Flow regulating and pressure regulating valve

A pressure regulating valve and flow regulating technology, which is applied in the field of flow regulating and pressure regulating valves, can solve problems such as inability to disassemble and affect the adjustment accuracy of the valve, and achieve the effects of reducing pipeline pressure, reducing the impact of water flow, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

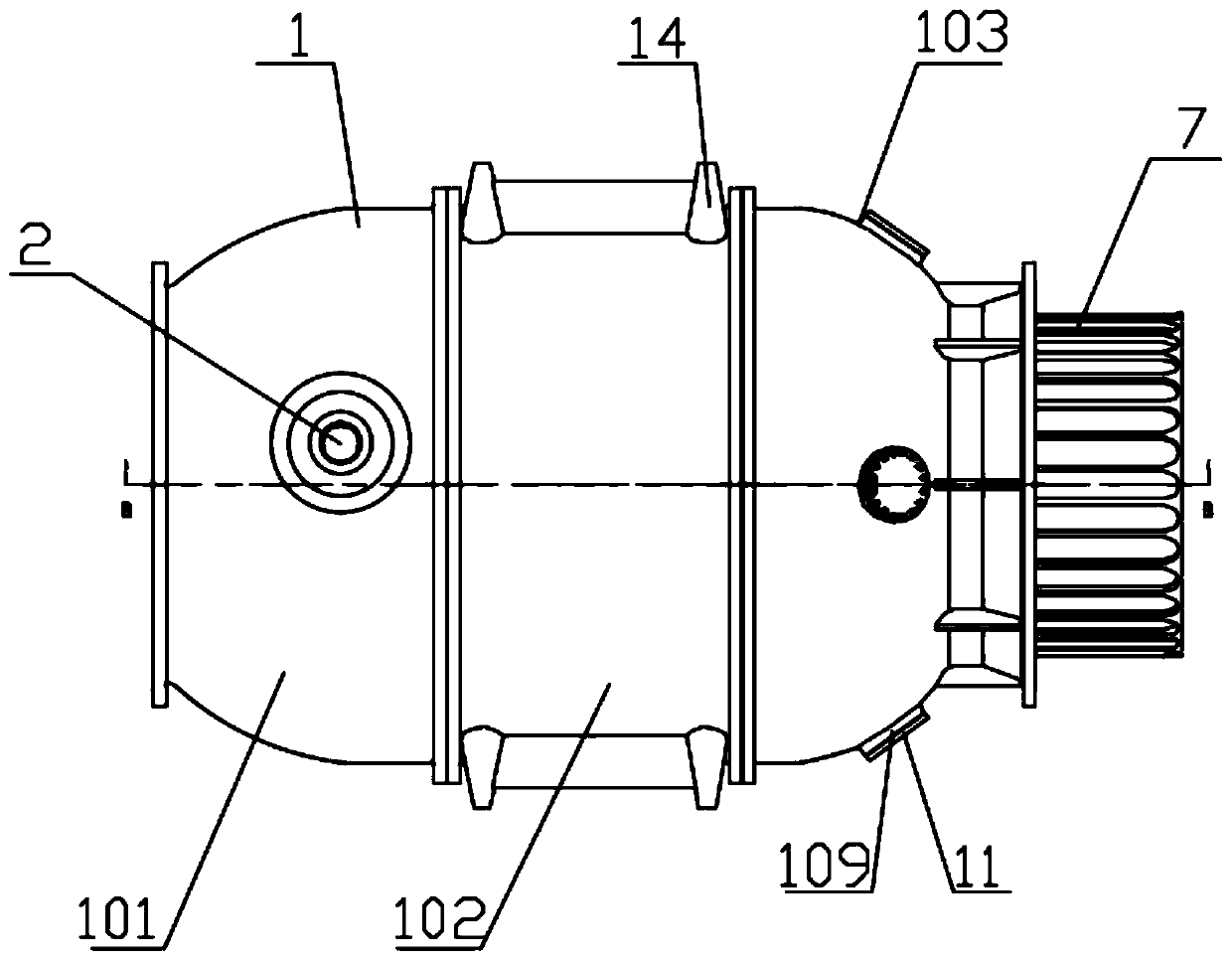

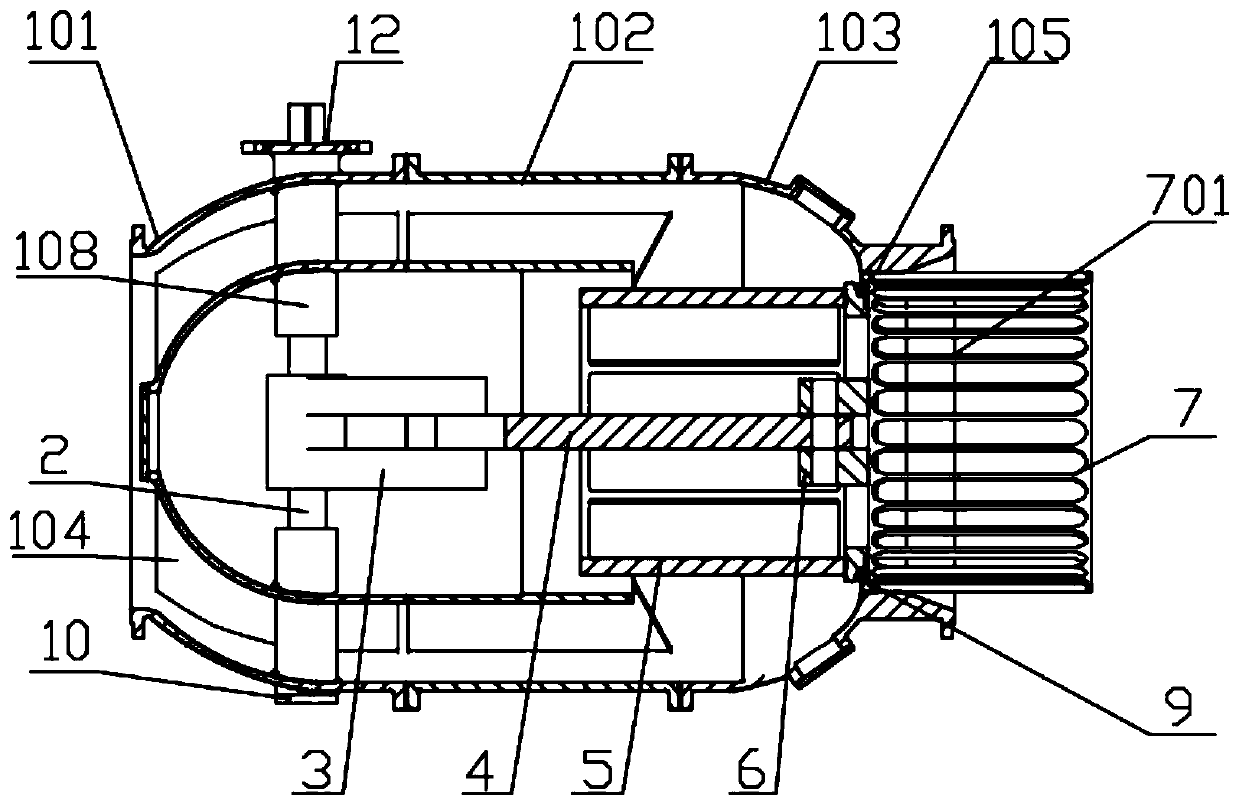

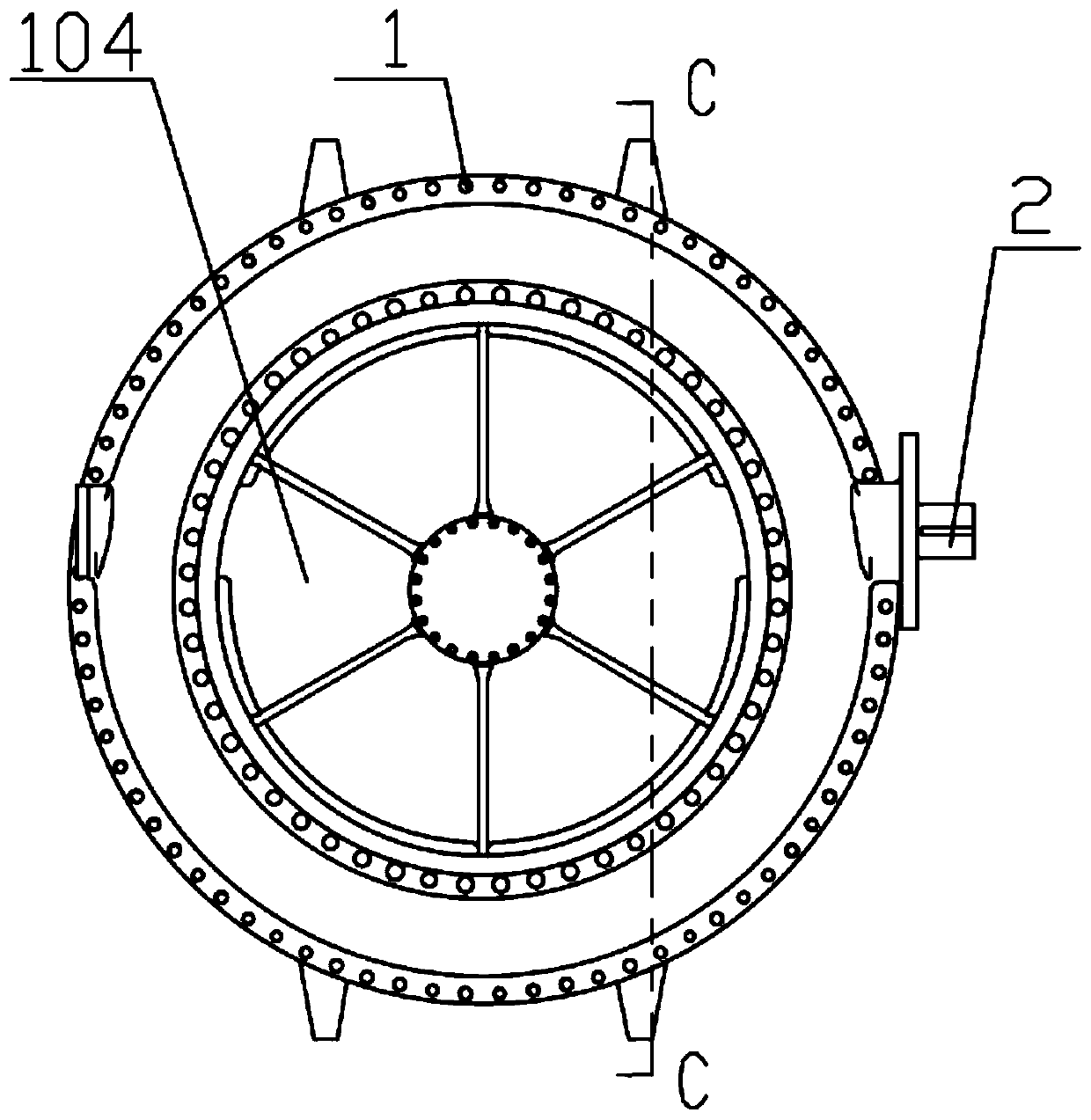

[0041] Embodiment 1: The valve body 1 is sequentially connected and fixed by the left valve body 101 and the right valve body 102 through double stud screws. There is a guide tube 107 inside the valve body 1. The guide tube 107 and the left valve body 101 are integrally