Universal industrial glue and preparation method thereof

An industrial glue, general-purpose technology, used in adhesive types, monocarboxylic acid ester copolymer adhesives, adhesive additives, etc., can solve the problems of high price, unusability, freezing, etc., and achieve low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a general-purpose industrial glue, including the following raw materials in parts by weight: 40 parts of polyvinyl alcohol, 3 parts of formaldehyde, 2 parts of hydrochloric acid, 6 parts of sodium hydroxide, 2 parts of chain integrity agent, 400 parts of water, Vinyl acetate 3000 parts, OP-104 parts, dibutyl phthalate 36 parts, potassium persulfate 0.2 parts.

[0036] Preferably, the polyvinyl alcohol is 1799 type.

[0037] Preferably, the OP-10 is a nonionic surfactant alkylphenol polyoxyethylene ether.

Embodiment 2

[0039] The difference between this embodiment and Example 1 is that it includes the following raw materials in parts by weight: 45 parts of polyvinyl alcohol, 4 parts of formaldehyde, 3.5 parts of hydrochloric acid, 7 parts of sodium hydroxide, 2 parts of chain integrity agent, 500 parts of water, acetic acid Vinyl ester 360 parts, OP-105 parts, dibutyl phthalate 37.5 parts, potassium persulfate 0.6 parts.

Embodiment 3

[0041] The difference between this embodiment and Example 1 is that it includes the following raw materials in parts by weight: 40-50 parts of polyvinyl alcohol, 5 parts of formaldehyde, 5 parts of hydrochloric acid, 9 parts of sodium hydroxide, 2 parts of chain-integrating agent, 600 parts of water , 420 parts of vinyl acetate, 106 parts of OP-106 parts, 39 parts of dibutyl phthalate, and 0.8 parts of potassium persulfate.

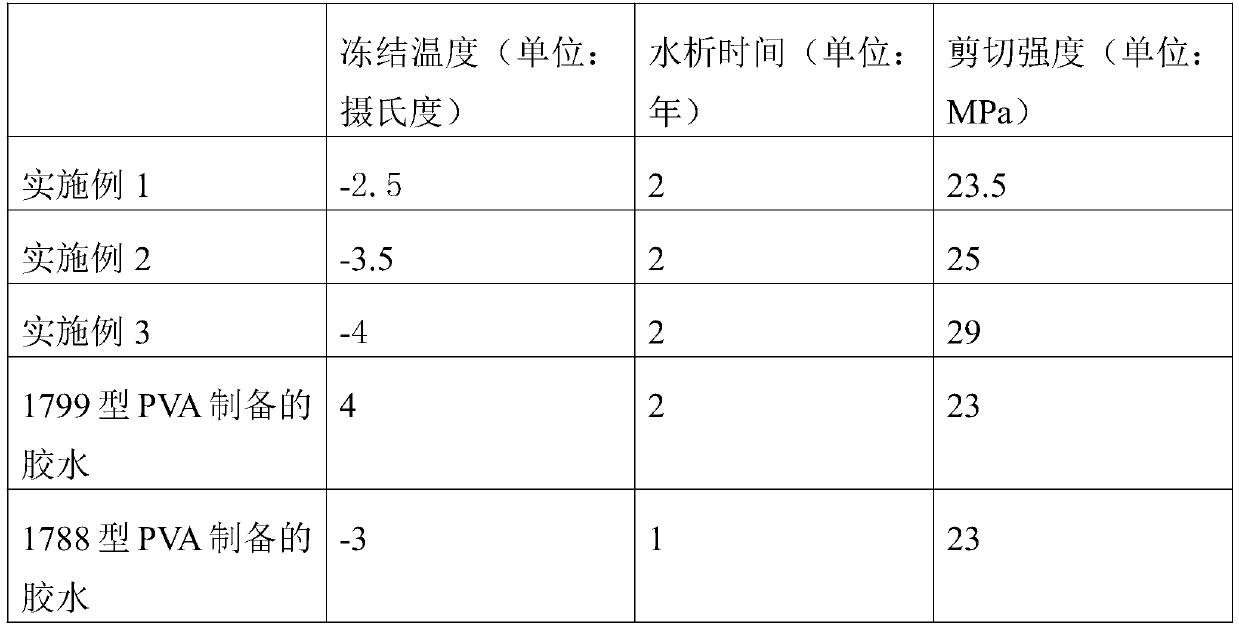

[0042] Carry out experimental comparison with traditional glue according to above-mentioned embodiment, concrete comparative data is as table 1:

[0043]

[0044] Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com