High-efficiency tea scenting device

A high-efficiency technology for tea, which is applied to the field of high-efficiency tea aroma-improving devices, can solve the problems of unsmooth hair loss, increased drying time, high labor intensity, etc., so as to improve the aroma-improving effect of tea, avoid extrusion and accumulation, and improve the evacuation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

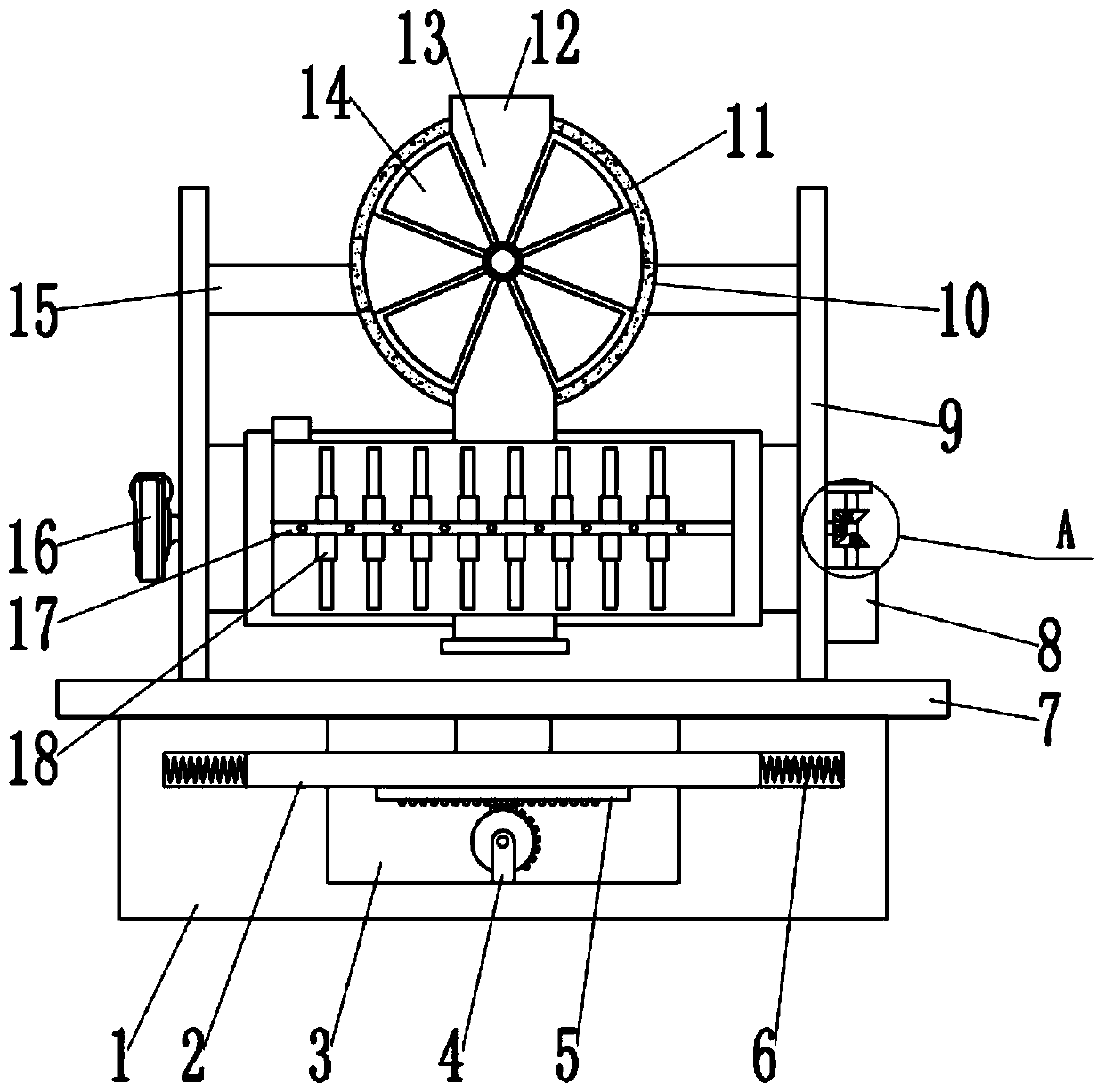

[0029] see Figure 1~4 , in the embodiment of the present invention, a high-efficiency tea aroma enhancing device includes a second base 7, an aroma enhancing mechanism and a preheating mechanism 10; two side plates 9 are symmetrically fixedly installed on the left and right sides of the second base 7, The aroma enhancing mechanism and the preheating mechanism 10 are installed between the two side plates 9, the preheating mechanism 10 is located above the aroma enhancing mechanism, and the preheating mechanism 10 communicates with the aroma enhancing mechanism through the feeding channel, and the tea leaves After being heated by the preheating mechanism 10, it is sent into the inside of the aroma enhancing mechanism to carry out aroma enhancement;

