Flexible positioning bracket for coating and automatic feeding and discharge of exterior trimming parts

A technology of flexible positioning and exterior decoration, which is applied in the direction of spraying devices, etc., can solve the problem of a large number of personnel, and achieve the effect of meeting the requirements of unmanned operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

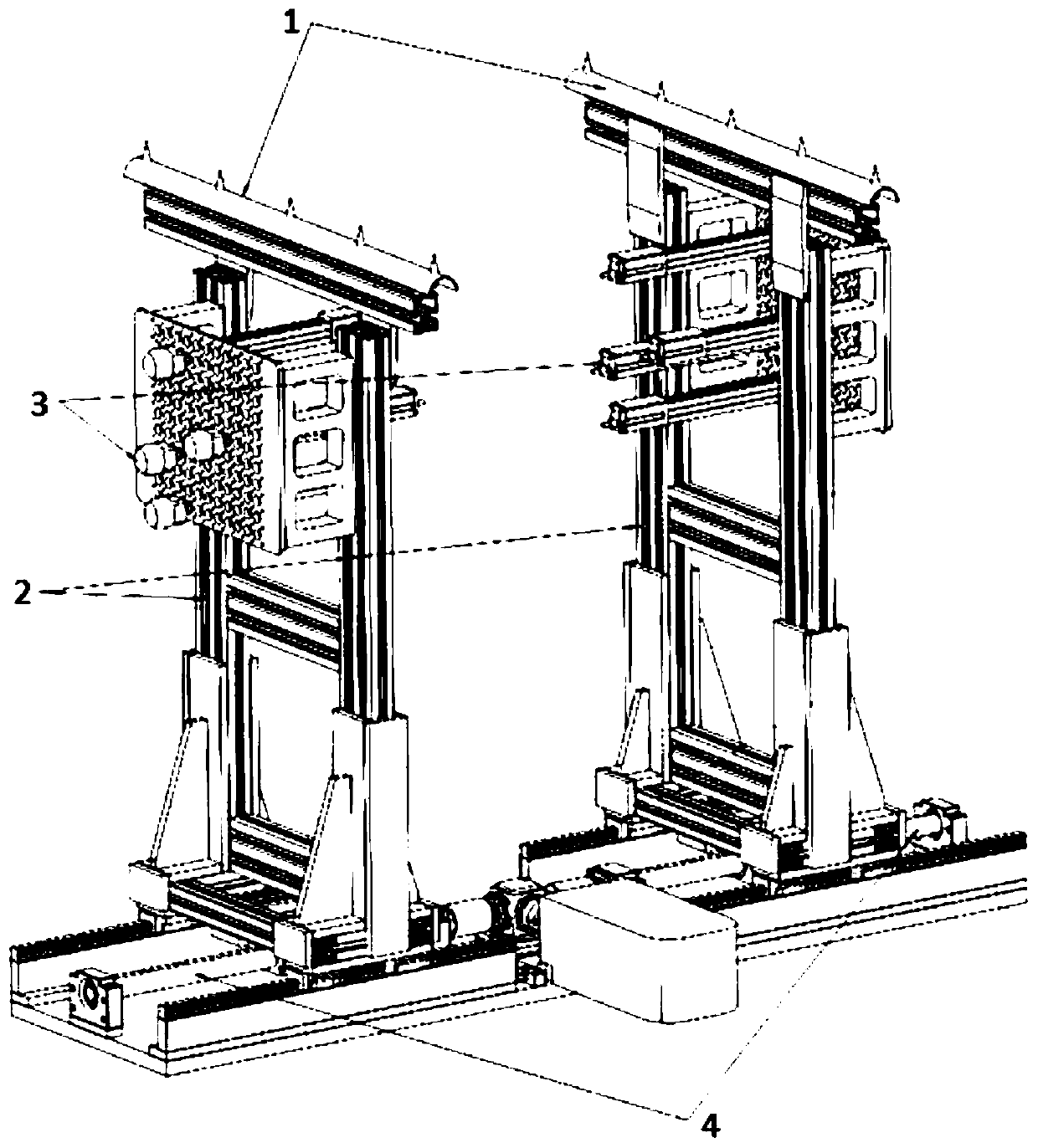

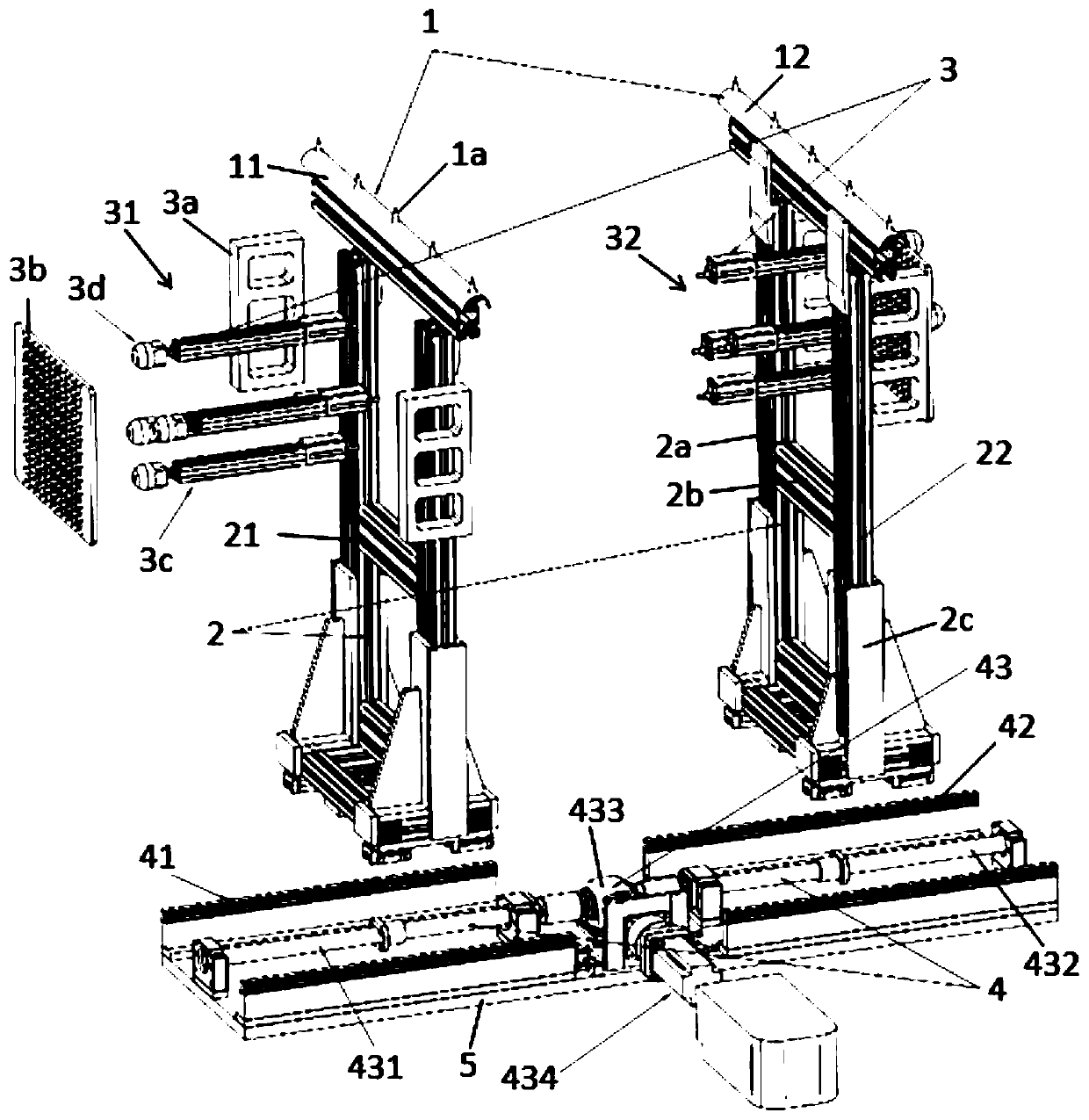

