Dust remover for dumping furnace self-baking electrode volatile matter

A technology of self-baking electrodes and volatile matter, which is applied in separation methods, dispersed particle separation, dispersed particle filtration, etc., can solve problems such as joint fractures, achieve the effects of reducing pulling force, slowing down flow velocity, and increasing settlement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

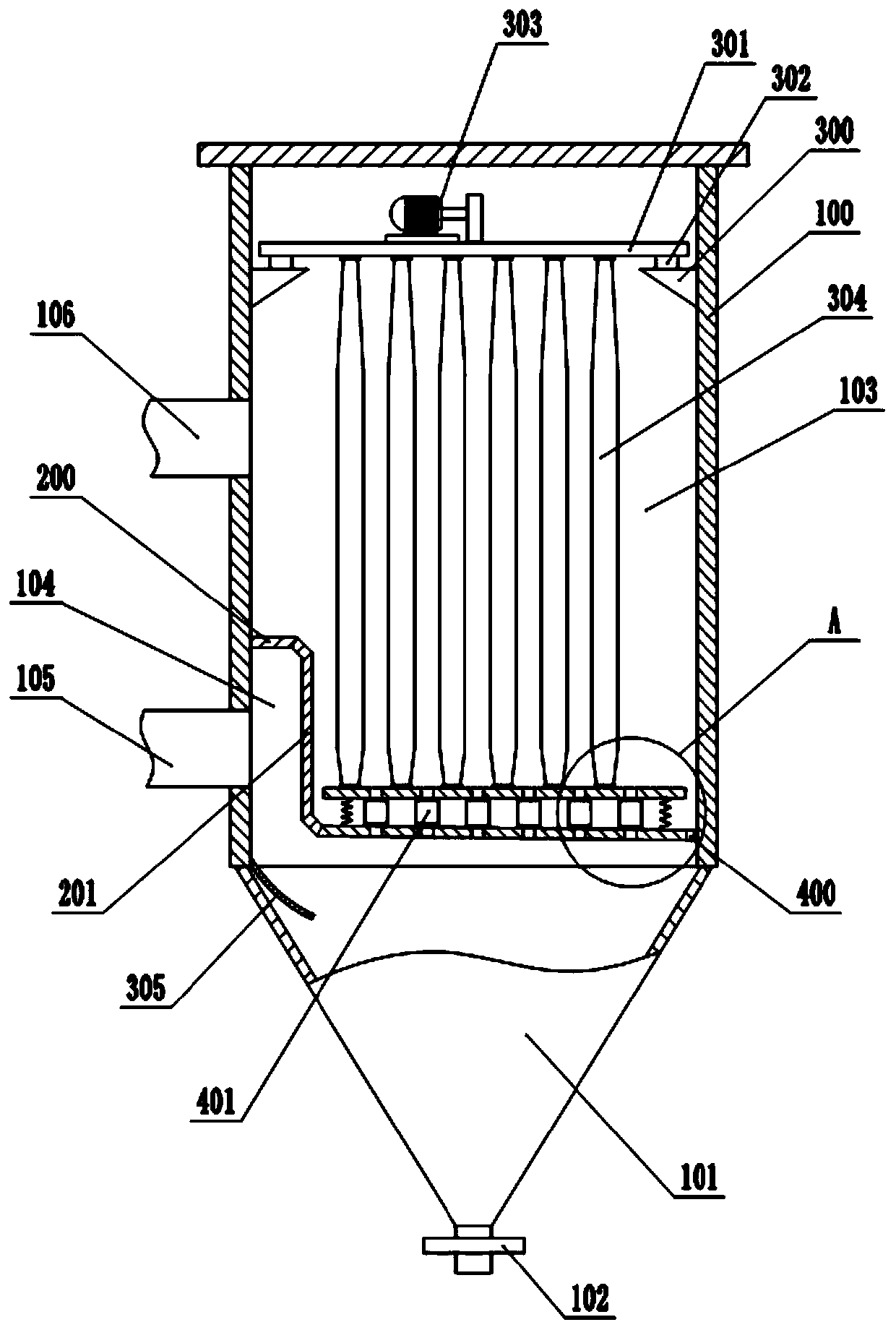

[0035] Embodiment 1 is basically as attached figure 1 Shown:

[0036] A dumping furnace self-baking electrode volatile dust collector, including a box 100 and an ash hopper 101, the ash hopper 101 is fixed below the box 100, the box 100 is supported on the ground by feet or directly fixed on the frame, the box The top and side walls of the body 100 are provided with inspection doors, the bottom of the ash hopper 101 is provided with a sliding door 102, and a partition is fixed horizontally in the box body 100, and the partition board divides the box body 100 into a clean room 103 and a cleaning room 104 , the box body 100 is provided with the air inlet 105 connected to the cleaning chamber 104 and the air outlet 106 connected to the clean room 103, the air inlet 105 and the air outlet 106 are all provided with valves, wherein the partition is Z-shaped, including the top plate 200 , the vertical plate 201 and the horizontal plate 202, the horizontal plate 202 is provided with ...