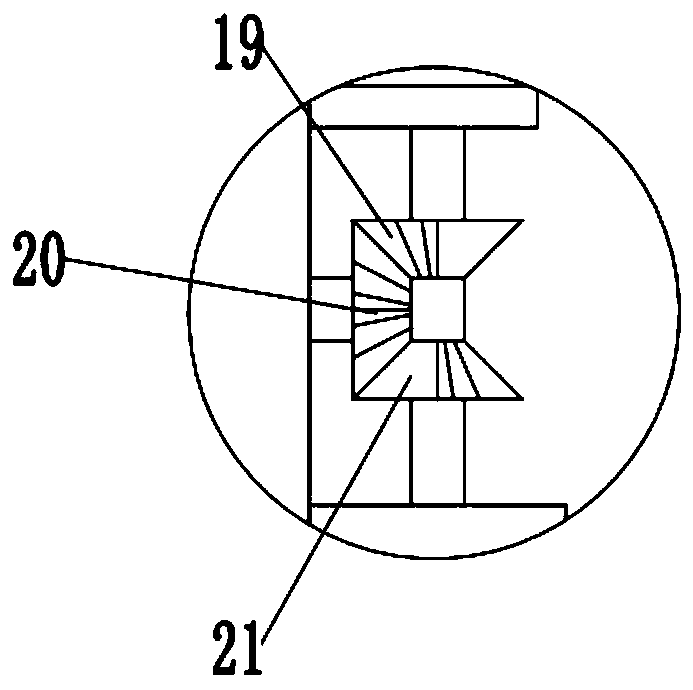

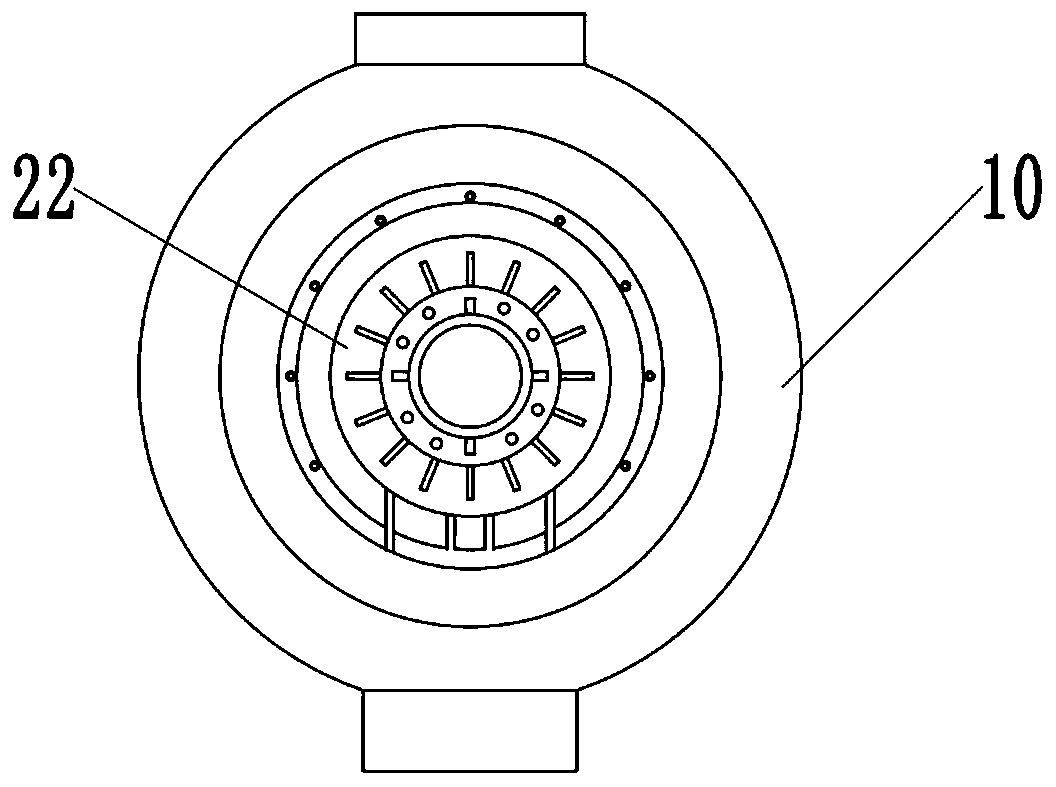

[0030] The preheating mechanism 10 includes a housing 11 and a turntable mounted on the inside of the housing 11. The upper part of the housing 11 has a feed port 12 for pouring tea leaves. The turntable is evenly provided with a n...

Embodiment 2

[0037]The difference between this embodiment and Embodiment 1 is that a first base 1 is provided under the second base 7, and the first base 1 is slidably connected to the second base 7; Slot 3, the inside of the installation slot 3 is rotated with a sector gear 4, and two chute troughs are symmetrically opened above the first base 1, and the left and right ends of the slide bar 2 are slidably installed inside the chute, and the The two ends are fixedly connected to the chute through the spring 6, the bottom of the slide bar 2 is fixedly installed with a rack 5, the rack 5 meshes with the sector gear 4, and the sector gear 5 meshes with the rack 5 intermittently when rotating, and then drives the slide bar 2 Slide left and right; the upper end of the slide bar 2 is fixedly connected with the second base 7, and when the slide bar 2 slides left and right, it drives the second base 7 to slide left and right, and then drives the aroma enhancing mechanism and the preheating mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com