Metal pipe fitting casting device and casting method

A technology for metal pipe fittings and round pipes, which is applied in the field of metal pipe fitting casting devices, can solve problems such as difficult demoulding, and achieve the effects of rapid demoulding and solving difficult demoulding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

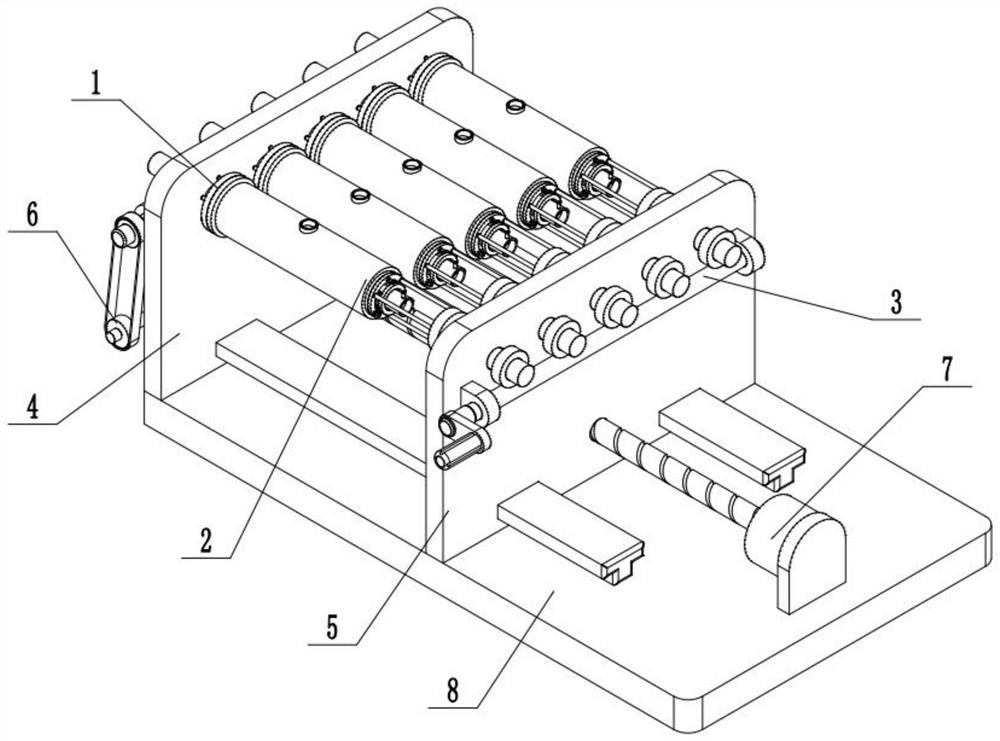

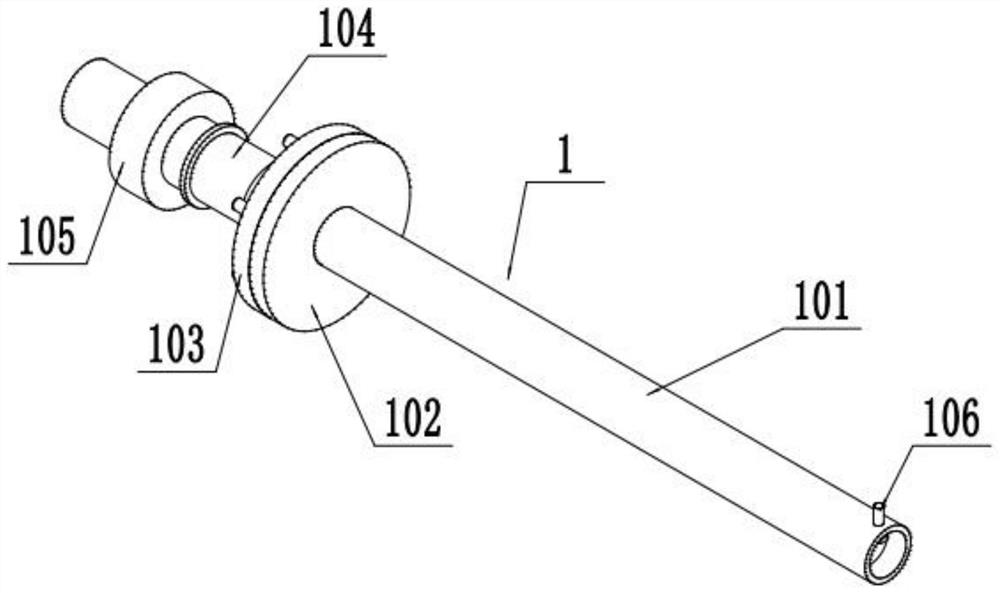

[0033] Such as Figure 1-11 As shown, a metal pipe casting device includes a round rod mold 1, a round pipe mold 2, a hand control mechanism 3, a fixed stand 4, a movable stand 5, a linkage wheel set 6, a drive mechanism 7 and a frame 8, Described round bar mold 1 is provided with a plurality of, and the left end of a plurality of round bar molds 1 is rotatably connected on the fixed stand 4; On the movable stand 5; the right end of a plurality of round rod molds 1 rotates and fits on the left end of a plurality of round tube molds 2; the fixed stand 4 is fixed on the left end of the top surface of the frame 8; the movable stand 5 slides Cooperate with the right end of frame 8 top surface; Described drive mechanism 7 is connected on the right end of frame 8; on the frame 4; the driving mechanism 7 is connected to the linkage wheel set 6; the linkage wheel set 6 is connected to the fixed stand 4; the linkage wheel set 6 is connected to a plurality of round rod molds 1 through ...

specific Embodiment approach 2

[0035] Such as Figure 1-11 As shown, the frame 8 is provided with a T-shaped slide rail 801; the movable stand 5 is slidably fitted on the T-shaped slide rail 801 through a T-shaped slot. The setting of the T-shaped slide rail 801 can improve the stability of the movable stand 5 when sliding on the frame 8 .

specific Embodiment approach 3

[0036] Such as Figure 1-11 As shown, the drive mechanism 7 includes a servo motor 701, a lead screw 702 and a transmission bevel gear 703; the servo motor 701 is fixed on the frame 8 through a motor base; the output shaft of the servo motor 701 is connected by a coupling One end of the lead screw 702 , the lead screw 702 is rotatably fitted on the fixed stand 4 , and the other end of the lead screw 702 is fixedly connected to the transmission bevel gear 703 ; After the servo motor 701 inside the drive mechanism 7 is powered on, it can drive the lead screw 702 to rotate. When the lead screw 702 rotates, it can drive the transmission bevel gear 703 to rotate, and the transmission bevel gear 703 can drive the linkage wheel group 6 to work; When the leading screw 702 rotates, the position where the leading screw 702 contacts with the movable stand 5 changes, and then drives the movable stand 5 to slide on the frame 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com