Automatic punching machine and control system thereof

A control system, automatic punching technology, applied in the direction of manufacturing tools, drilling/drilling equipment, metal processing machinery parts, etc. Access and ensure the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

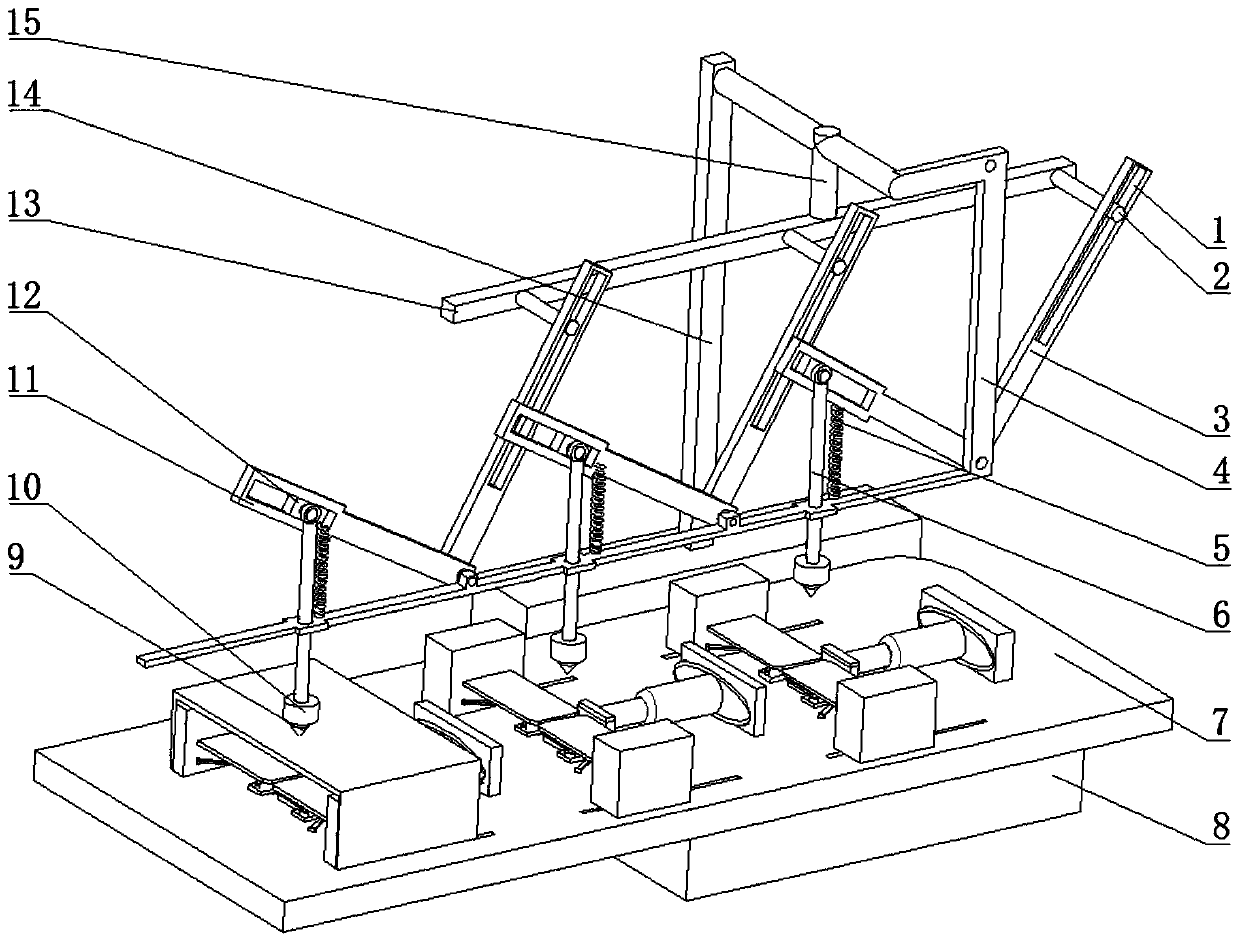

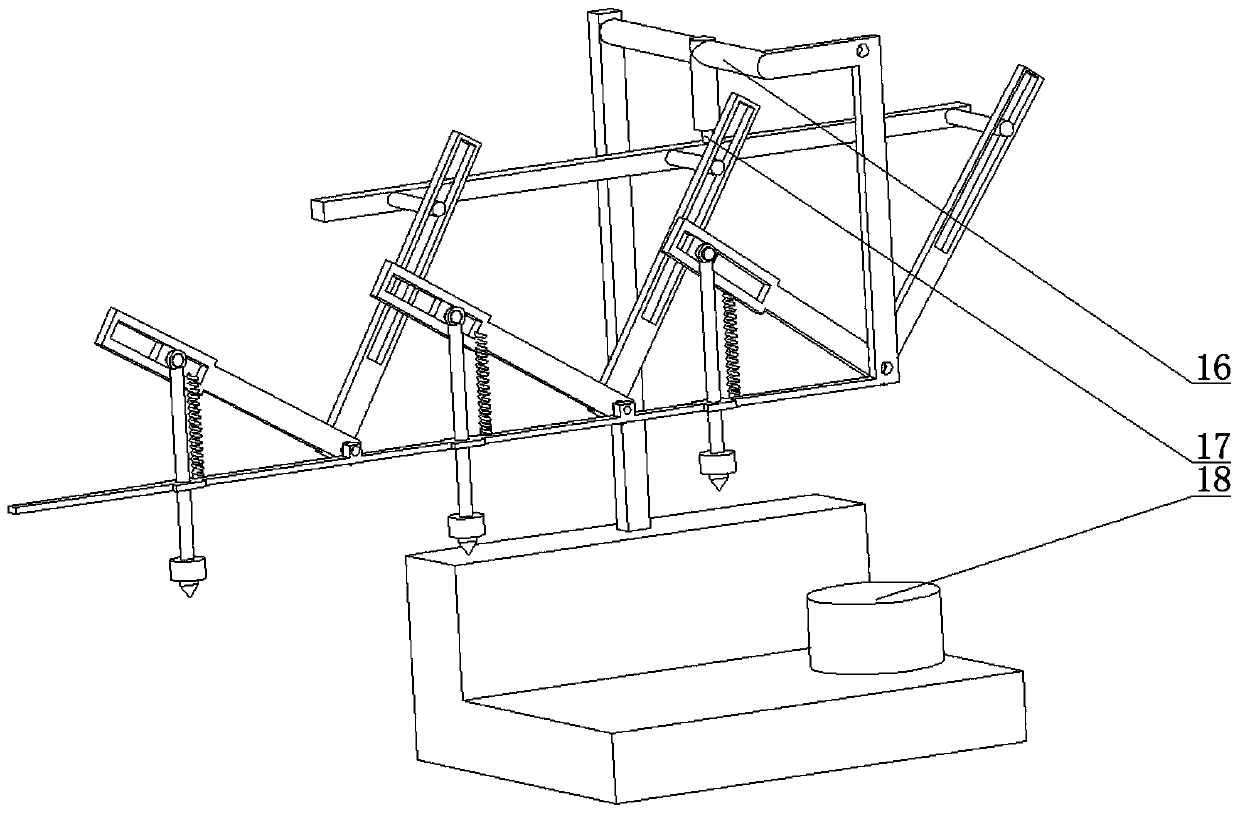

