Method for preparing mesophase carbon microspheres by using emulsification-hydrogenation-thermal polymerization ternary coupling system

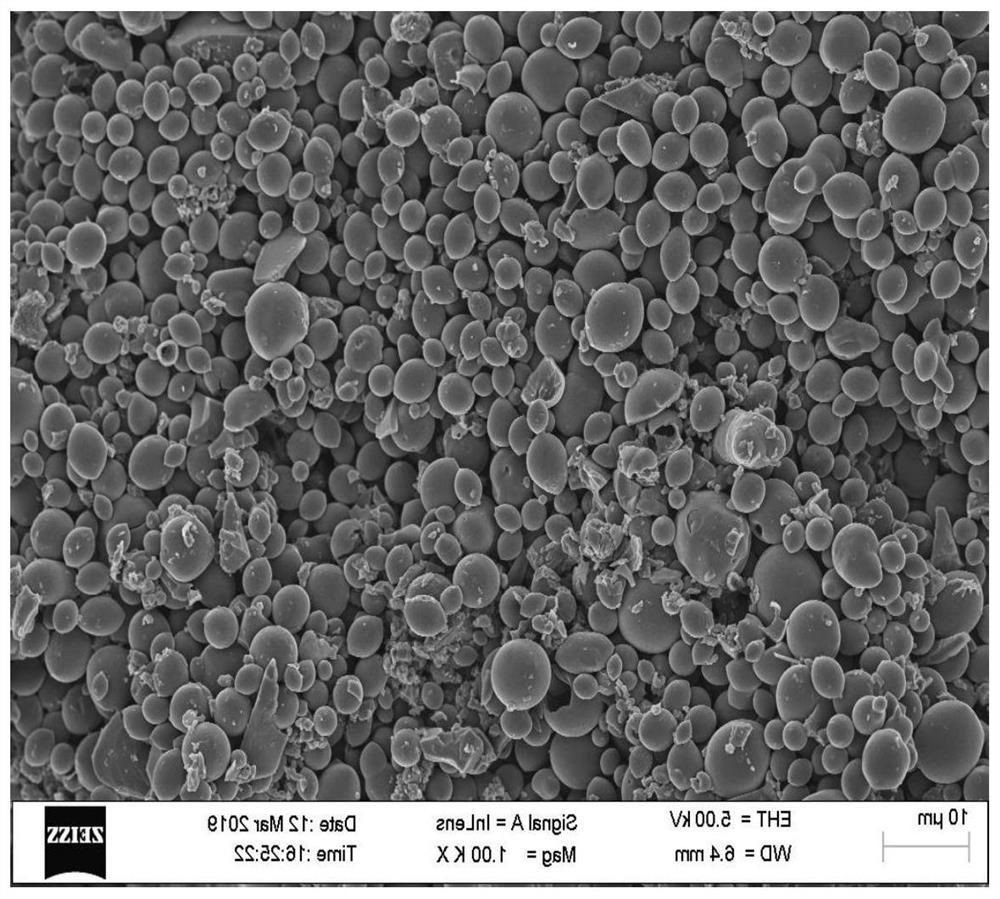

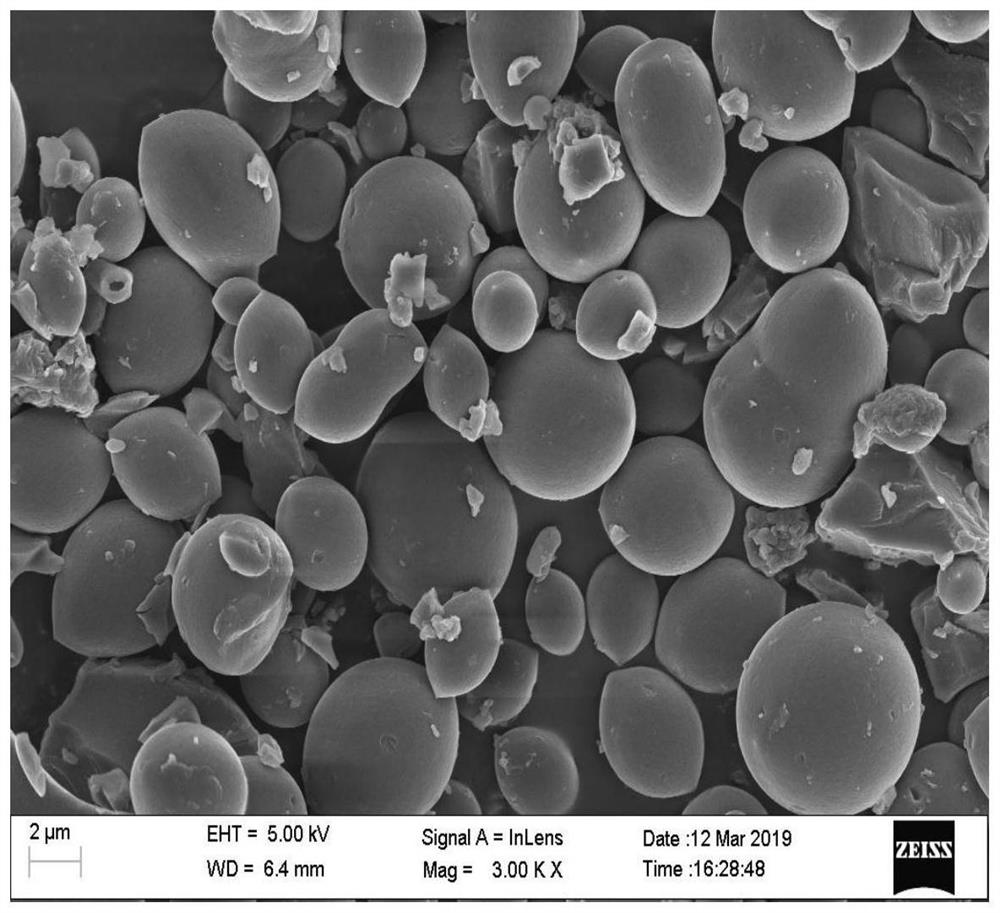

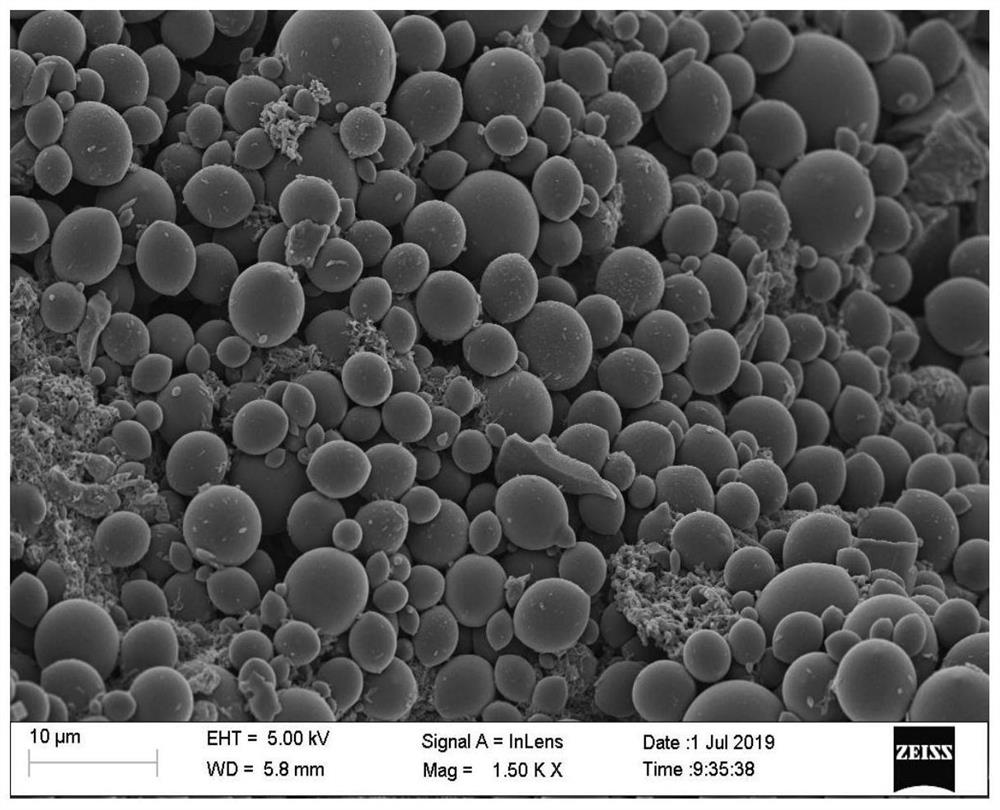

A mesophase carbon microsphere and thermal polymerization technology, which is applied in the preparation/purification of carbon, can solve the problems of unsatisfactory degree of graphitization and complicated process, and achieve good sphericity, uniform particle size distribution and uniform particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The method for preparing mesophase carbon microspheres in this embodiment is specifically:

[0043] (1) According to the added amount of hydrogen donating solvent is 15.00wt%, the added amount of modified catalyst is 0.05wt%, and the added amount of emulsified solvent is 84.95wt%, and mixed to prepare emulsified-hydrogenation-thermal polymerization three-way coupling solvent system, wherein , the mass ratio of the modified catalyst is blue coke:coke:graphene:modifier=80:10:5:5.