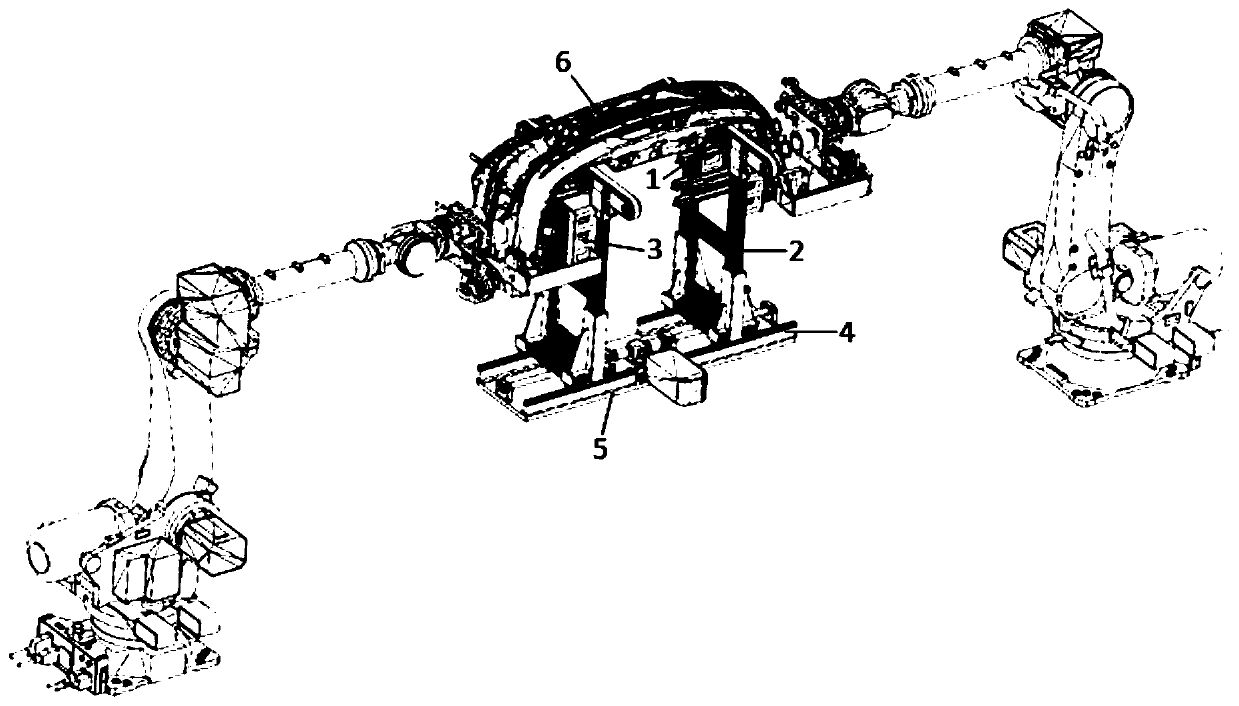

[0021] Such as Figure 1-Figure 2 As shown, according to a preferred embodiment of the present invention, the flexible positioning bracket for automatic loading and unloading of exterior trim parts includes a supporting positioning mechanism 1, a vertical frame mechanism 2, a pushing mechanism 3 and a driving mechanism 4, wherein the vertical The frame mechanism 2 is movably installed on the driving mechanism 4 to move in the left and right directions under the action of the driving mechanism 4, and the supporting and positioning mechanism 1 is fixedly installed on the vertical frame mechanism 2 to support and position the exterior trim , The top extension mechanism 3 is telescopically installed on the vertical frame mechanism 2 for flexible positioning of the exterior trim.

[0022] The support positioning mechanism 1 is a set of left and right a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com