Sectional type electric logistics vehicle frame structure capable of realizing rapid replacing of power batteries

A power battery and frame structure technology, applied in electric vehicles, substructures, charging stations, etc., can solve the problems of the overall weight of the frame and the long charging time, achieve less welding workload, improve passing performance, reduce vehicle The effect of rack quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

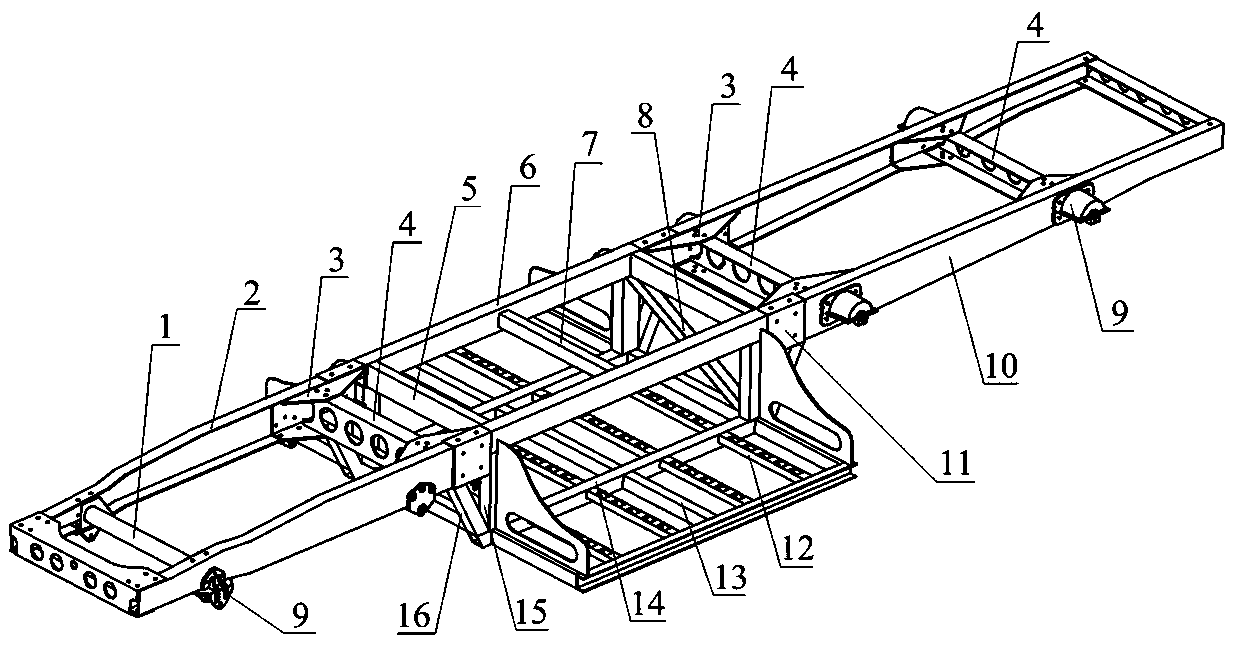

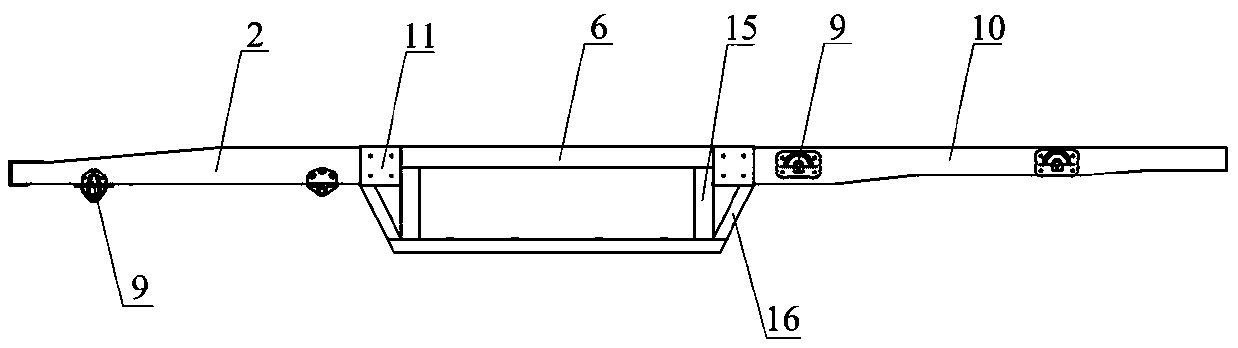

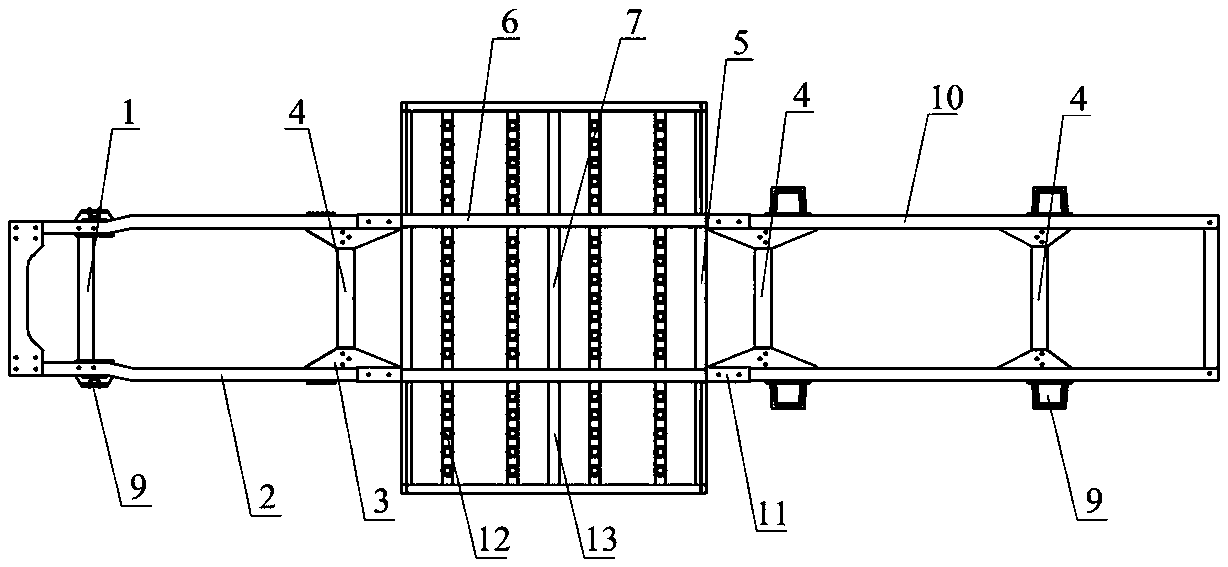

[0029] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

[0030] A frame structure of an electric logistics vehicle capable of quickly replacing power batteries, including a left longitudinal beam, a right longitudinal beam, and a battery pack installation frame structure in the middle of the frame. Both the left and right longitudinal beams include the front longitudinal beam 2, the middle upper The longitudinal beam 6 and the rear longitudinal beam 10, the tubular beam 1 and the connecting beam 4 are connected between the left longitudinal beam and the right longitudinal beam. The middle connecting crossbeam 5, diagonal stay rod 8, vertical vertical beam 15 and diagonal support beam 16, refer to figure 1 , figure 2 , image 3 .

[0031] see figure 1 , figure 2 with image 3 , the section of the front section longitudinal beam 2 and the rear section longitudinal beam 10 of the vehicle frame is groove-shaped,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com