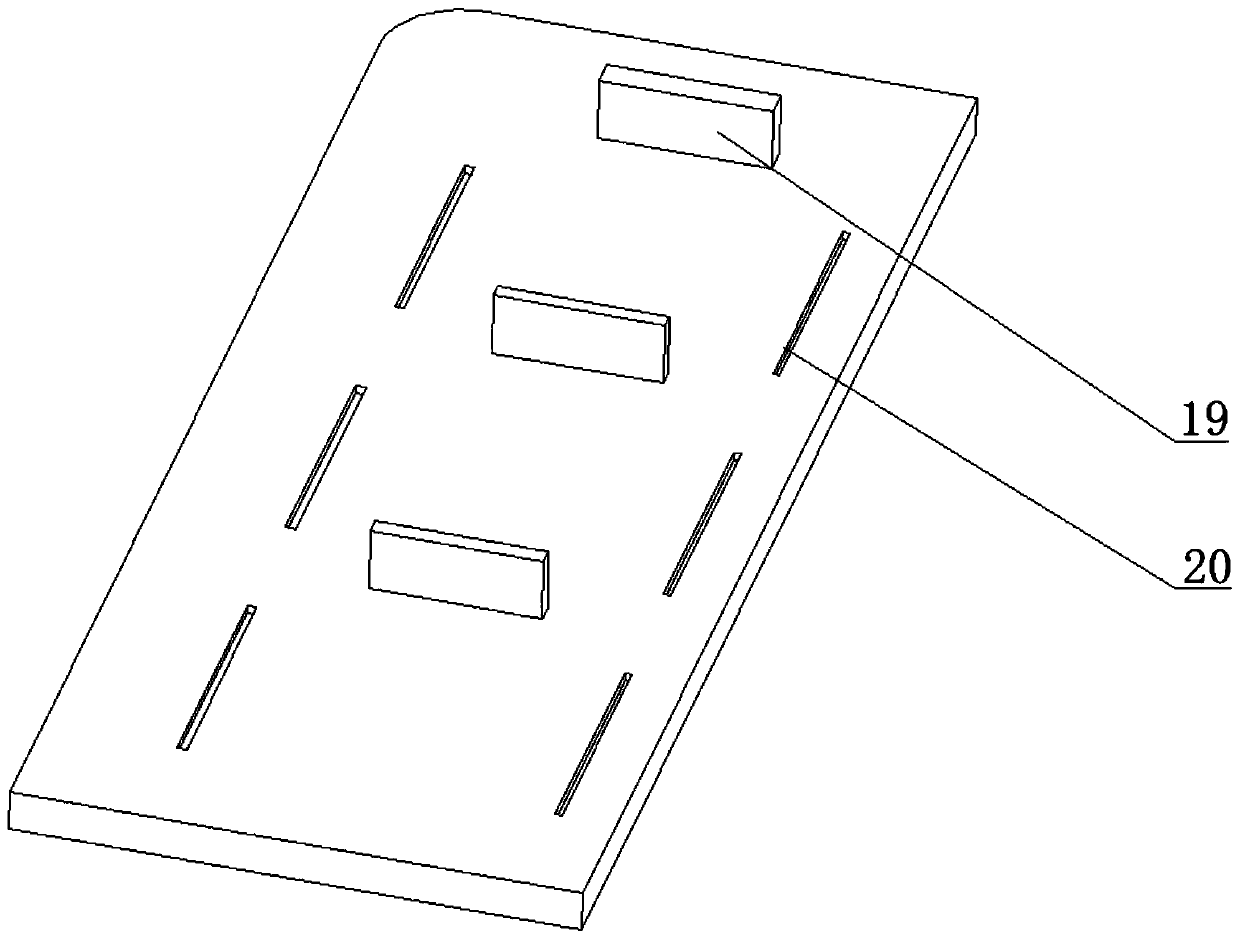

[0033] like Figure 1-Figure 10 As shown, the present invention comprises an L-shaped plate 8, the upper side of the horizontal plate of the L-shaped plate 8 is fixedly connected to a motor one 18, and the upper side of the vertical plate of the L-shaped plate 8 is fixedly connected to a vertical bar 14, and the upper side of the vertical bar 14 One end of the upper side is fixedly connected to the second round bar 16, the middle part of the second round bar 16 is fixedly connected to the hollow round bar 15, and the other end of the second round bar 16 is fixedly connected to one end of the upper cross bar of the U-shaped bar 4. The output shaft of the second motor 18 is hinged to one corner of the support plate 7, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com