Embodiment 2

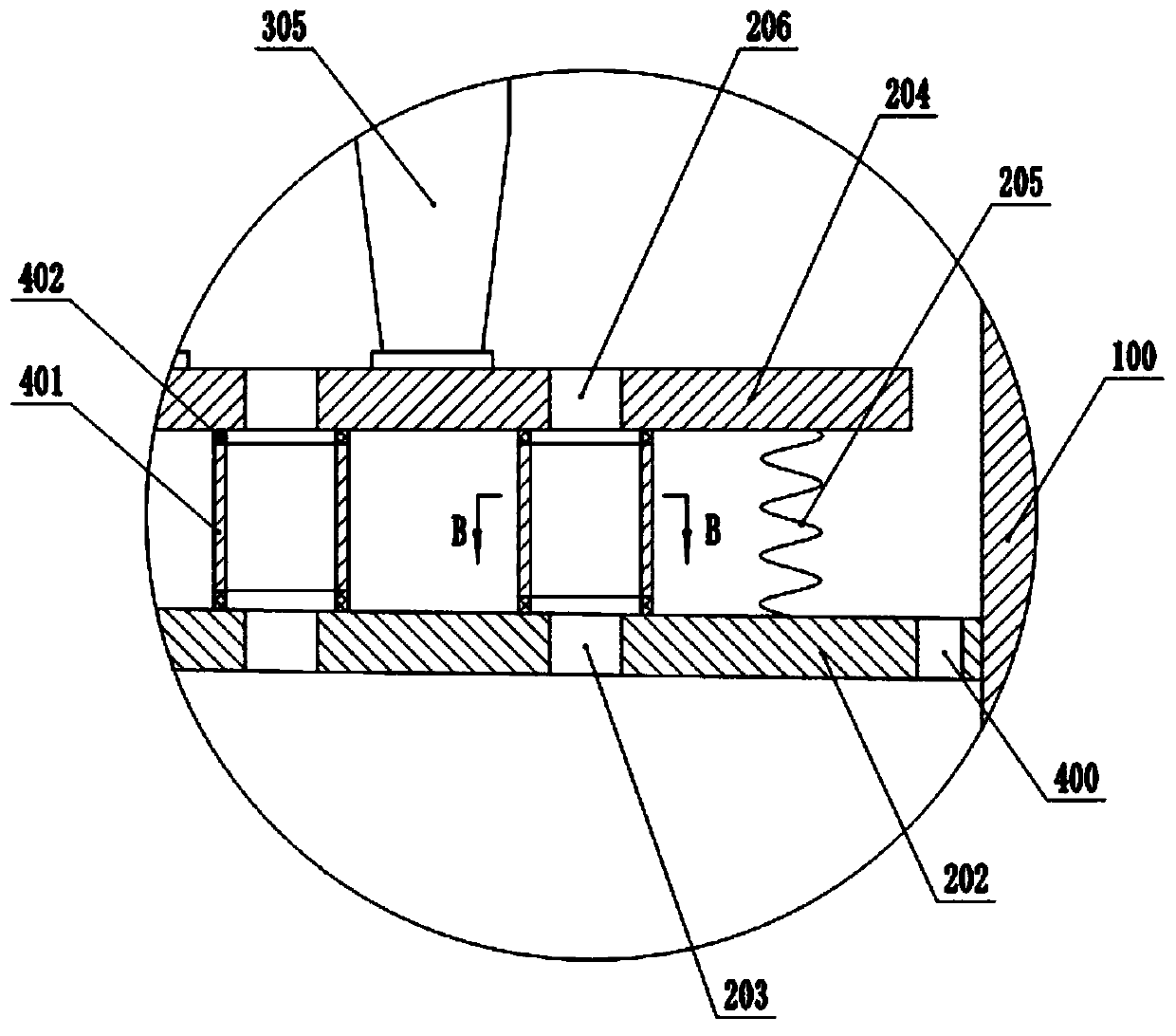

[0045] Embodiment 2 is basically as figure 2 Shown:

[0046] The difference from Embodiment 1 is that: the end of the horizontal plate 202 away from the air inlet 105 is inclined downward, and the horizontal plate 202 is provided with an ash discharge port 400 on the side away from the air inlet 105, and the through hole I and the through hole II are no longer Misalignment, that is, the adjacent through hole Ⅰ and through hole Ⅱ are set oppositely, and the intermediate pipe is a metal hard pipe 401 made of stainless steel. image 3 As shown, the upper and lower ends of the metal hard tube 401 are fixed with rubber rings 402, the rubber ring 402 at the upper end of the metal hard tube 401 is fixed with the buffer plate 204, and the rubber ring 402 at the lower end of the metal hard tube 401 is fixed with the horizontal plate 202, combined Figure 4 As shown, a horizontal shaft 403 is rotationally and sealedly connected to the side wall of the metal hard tube 401, and the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com