A Method for Dividing Complex Process Modules Oriented to Mass Customization

A process module, large-scale technology, applied in the field of complex process module division, can solve the problems of not integrating individual requirements, inappropriate process modules, etc., to achieve the effect of perfect process, tight logic, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

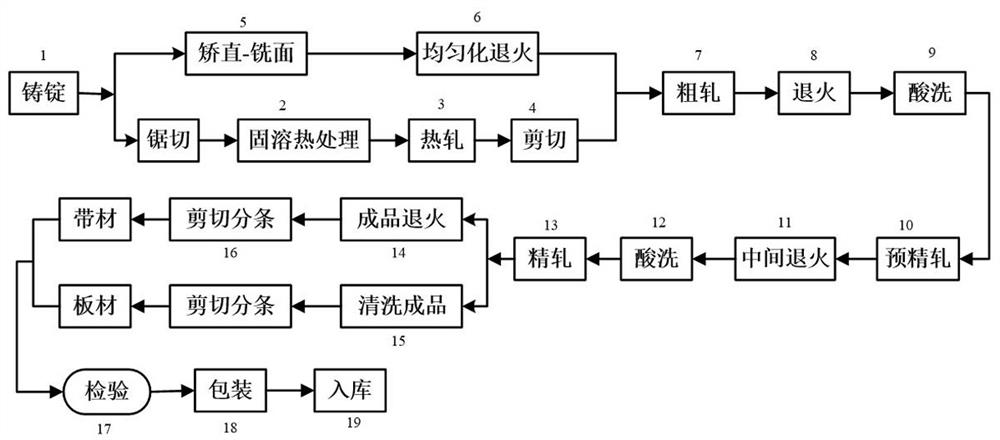

[0037] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

[0038] A method for dividing complex process modules for mass customization, comprising the following steps:

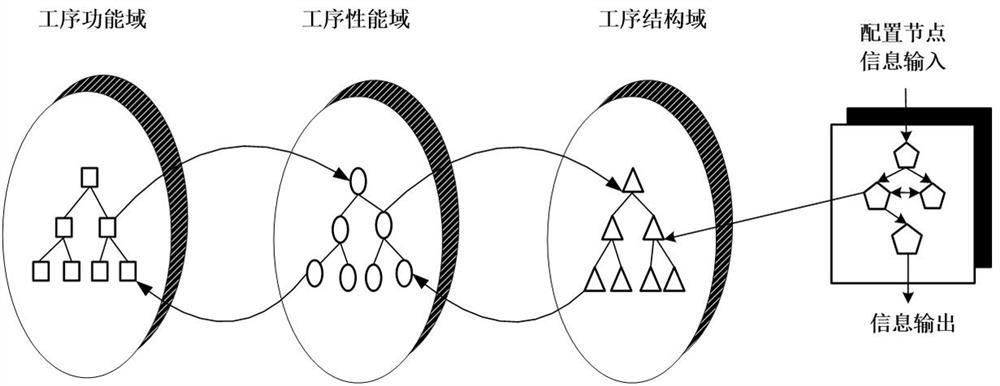

[0039] S1: The module characteristic attribute is established by the modular mapping mechanism, and the correlation between the process modules is established by the attribute, and the correlation is described as replaceable correlation and influence correlation;

[0040] S2: The degree of interrelationship between process modules is related to the replaceability characteristics and influence degree correlation, and is expressed by the mathematical model of fuzzy correlation matrix R: R=ω f F+ω p P;

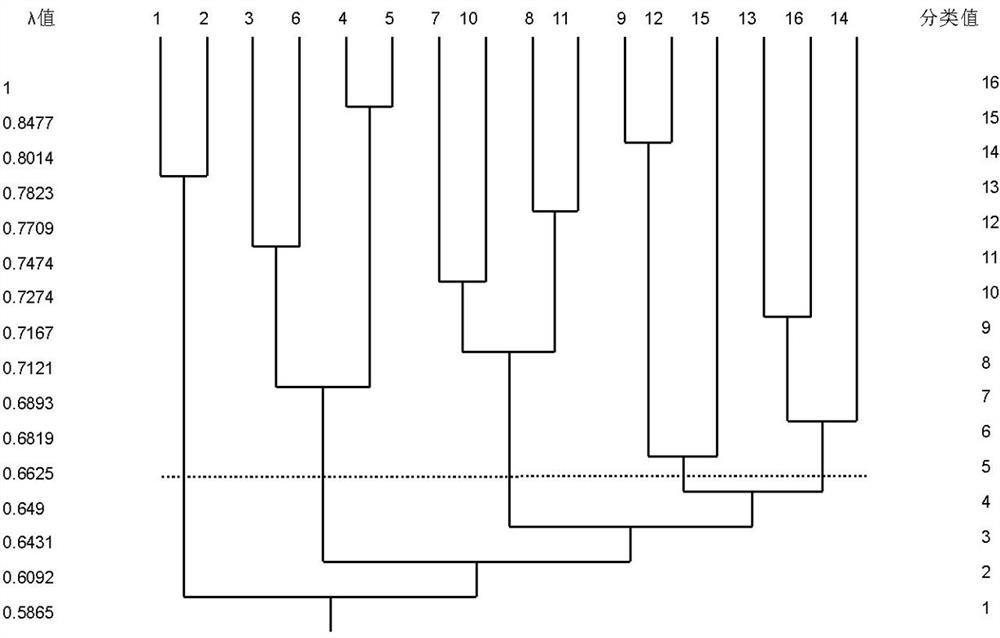

[0041] S3: Using...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com