connected. The end of the flow tube 107 near the water outlet is an open structure, the water flow channel 106 is between the flow guide tube 107 and the valve body, the left end of the left valve body 101 is the water inlet 104, the right end of the right valve body 102 is the water outlet 105, and the piston 6 is arranged at the outlet. The water outlet 105 is in contact with the water outlet 105. The piston 6 is connected to the rocker arm 3 through the connecting rod. The rocker arm 3 is sleeved on the rotating shaft 2. The rotating shaft 2 controls the piston 6 to move linearly through the driving device. The rotating shaft 2 is located in the water flow channel. 106 places are sheathed in the support sleev...

Embodiment 2

[0042] Embodiment 2: The difference from Embodiment 1 is that the valve body 1 is sequentially connected and fixed by the left valve body 101, the middle valve body 102 and the right valve body 103 through double stud screws. 7 is connected and fixed with the piston 6, and the rotating shaft 2 drives the restrictor cover 7 and the spool 5 to perform linear motion through the rocker arm 3, and the restrictor cover 7 is slidingly connected with the inner wall of the water outlet 105, and plays a role in the movement of the piston 6 and the spool 5. Guiding function, there are flow holes 701 on the flow limiting cover 7, and the flow holes 701 are oblong holes arranged in sequence. The driving device controls the size of the gap between the piston 6 and the water outlet 105 to control the flow of water. Reduce the impact force of water flow and reduce pipeline pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com