C-shaped closed angle beam forming tool and demolding method

A technology for forming tooling and closing angles, which is applied to household components, household appliances, other household appliances, etc., can solve the problems of easy damage to the surface of composite parts, high manufacturing and use costs, and bending of composite parts, saving manpower. The effect of operating time cost, reduction of mold release equipment, and reduction of manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

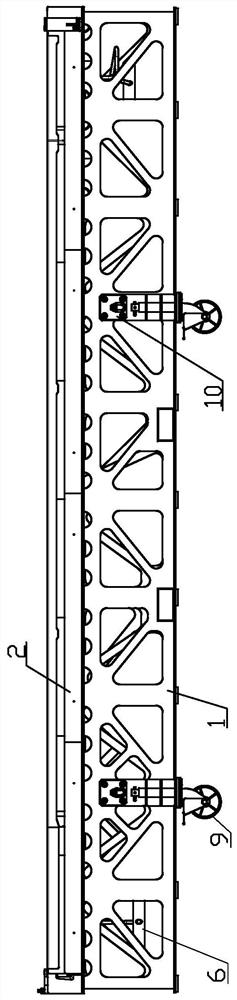

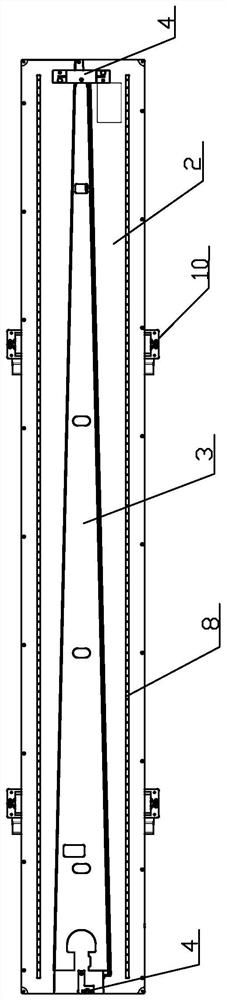

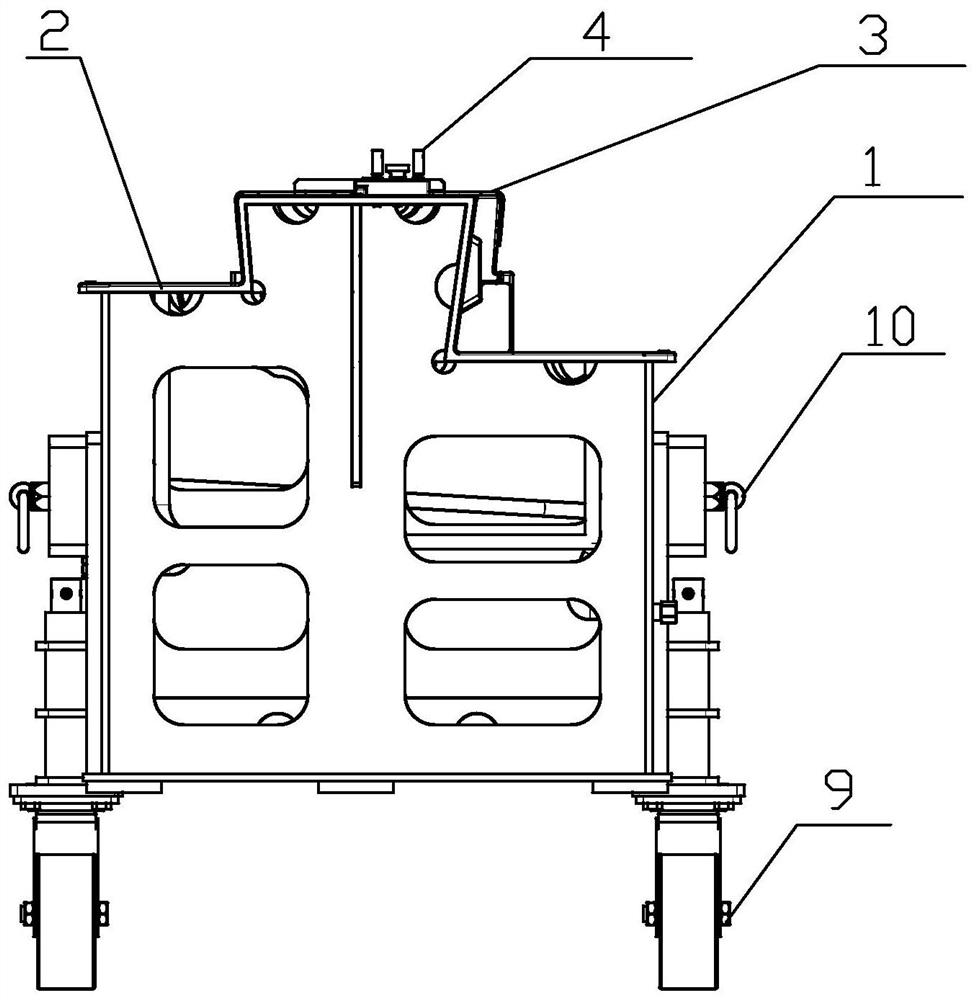

[0031] A C-shaped closed-angle beam forming tooling includes a frame 1 and a mold assembly 2, the mold assembly includes a plate one 21, a plate two 22, a plate three 23, a sub-block 24 and an insert 25, the plate one 21, plate The second plate 22 and the third plate 23 are sequentially connected to form a 'C'-shaped structure, the free ends of the first plate 21 and the third plate 23 are all inclined inwardly and fixed on the frame 1, and the sub-blocks 24 are arranged on the third plate 23 One side, and the upper surface is flush with the second plate 22 , the sub-block 24 is set inwardly away from the lower end of the side wall of the third plate 23 , and the insert 25 is arranged below the sub-block 24 .

[0032] Further, the acute angle between the side wall of the block 24 away from the third plate 23 and the vertical direction is greater than the acute angle between the edge strip 31 of the C-shaped closed angle beam 3 and the vertical direction.

[0033] Further, the ...

specific Embodiment approach 2

[0041] A method for demoulding a C-shaped closed-angle beam using the forming tool described in Embodiment 1, comprising the following steps:

[0042] Step 1. After the C-shaped closed-angle beam 3 is cured and molded in the autoclave on the molding tool, the tool is transferred to the open space to prepare for demoulding. First, the auxiliary materials used for curing the vacuum bag, isolation film, twist strip, etc. Peel it off from the tooling, and drill the craft lug hole at the reserved position of the drilling mold;

[0043] Step 2. When demoulding, take out the lower insert 25 along the width direction of the tooling;

[0044] Step 3, the demoulding block 24 is moved downwards, and then taken out along the width direction of the tooling to complete the demoulding of the C-shaped closed-angle beam.

[0045] Before designing the mold, measure the closed angle of the part (the acute angle between the edge strip 31 and the vertical direction) to be 5°, and the angle betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com