[0044] (2) Put 2.5kg of medium and low temperature coal tar in a rectification kettle for distillation, and distill out soft asphalt with a distillate section at 330-420°C, with a softening point of 40 and an aromaticity of 0.4, according to soft asphalt: three-way coupling Solvent system = 1:3 ratio mixing, placed in a high-pressure reactor for three-stage heating reaction, that is, the first stage is dominated by emulsification and dispersion, rising from normal temperature to 220°C, constant...

Embodiment 2

[0048] The method for preparing mesophase carbon microspheres in this embodiment is specifically:

[0049] (1) According to the added amount of hydrogen-donating solvent is 12.00wt%, the added amount of modified catalyst is 0.5wt%, and the emulsified solvent is added to 100%, and mixed to prepare an emulsified-hydrogenation-thermal polymerization three-way coupled solvent system, wherein, modified The mass ratio of the active catalyst is blue carbon: coke: graphene: modifier = 75:5:15:5.

[0050] (2) Put 2.5kg of medium and low temperature coal tar in a rectification kettle for distillation, and distill out soft asphalt with a distillate section at 330-420°C, with a softening point of 40 and an aromaticity of 0.4, according to soft asphalt: three-way coupling Solvent system = 1:4 ratio mixing, placed in a high-pressure reactor for three-stage heating reaction, that is, the first stage is dominated by emulsification and dispersion, from normal temperature to 200 ° C, constant t...

Embodiment 3

[0054] The method for preparing mesophase carbon microspheres in this embodiment is specifically:

[0055] (1) According to the added amount of hydrogen-donating solvent is 10.00wt%, the added amount of modified catalyst is 0.01wt%, and the emulsified solvent is added to 100%, and mixed to prepare an emulsified-hydrogenation-thermal polymerization three-way coupled solvent system, wherein, modified The mass ratio of the active catalyst is blue carbon:coke:graphene:modifier=88.9:10:1:0.1.

[0056] (2) Put 2.5kg of medium and low temperature coal tar in a rectification kettle for distillation, and distill out soft asphalt with a distillate section at 330-420°C, with a softening point of 70 and an aromaticity of 0.5, according to soft asphalt: three-way coupling Solvent system = 1:5 ratio mixing, placed in a high-pressure reactor for three-stage heating reaction, that is, the first stage is dominated by emulsification and dispersion, rising from normal temperature to 250°C, const...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com