Medicine plate baiting mechanism of box packing machine

A technology of cartoning machine and medicine plate, which is applied in the direction of packaging, can solve the problems of no discovery, etc., and achieve the effect of simple mechanism, convenient feeding and unmanned operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

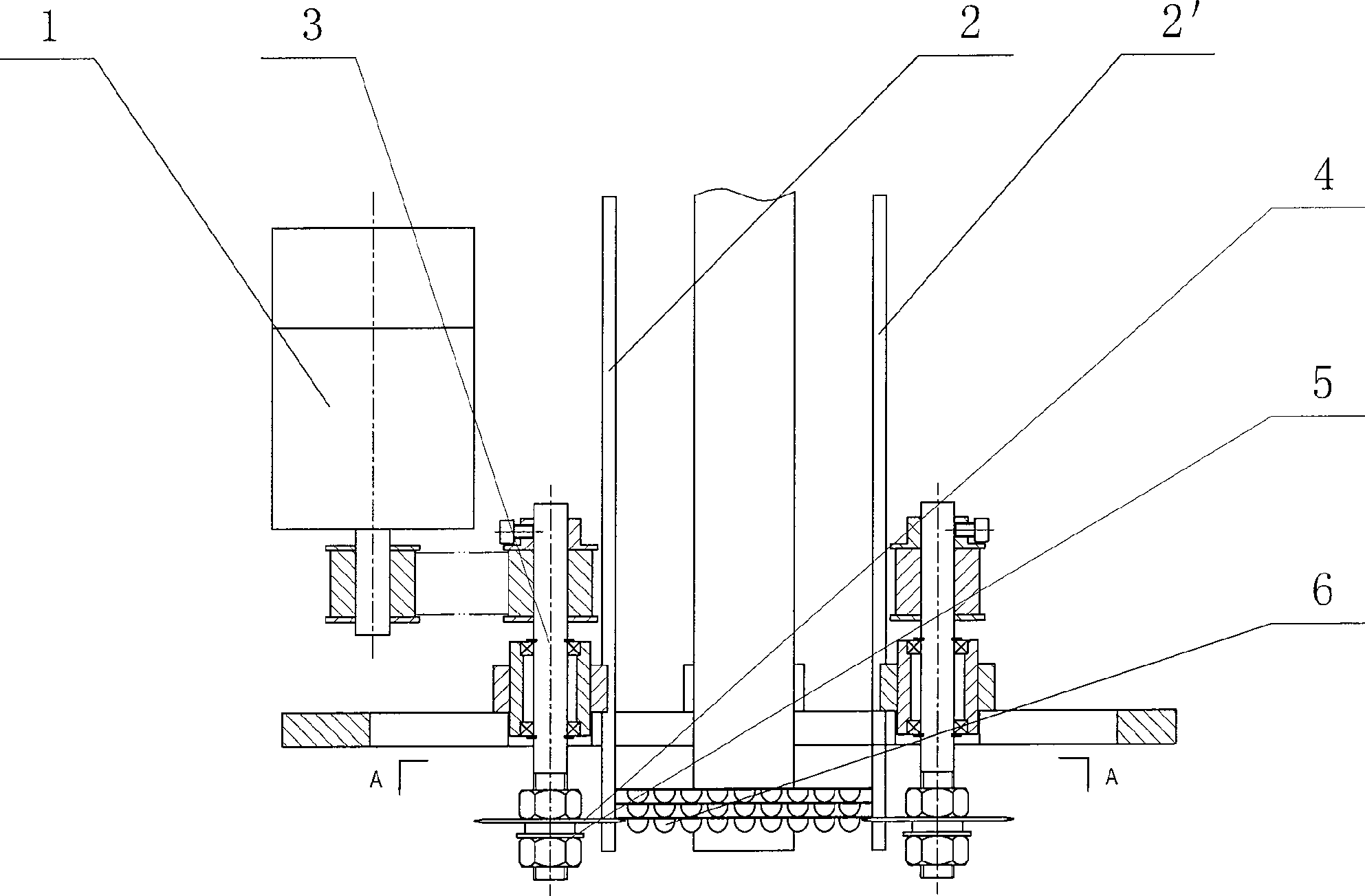

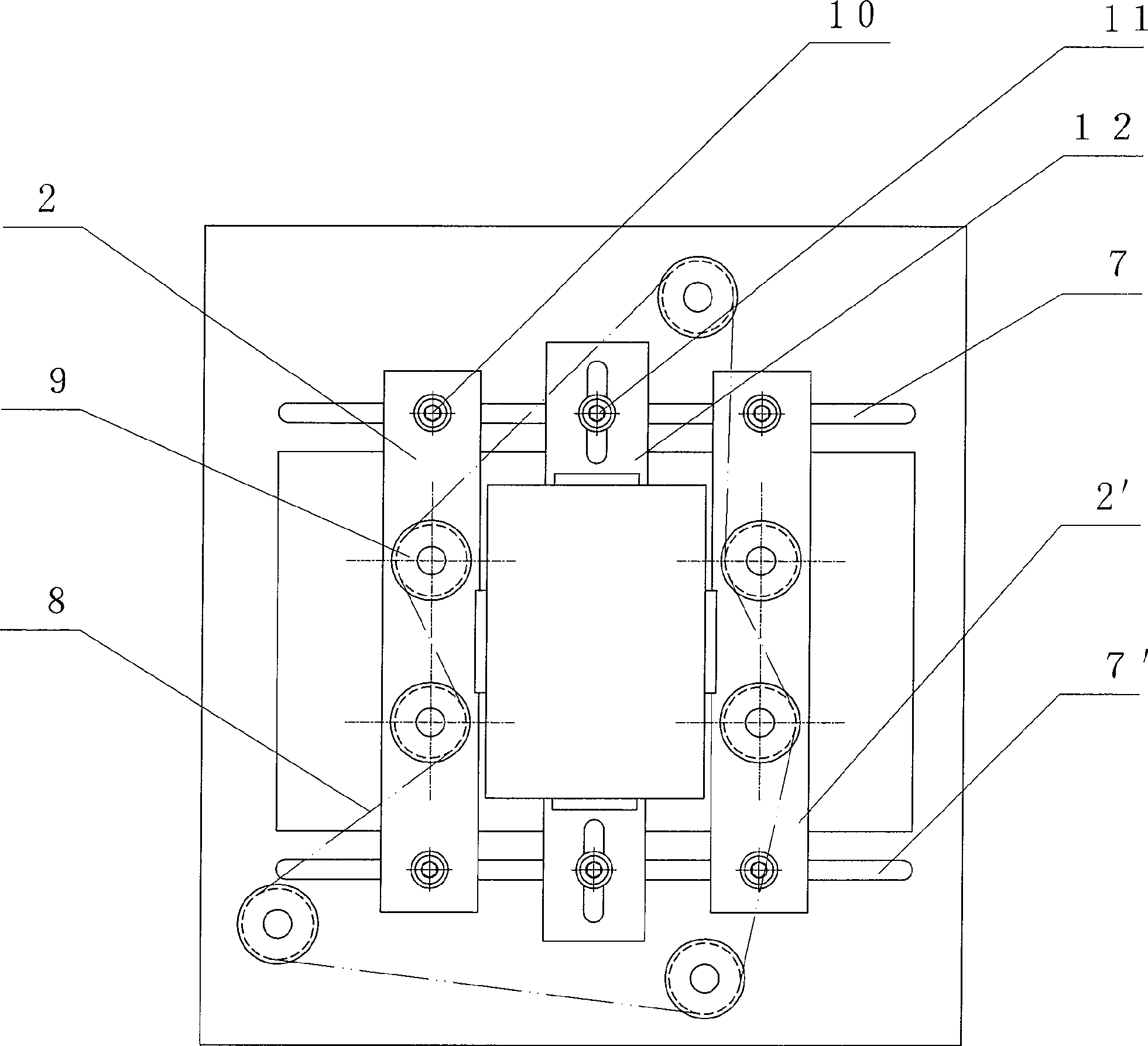

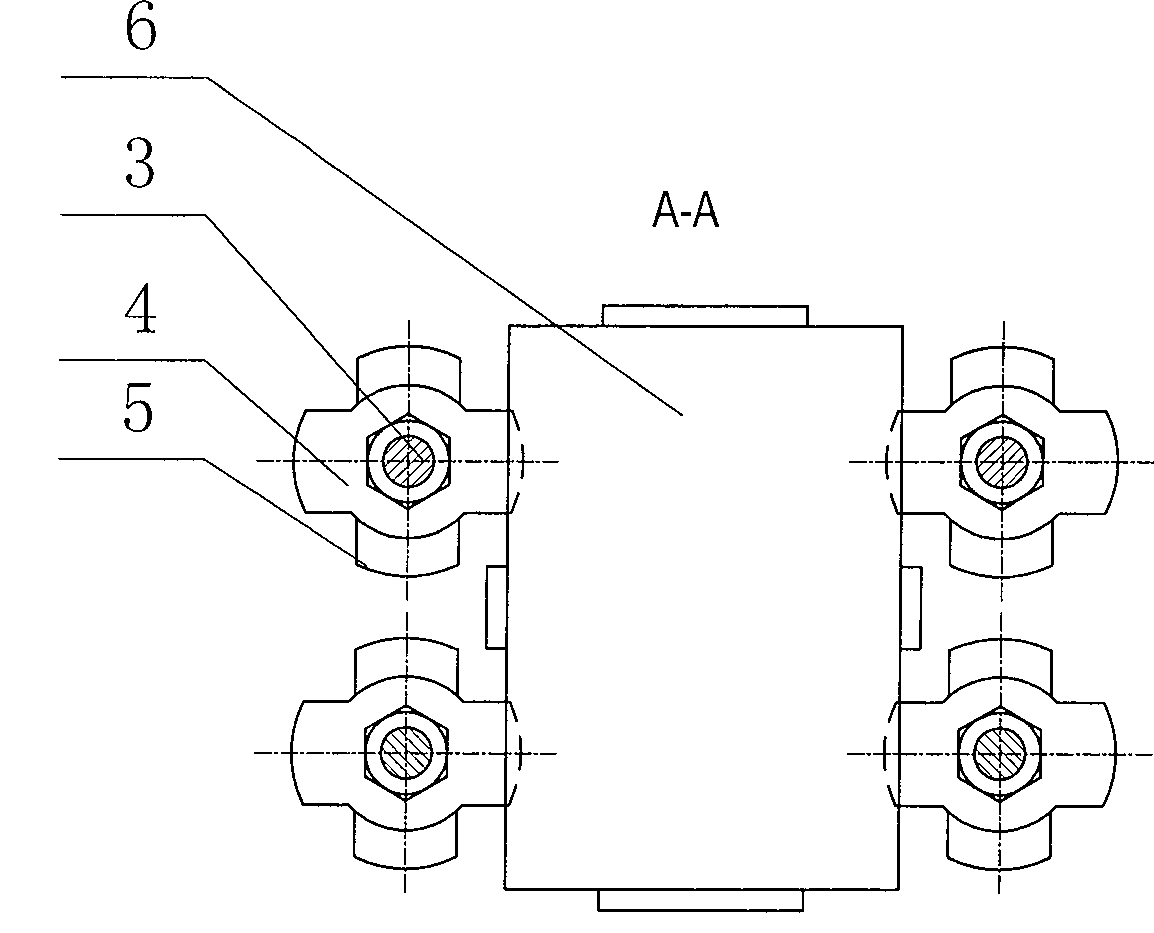

[0010] As shown in the figure, the drug plate blanking mechanism of the cartoning machine includes a motor 1 and a material warehouse. The motor adopts a servo motor and is electrically connected to a programmable controller, and the programmable controller is used to control the servo motor. The material storehouse is composed of upper, lower, left and right adjustment plates, and two upper baffles 4 and lower baffles 5 are respectively installed on the left and right adjustment plates 2, 2', the upper baffles 4 and the lower baffles Baffle plate 5 is fixed on the same rotating shaft 3, and is " ten " character setting, and the distance of upper baffle plate 4 and lower baffle plate 5 should be greater than the thickness of medicine plate 6, and synchronous wheel 9 is installed on one of them rotating shaft 3, and this synchronous The wheel 9 is connected to the rotating shaft of the motor 1 through the synchronous belt 8. The synchronous wheel 9 is also installed on the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com