Push-pull rolling device for auxiliary rebar connection

A technology of rolling device and steel bar, which is applied in the field of push-pull rolling device, can solve the problems such as rotation and axial movement of semi-finished steel bar, and achieve the effect of improving mechanical installation efficiency, improving steel bar quality and finished product quality, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

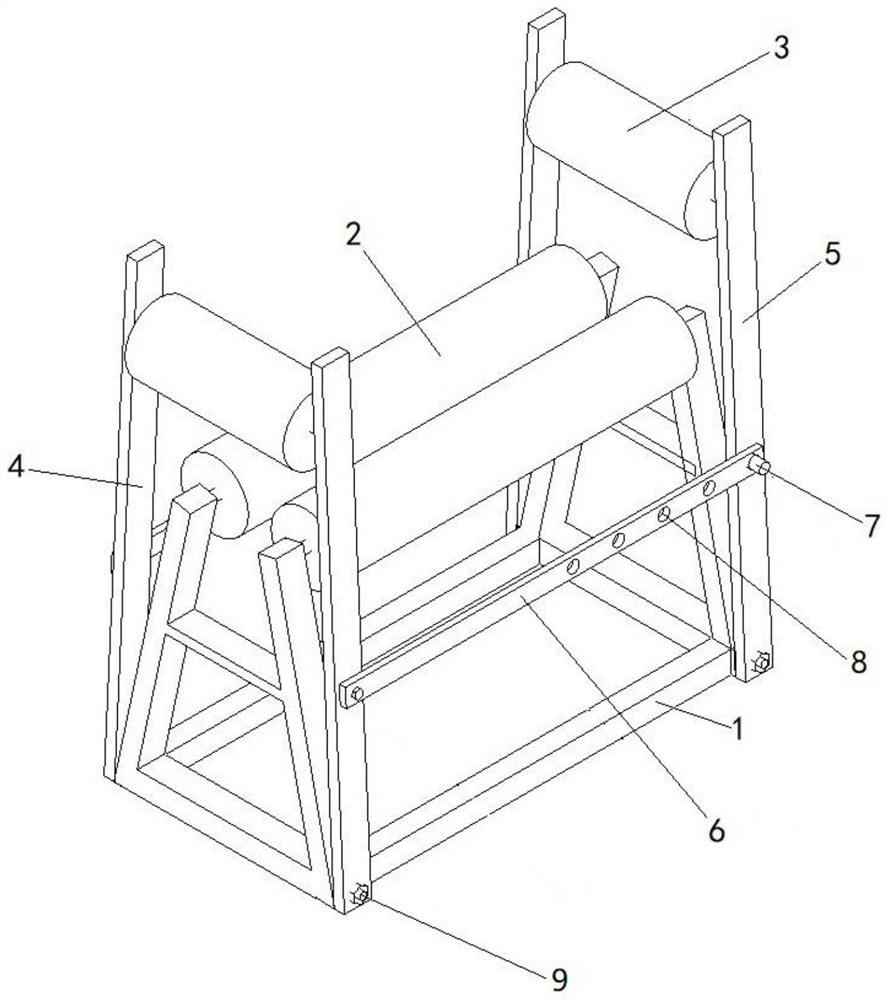

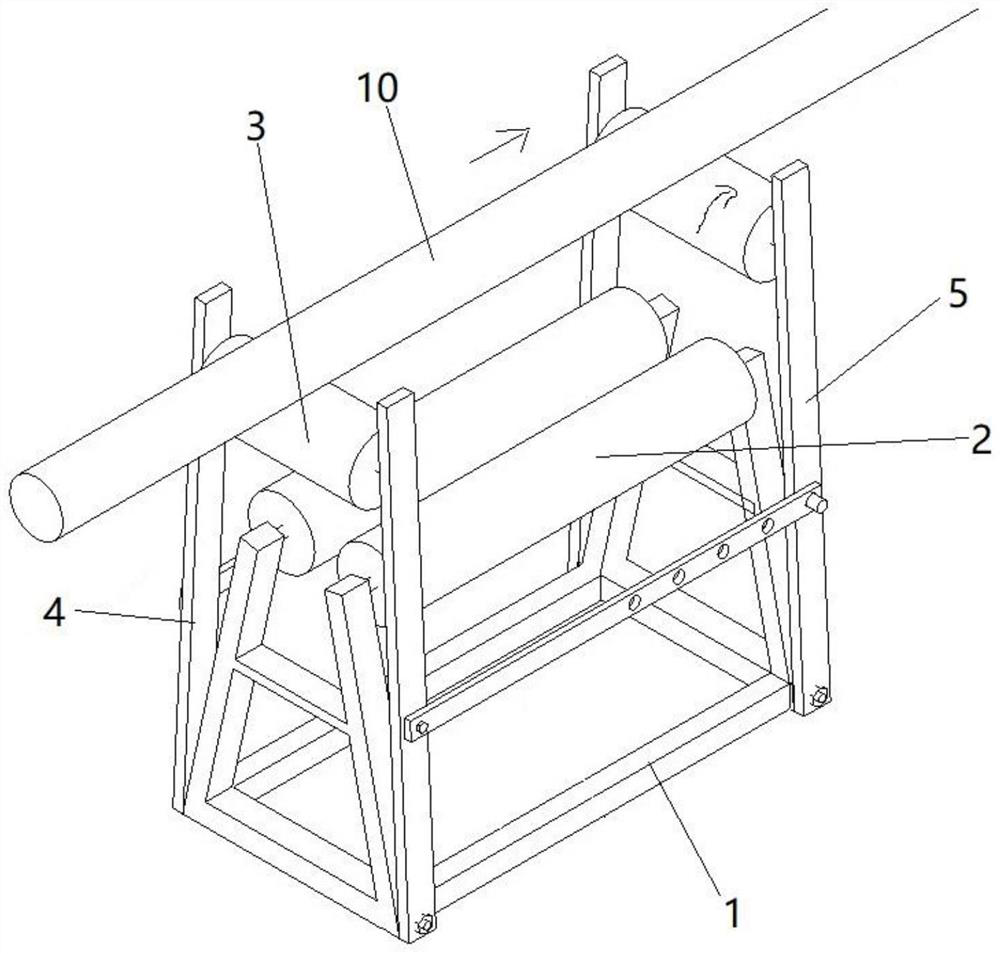

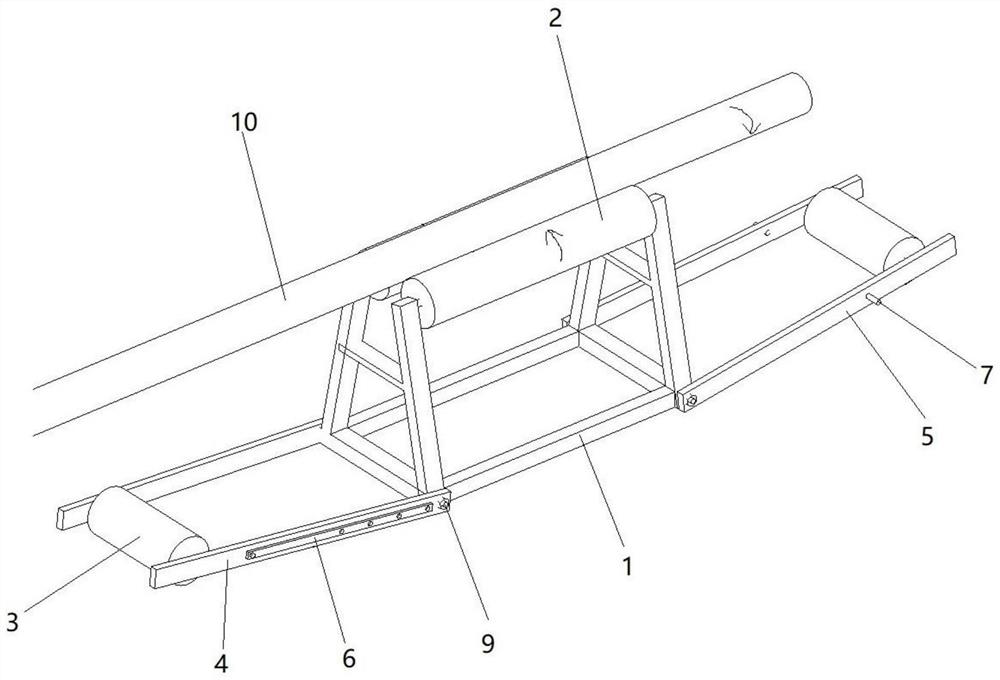

[0022] Such as figure 1 As shown, the push-pull rolling device for auxiliary steel bar connection of the present invention includes a base 1 , a first rotating bracket 4 , a second rotating bracket 5 and a horizontal tie rod 6 .

[0023] The top of the base 1 is provided with two rotating guide wheels 2, the left and right sides of the base 1 are respectively provided with a first rotating bracket 4 and a second rotating bracket 5, and the first rotating bracket 4 and the second rotating bracket 5 are provided with push-pull guide wheels 3 , the push-pull guide wheel 3 is located above the rotating guide wheel 2, and the axis of the push-pull guide wheel 3 is perpendicular to the axis of the rotating guide wheel 2.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com