Battery-grade iron phosphate alkali-free production method

A production method, iron phosphate technology, applied in the production of hydrogen, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of reducing product costs and high costs, and achieve the effects of reducing costs, avoiding neutralization treatment, and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

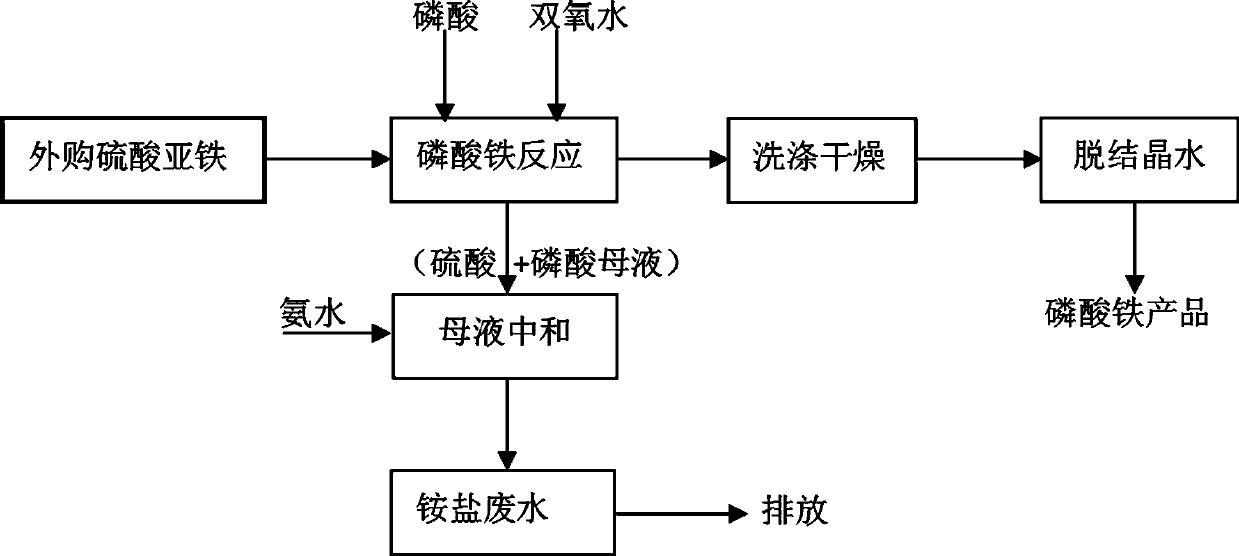

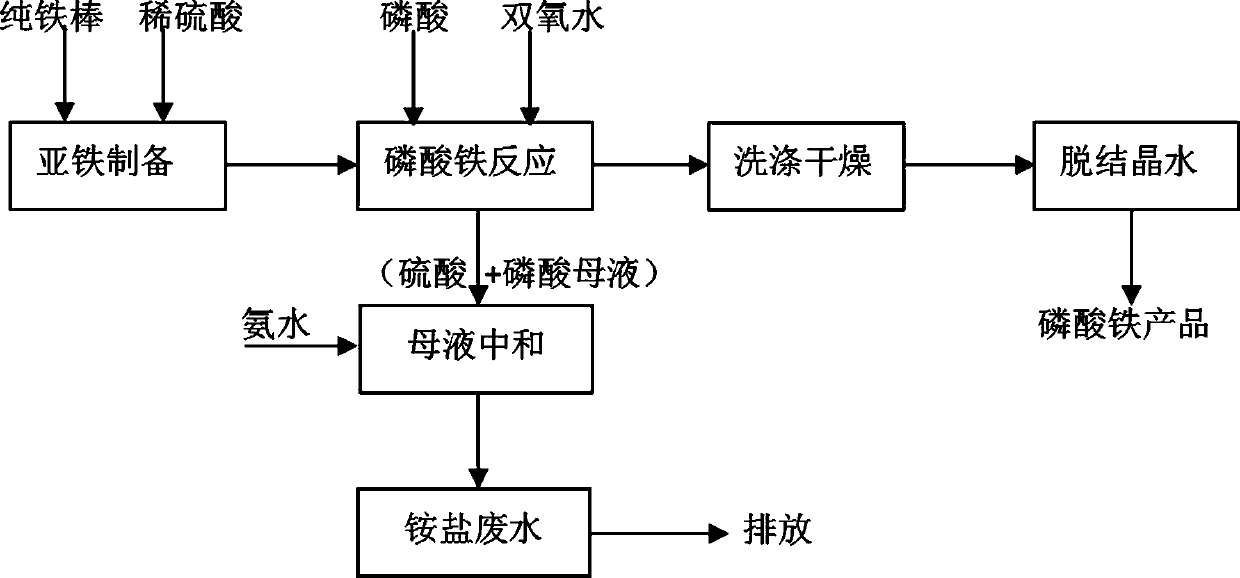

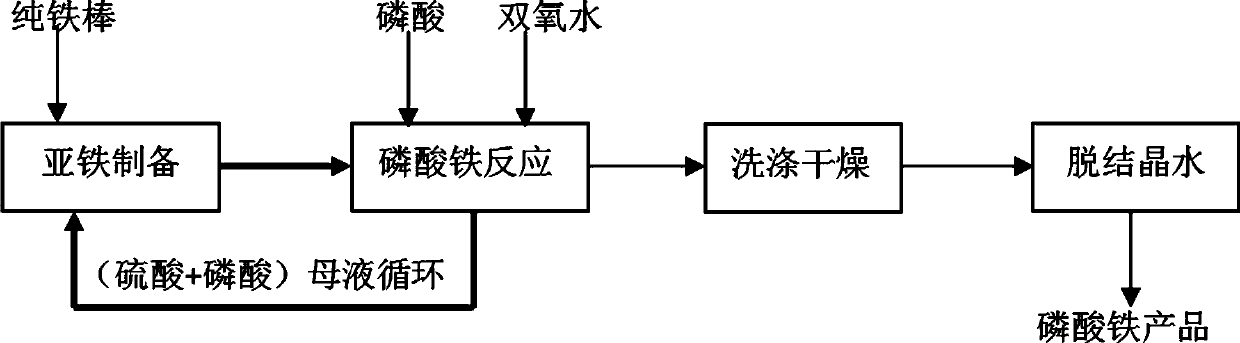

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Example: The production method of the present invention is applied to a 2×5000t / a battery-grade iron phosphate project of a power lithium battery precursor material enterprise. A set of 5000t / a battery-grade ferric phosphate alkali-free production device was put into trial production in November. The approved production capacity of the device technology can reach 5000t / a, and the approved daily production capacity is 15.15t / d. From March 2018 to February 2019 The actual output is about 4868.2t, the average daily output is about 14.75t / d, and the capacity utilization rate of the device during the production period is 97.36%.

[0035] Calculate the comprehensive benefit that the present invention brings to the battery-grade iron phosphate enterprise from three aspects below:

[0036] 1. Calculate the theoretical value of sulfuric acid saving according to the reaction equation

[0037] 2 FeSo 4 + 2H 3 PO 4 + H 2 0 2 = 2 FeP0 4 ·H 2 O↓ + 2 H 2 SO 4

[0038] 304 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com