culture and ergothioneine content determination of Escherichia coli and Bacillus subtilis recombinant bacteria expressed in different combinations of genes contained in the egtABCDE gene cluster

[0050] Select Escherichia coli, Bacillus subtilis recombinant bacteria and control bacteria (transformed with pEBS empty plasmid) with optimized expression of different combinations of genes contained in the egtABCDE gene cluster constructed above and inoculate them in 5 mL LB medium, and add a final concentration of 50 μg as needed / mL kanamycin, cultured at 200rpm 37°C for 10-12h, and then transferred to a 250mL Erlenmeyer shaker flask with 10% inoculum size. Kanamycin with a final concentration of 50 μg / mL was then placed at 220 rpm and cultured at 37°C. Added methionine, histidine betaine, histidine, cysteine, and added methylthio The final concentration of amino acid is 8g / L, the final concentration of added histidine betaine is 15g / L, the final conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com