Modified type-I collagen, modification method, and collagen gel prepared from modified type-I collagen

A collagen modification technology, applied in the field of medical biomaterials, can solve the problems of complicated operations, low modification efficiency, and the difficulty of avoiding the introduction of exogenous toxic substances, and achieve the effect of increasing the random coil structure and reducing the triple helix structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

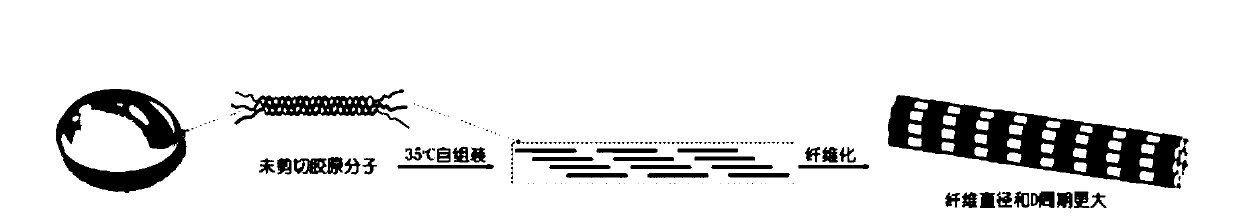

Method used

Image

Examples

Embodiment 1

[0053] At a temperature of 2-10°C, the type I collagen is modified:

[0054] (1) Mix 0.5mol / L acetic acid with bovine Achilles tendon collagen to prepare 2mg / mL acidic collagen solution;

[0055] (2) Dialyzing the acidic collagen solution with phosphate buffer until a neutral collagen solution is obtained, wherein the molecular cut-off of the dialyzed film is 8000-14000;

[0056] (3) Place the neutral collagen solution in a low-temperature centrifuge to remove air bubbles, wherein the centrifuge rotates at 8000 rpm for 10 minutes, and the centrifuge rotor is a fixed-angle rotor with an angle of 30°.

[0057] (4) Under liquid-sealed conditions, use a rotational rheometer to shear the neutral collagen solution from which bubbles have been removed, and leave it to stand after shearing to obtain modified type I collagen;

[0058] Among them, the injection thickness of rotational rheology is 0.6mm, the injection volume is 1.0mL, the diameter of the parallel plate fixture is 4cm, a...

Embodiment 2

[0060] Existing difference with embodiment 1 is: in step (4), neutral collagen solution shear rate is 1000s -1 , the shearing time is 10min.

Embodiment 3

[0062] Existing difference with embodiment 1 is: in step (4), neutral collagen solution shear rate is 2000s -1 , the shearing time is 10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com