Automatic loading and unloading checking device of electronic belt weigher

An electronic belt scale and automatic loading technology, applied in the direction of measuring devices, weighing equipment testing/calibration, instruments, etc., can solve problems such as low stability and reliability, calibration and correction, and increase safety hazards, etc., to improve The level of labor productivity, the effect of ensuring safety and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to specific embodiments and accompanying drawings, but the following embodiments are only preferred embodiments of the present invention, not all of them. . Based on the examples in the implementation manner, other examples obtained by those skilled in the art without creative work shall fall within the protection scope of the present invention.

[0020] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

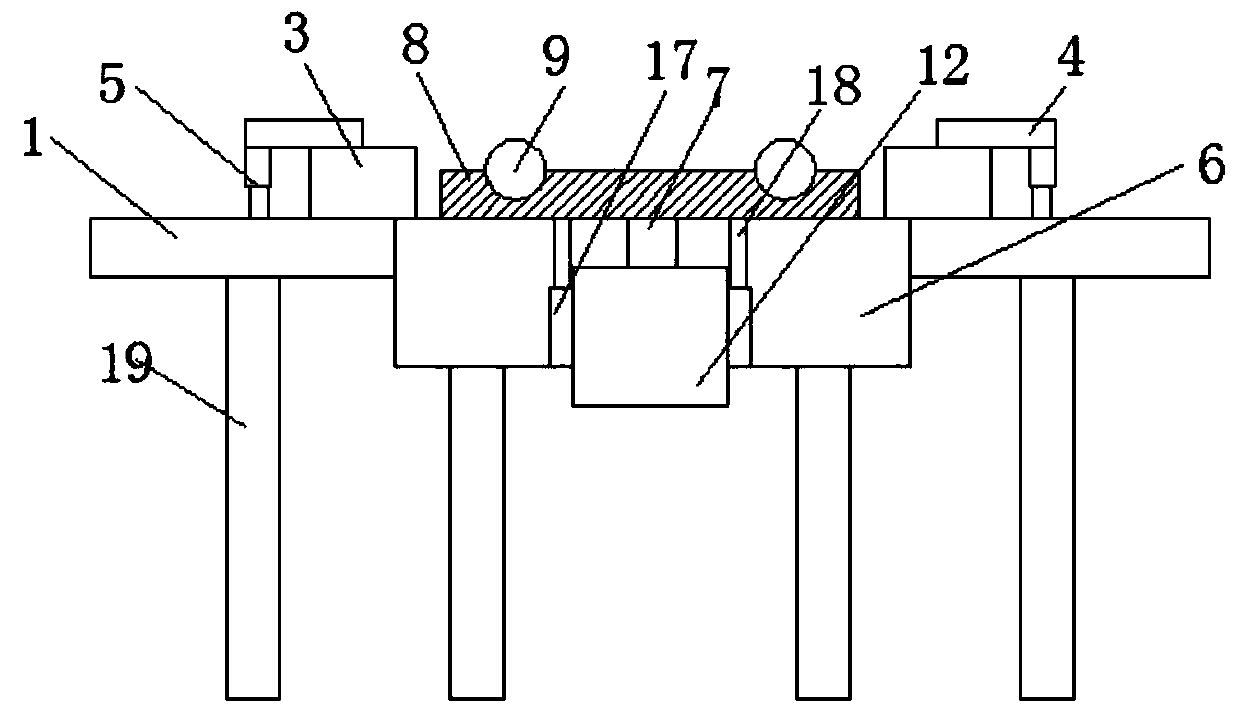

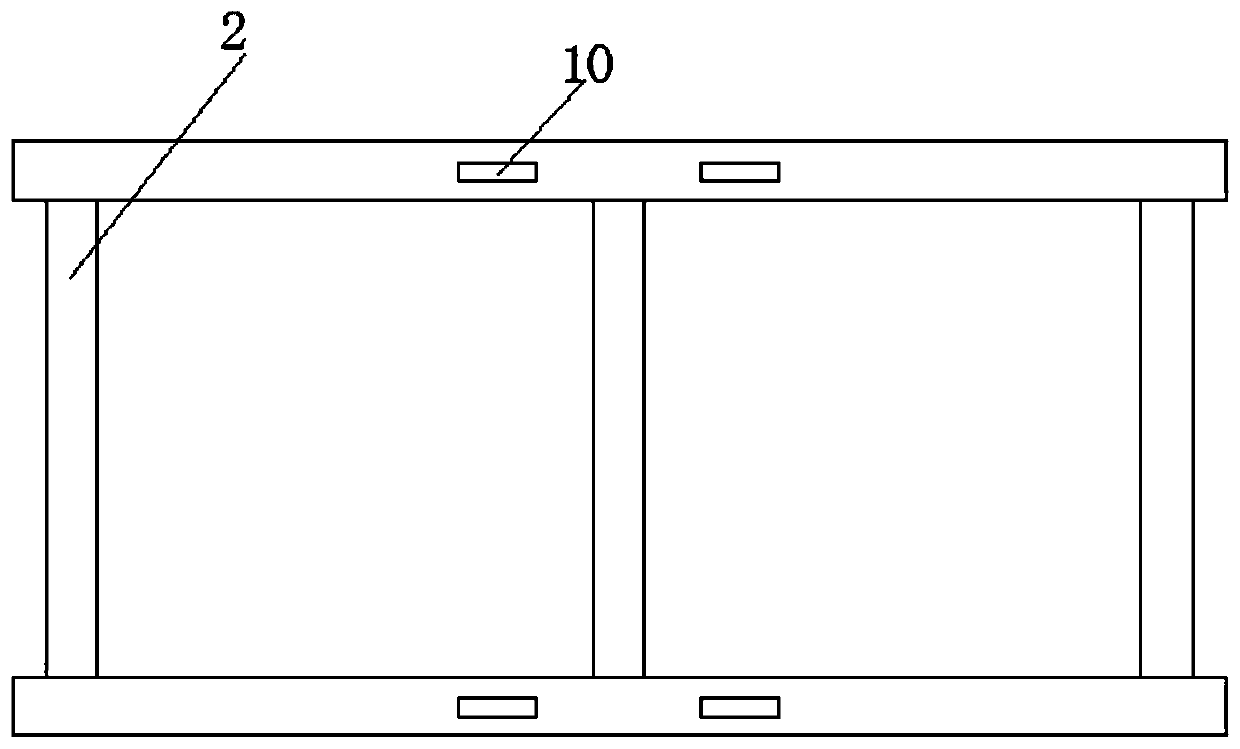

[0021] like Figure 1-5 As shown in the figure, the automatic loading and unloading calibration device of the electronic belt scale includes a base 1 and a scale body weighing frame 2. The upper surface of the base 1 is fixedly connected with two symmetrical scale body fixing frames 3 along the longitudinal ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com